Coal water slurry gasification system and coal water slurry gasification process based on phase-change-free heat exchange and black water heating

A technology of gasification system and coal-water slurry, which is applied in chemical industry, sustainable manufacturing/processing, granular/powdered fuel gasification, etc., can solve the problem of unusable low-grade steam heat, easy fouling and blockage of heat exchangers, The problems of high investment in flash evaporation equipment can achieve the effect of improving energy utilization efficiency, improving system reliability and online rate, and reducing operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

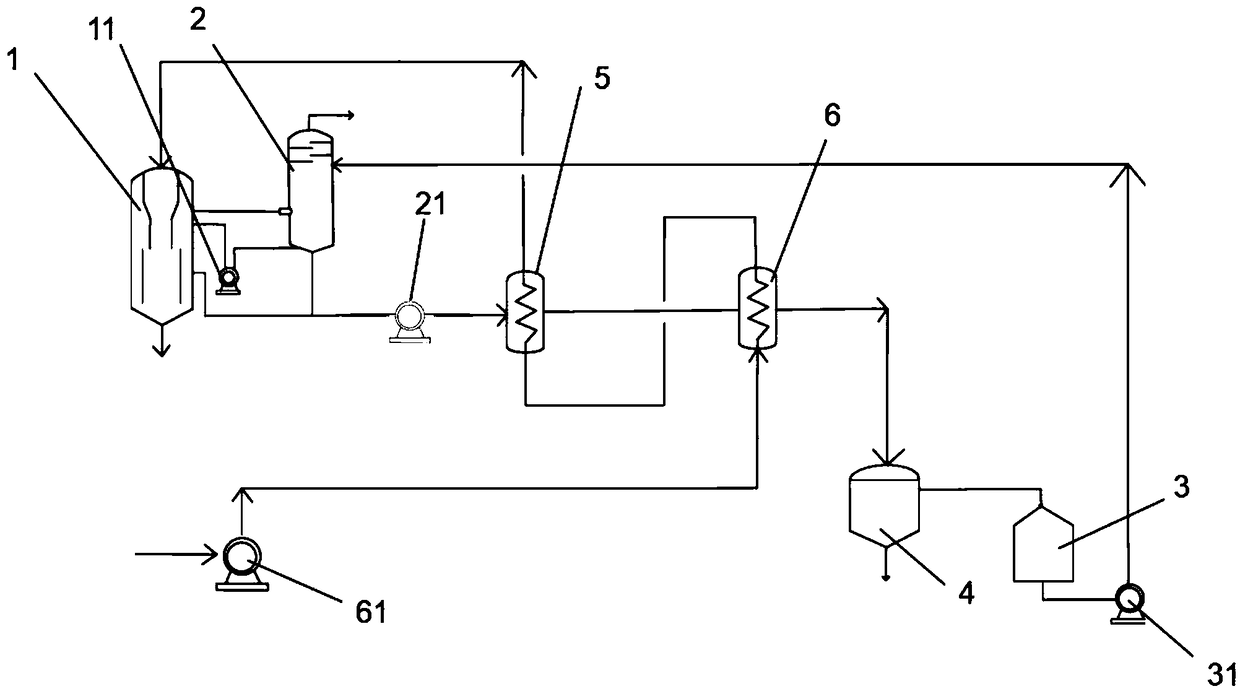

[0036] like figure 1 As shown, it is a schematic structural diagram of a black water heating coal-water slurry gasification system without phase change heat exchange. The gasifier 1, the washing tower 2, the gray water tank 3, and the settling tank 4 are arranged in sequence and connected by pipelines. The first coal water slurry / black water heat exchanger 5 is connected with the second coal water slurry / black water heat exchanger 6, gasifier 1 and washing tower 2 respectively, and the second coal water slurry / black water heat exchanger 6 It is also connected with the settling tank 4. Among them, the first coal-water slurry / black water heat exchanger 5 and the second coal-water slurry / black water heat exchanger 6 are new non-fouling heat exchangers, and both choose shell-and-tube non-fouling heat exchange The internal heat exchange tubes are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com