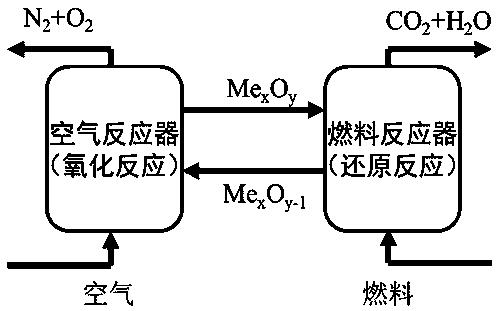

Preparation method of core-shell structure Fe2O3-CeO2/(Al@C) high-temperature composite phase-change heat accumulation oxygen carrier

A fe2o3-ceo2, composite phase transition technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of decreased reaction rate, unfavorable cycle operation, low reaction rate, etc., to prevent leakage, high mechanical strength, Enhance the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

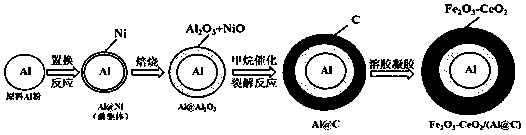

[0044] Embodiment 1: as figure 2 As shown, a core-shell Fe 2 o 3 -CeO 2 / (Al@C) The preparation method of high-temperature composite phase change heat storage oxygen carrier, the specific steps are:

[0045] (1) Aluminum powder, NiCl 2 , NH 4 F is added to water to prepare aluminum powder turbid liquid, NiCl 2 solution and NH 4 F solution; including aluminum powder, NiCl 2 , NH 4 The molar ratio of F is 15:1.6:2, the concentration of aluminum powder in the aluminum powder turbid solution is 1.5mol / L, NiCl 2 NiCl in solution 2 The concentration is 0.16mol / L, NH 4 NH in F solution 4 The concentration of F is 0.2mol / L;

[0046] (2) Place the aluminum powder turbid solution in step (1) in an ultrasonic wave with a power of 70W and perform ultrasonic treatment for 10 minutes to obtain an aluminum powder suspension;

[0047] (3) Add gelatin to the NiCl in step (1) 2 solution, in which gelatin and NiCl 2 The solid-to-liquid ratio g:L of the solution is 10:1, stir even...

Embodiment 2

[0057] Embodiment 2: a kind of core-shell structure Fe 2 o 3 -Al 2 o 3 / (Al@C) The preparation method of high-temperature composite phase change heat storage oxygen carrier, the specific steps are:

[0058] (1) Aluminum powder, NiCl 2 , NH 4 F is added to water to prepare aluminum powder turbid liquid, NiCl 2 solution and NH 4 F solution; including aluminum powder, NiCl 2 , NH 4 The molar ratio of F is 5:0.5:1, the concentration of aluminum powder in the aluminum powder turbid solution is 0.5mol / L, NiCl 2 NiCl in solution 2 The concentration is 0.05mol / L, NH 4 NH in F solution 4 The concentration of F is 0.1mol / L;

[0059] (2) Place the aluminum powder turbid solution in step (1) in an ultrasonic wave with a power of 40W and perform ultrasonic treatment for 5 minutes to obtain an aluminum powder suspension;

[0060] (3) Add gelatin to the NiCl in step (1) 2 solution, in which gelatin and NiCl 2 The solid-to-liquid ratio g:L of the solution is 3:1, stir evenly at...

Embodiment 3

[0070] Embodiment 3: a kind of core-shell structure Fe 2 o 3 -Al 2 o 3 / (Al@C) The preparation method of high-temperature composite phase change heat storage oxygen carrier, the specific steps are:

[0071] (1) Aluminum powder, NiCl 2 , NH 4 F is added to water to prepare aluminum powder turbid liquid, NiCl 2 solution and NH 4 F solution; including aluminum powder, NiCl 2 , NH 4 The molar ratio of F is 20:2:3, the concentration of aluminum powder in the aluminum powder turbid solution is 2mol / L, NiCl 2 NiCl in solution 2 The concentration is 0.2mol / L, NH 4 NH in F solution 4 The concentration of F is 0.3mol / L;

[0072] (2) Place the aluminum powder turbid solution in step (1) in an ultrasonic wave with a power of 80W for 30 minutes to obtain the aluminum powder suspension;

[0073] (3) Add gelatin to the NiCl in step (1) 2 solution, in which gelatin and NiCl 2 The solid-to-liquid ratio g:L of the solution is 15:1, stir evenly at a temperature of 55°C, then add t...

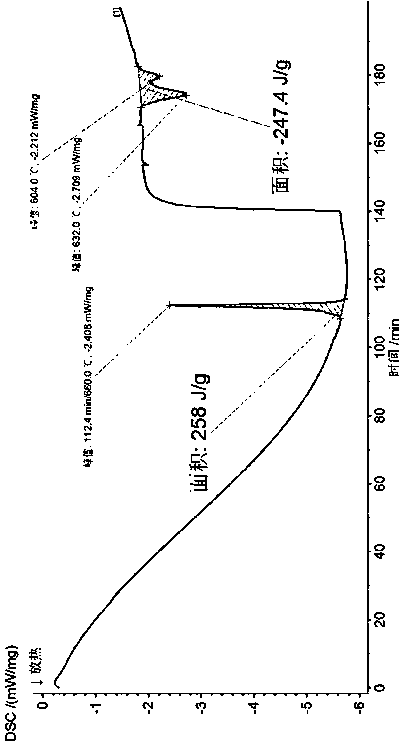

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| enthalpy of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com