A kind of water-resistance special agent for gypsum

A water-resistant agent and gypsum technology, which is applied in the field of gypsum admixture and gypsum deep processing, can solve problems affecting stability, large organic component content, complex preparation process, etc., achieve good applicability, improve water resistance and strength, and have obvious effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

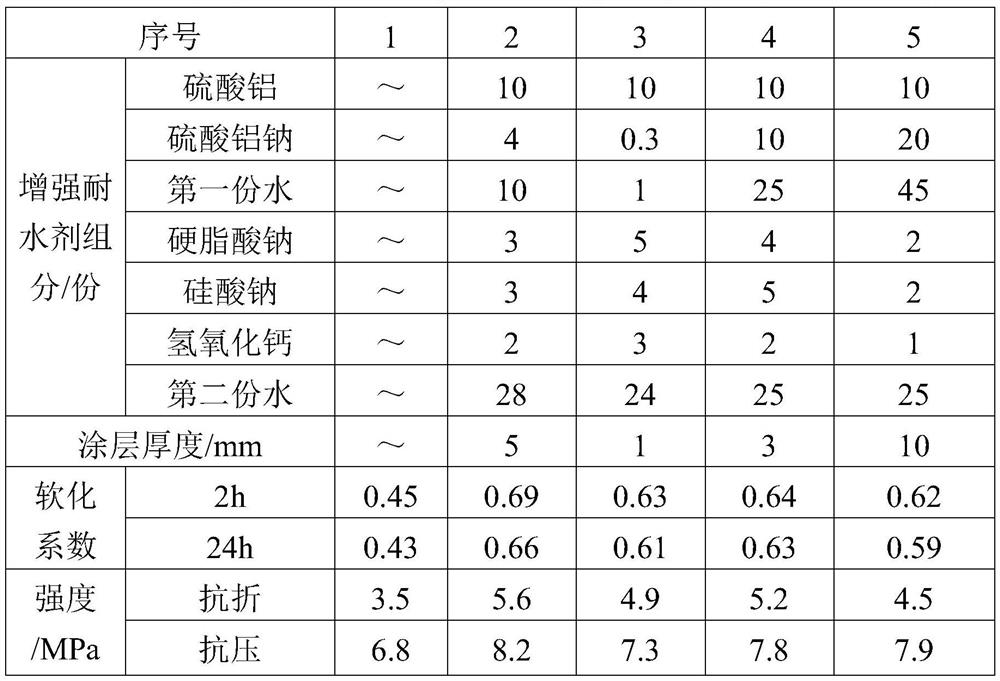

[0034]The preparation method of the special enhanced water-resistant agent for gypsum and the treatment method of gypsum products of this embodiment are as follows:

[0035]1) Dissolve sodium aluminum sulfate reagent in the first part of water at 80℃~90℃ to make sodium aluminum sulfate solution;

[0036]2) Add aluminum sulfate, sodium stearate, sodium silicate, and calcium hydroxide to the above-mentioned sodium aluminum sulfate solution at 80-90°C, stir evenly, and add a second portion of water until the solutes are completely dissolved, and cool to room temperature , That is, a special enhanced water-resistant agent solution for gypsum; the total weight of the first part of water and the second part of water is 25 to 70 parts;

[0037]3) Select the surface gypsum prepared by building gypsum powder as the matrix, and after dust removal treatment on the surface of the surface gypsum plaster, evenly coat the surface with a layer of enhanced water-resistant agent solution with a penetration de...

Embodiment 2

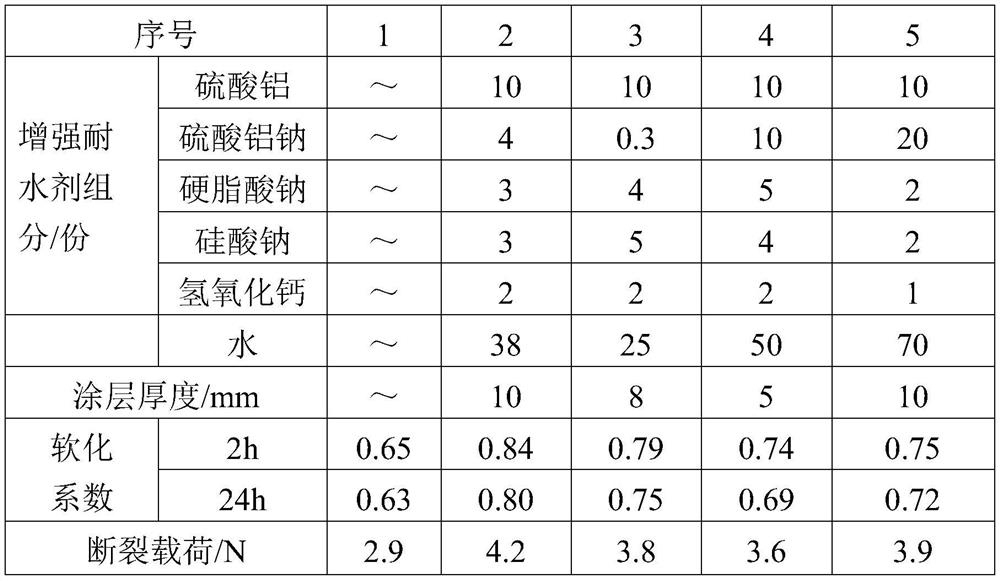

[0043]The preparation method of the special enhanced water-resistant agent for gypsum and the processing method of gypsum products of this embodiment are as follows:

[0044]1) Using aluminum sulfate + sodium sulfate method, that is, after aluminum sulfate is completely dissolved in 25 to 70 parts of water at 80°C, sodium sulfate is added to the resulting aluminum sulfate solution and reacted at 80 to 90°C to prepare sulfuric acid Aluminum sodium solution;

[0045]As Na2SO4+Al2(SO4)3=2NaAl(SO4)2Therefore, when the aluminum sulfate+sodium sulfate method is used to prepare sodium aluminum sulfate solution, the weight parts of sodium aluminum sulfate are converted into weight parts of aluminum sulfate and sulfuric acid according to the weight ratio of the water-resistant agent. The weight parts of sodium, respectively weigh aluminum sulfate and sodium sulfate according to the converted weight parts, and then dissolve and react to prepare a sodium aluminum sulfate solution;

[0046]2) Add alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com