Millimeter-level zirconium oxide particle preparation method for application in chemical protection field

A technology of zirconia particles and chemical protection, applied in zirconia, nanotechnology for materials and surface science, nanotechnology, etc., to achieve good cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A method for preparing millimeter-sized zirconia particles for application in the field of chemical protection, comprising the following steps:

[0017] 1. Synthesis of high specific surface nano zirconia

[0018] Zirconium oxychloride is used as zirconium source, fatty acid methyl ester ethoxylate is used as template agent, and ammonium bicarbonate is used as precipitating agent; 0.2-0.6mol / L ammonium bicarbonate solution is slowly dropped into 20-30mL fatty acid at room temperature In the methyl ester ethoxylate solution, fully stir for 20 minutes, then add this mixed solution into 0.2-0.4mol / L zirconium oxychloride solution while stirring, and stir with magnetic force for 30 minutes; hydrothermal synthesis reaction at 140°C for 10-12 hours ; After cooling, the solid precipitate is placed on a surface dish and dried at room temperature for 24-48 hours, and then placed in a muffle furnace for high-temperature calcination at a calcination temperature of 300-380°C;

[0...

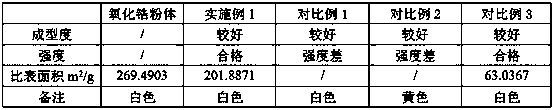

Embodiment 1

[0021] Example 1: 10g of zirconia powder, 5g of carboxymethyl cellulose, 10mL of water, mix well, stir, press into a cake shape, dry at room temperature for 24h, dry and calcinate in an oven at 140°C;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com