System and method for pretreatment of wastewater in ethylene glycol production

A production wastewater and pretreatment technology, applied in the field of resources and environment, can solve problems such as high cost, difficult operation, management and maintenance, and difficult pretreatment, so as to reduce environmental protection costs, improve project operation and management level, and ensure smooth production and operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

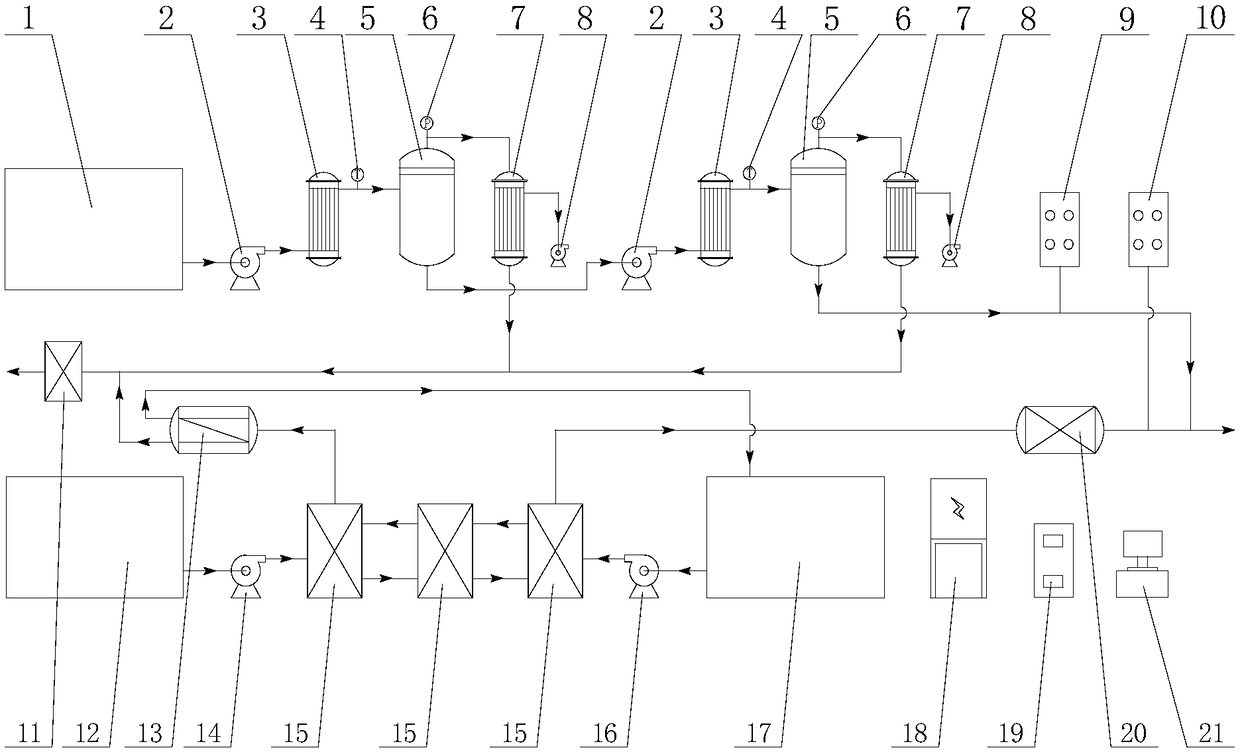

[0017] like figure 1 As shown, a kind of ethylene glycol production wastewater pretreatment system of the present invention comprises 2-methoxyethanol wastewater regulating tank 12, 2-methoxyethanol wastewater circulation pump 14, extractant circulation pump 16, Hydrocarbon extractant storage tank 17, at least one-stage extraction device 15, extraction phase separation device 13, raffinate phase treatment device 20, methylal-containing wastewater regulating tank 1, at least one-stage vacuum distillation system, fuel proportional mixer 11 , automatic control cabinet 18, remote thermometer 4, remote vacuum gauge 6, online monitoring and early warning device for biotoxicity of wastewater containing methylal 9, online monitoring and early warning device for biotoxicity of wastewater containing 2-methoxyethanol 10, signal conversion device 19 And remote monitoring terminal 21, wherein each stage of vacuum distillation system includes methylal-containing wastewater circulation pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com