Gas jet limit liquid absorption method

A gas jet, extreme technology, applied in the directions of jet pump, earthwork drilling, dust prevention, etc., can solve the problems of unstable system operation, burning coal resources, unstable liquid absorption, etc., to ensure the safe production of mines, and the prospect of application and promotion The effect of wide and improved equipment applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

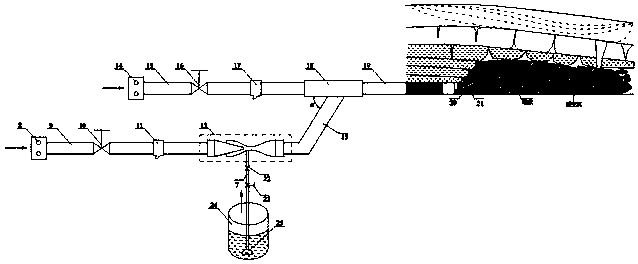

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

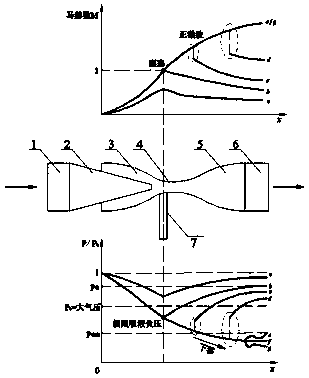

[0020] like figure 1 As shown in the figure, the invention discloses a gas jet limit suction method, the working principle of which is as follows: when the subsonic gas flow enters the jet nozzle (2) through the inlet rectifier tube (1), due to the reduction of the jet cross-sectional area, the gas flow velocity gradually increases , and reaches the local speed of sound near the nozzle outlet. At this time, the airflow Mach number M=1, and the high-speed turbulent gas jet forms a strong boundary effect. 4) The lowest negative pressure is reached near the front end, such as figure 1 Changes in (a) to (b) in .

[0021] Reduce the ratio of jet outlet back pressure to inlet pressure P b / P 0 , the Mach number M will break through 1 in the jet diffusion tube (5) to reach supersonic flow, and a normal shock wave will appear in the diffusion tube (5), and the pressure, ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com