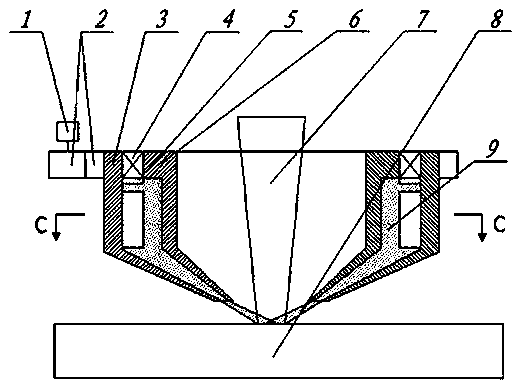

Coaxial powder feeding laser 3D printing laser cladding head

A 3D printing and laser cladding technology, applied in metal material coating technology, coating, additive processing, etc., can solve the problem of increasing process complexity, poor powder uniformity, affecting the performance of laser 3D printing and cladding layers, etc. problem, to achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

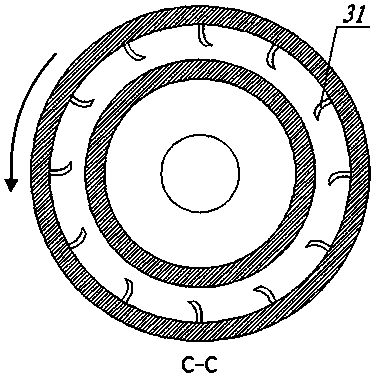

Method used

Image

Examples

Embodiment 1

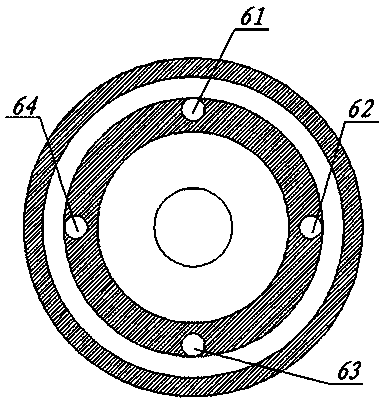

[0018] Cladding a layer of Al with a thickness of 0.5mm on the surface of 45 steel 2 o 3 / TiO 2 Ceramic coating, using a 3000 watt continuous fiber laser, the diameter of the laser spot after focusing is 3mm, the powder delivered by the powder feeding hole 1 and the powder feeding hole 3 is Al with a particle size of 50 mesh 2 o 3 Powder, powder feeding speed is 2cm 3 / s, the powder conveyed by the powder feeding hole 2 and the powder feeding hole 4 is TiO with a particle size of 200 mesh 2 , the powder feeding speed is 0.8cm 3 / s, the carrier gas pressure of the powder is 0.4MPa, and the rotating speed of the shell is 200r / min. After laser cladding, after testing, Al with a volume ratio of 5:2 and a uniform composition was obtained on the surface of 45 steel. 2 o 3 / TiO 2 Composite ceramic coating.

Embodiment 2

[0020] On the surface of 45 steel, the laser 3D printing functional gradient composite material is used. The lower layer is Mo2FeB2, and gradually transitions to the WC reinforced Mo2FeB2 composite material with a volume content of 25% on the surface layer, with a thickness of 3mm. A 100-watt continuous fiber laser is used. After focusing The diameter of the laser spot is 0.1mm. The powder conveyed by powder feeding hole 1 and powder feeding hole 3 is Mo2FeB2 powder with a particle size of 50 mesh, and the powder conveyed by powder feeding hole 2 and powder feeding hole 4 is WC with a particle size of 200 mesh. 0.4MPa, using layer-by-layer printing (the powder feeding speed of powder feeding hole 1 and powder feeding hole 3 of the first layer is 0.4cm 3 / min, the powder feeding speed of powder feeding hole 2 and powder feeding hole 4 is 0cm 3 / min; the powder feeding speed of powder feeding hole 1 and powder feeding hole 3 of the second layer is 0.39cm 3 / min, the powder feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com