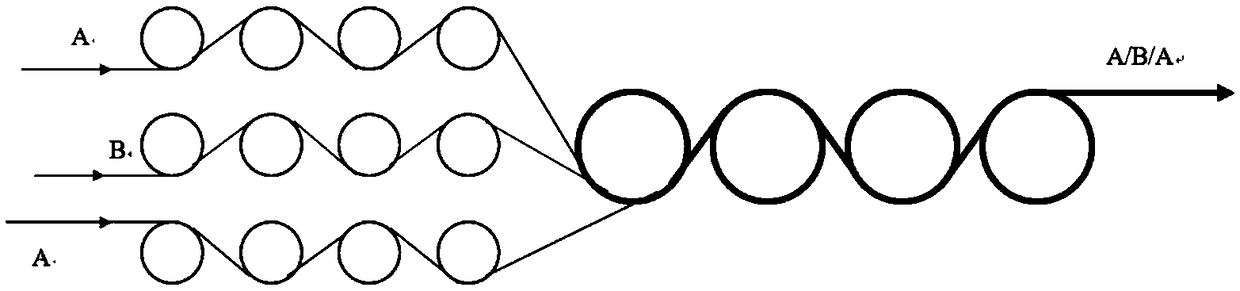

A porous multilayer composite diaphragm and a preparation method thereof

A multi-layer composite and diaphragm technology, which is applied to polypropylene/polyethylene/polypropylene porous multi-layer composite diaphragm and its preparation, and the field of porous multi-layer composite diaphragm and its preparation, can solve the increase of cost and the reduction of ionic conductivity , poor uniformity of micropores, etc., to achieve the effect of good uniformity and consistency, good pore size retention, and high interface consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

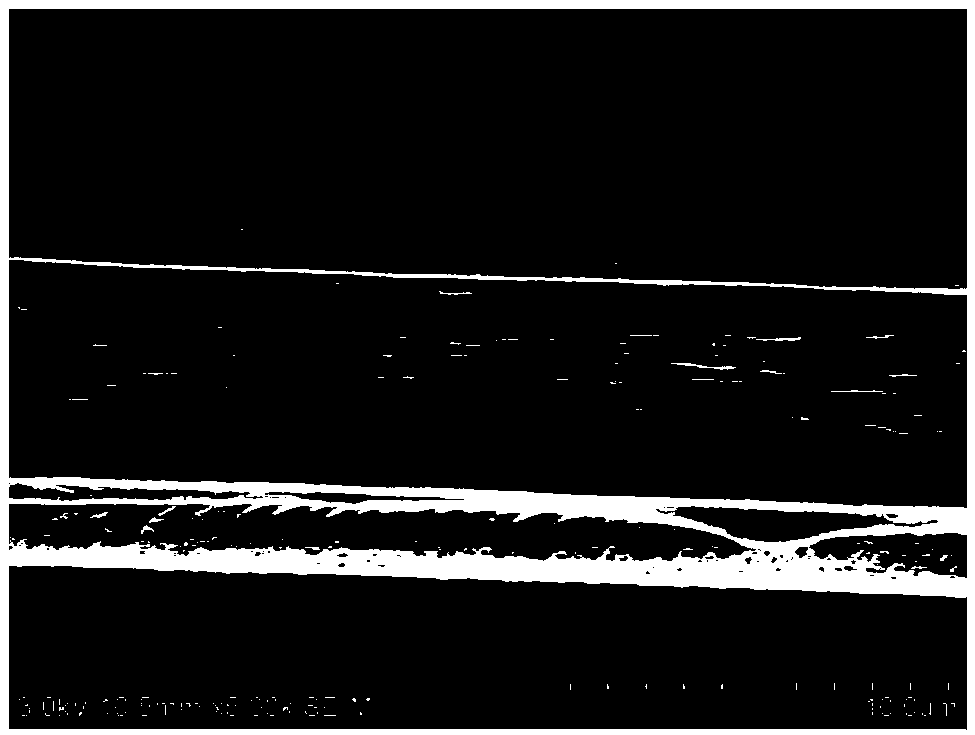

Examples

Embodiment 1

[0050] (1) Material preparation: the density is 0.91-0.93g / cm 3 , Polypropylene (PP) with a molecular weight of 300,000 is used as the surface layer polypropylene raw material. The density is 0.94-0.96g / cm 3 , High-density polyethylene (PE) with a molecular weight of 400,000 is used as the high-density polyethylene raw material for the core layer.

[0051] (2) Preparation of PP cast film: use a single-screw extruder with an aspect ratio L / D≥34 to melt and extrude polypropylene raw materials, and the extrusion temperature is between 160-230°C. After the melt is filtered and metered, it enters the flat die head, flows out from the die lip to form a sheet, and adheres to the casting roller to form a hard elastic casting film with a film thickness of 8-30 microns. Wherein the die draft ratio DDR is 80-180, and the casting roll temperature is 70-120°C.

[0052] (3) Preparation of PE casting film: use a twin-screw extruder with an aspect ratio L / D≥32 to melt and extrude high-dens...

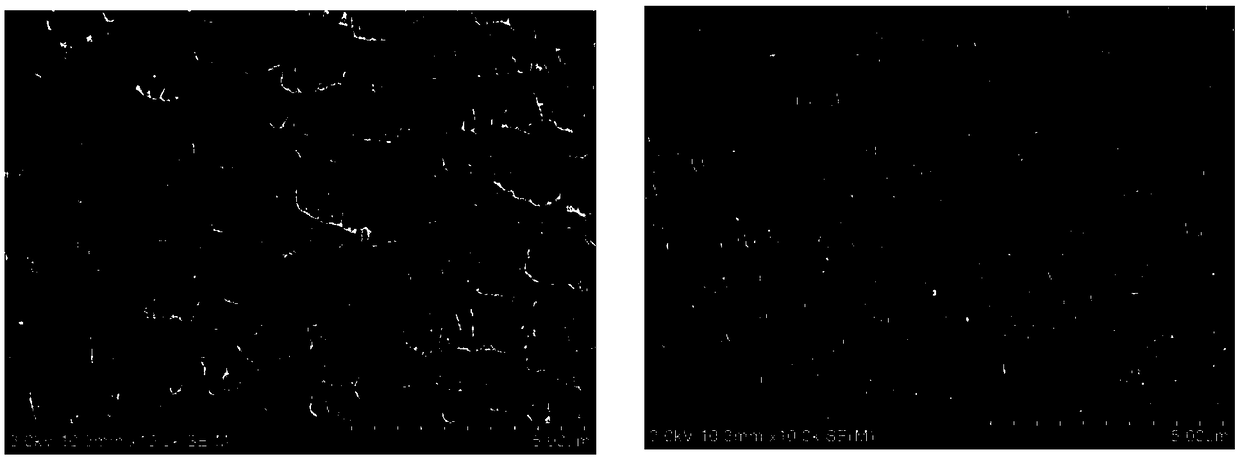

Embodiment 2

[0059] This example uses the same materials and process steps as in Example 1, but in step (5), the stretching speed ratio of the PP layer is 2.1-2.3, and the stretching speed ratio of the PE layer is 1.8-2.0, and PP / PE / PP is obtained Porous multilayer composite separator.

[0060] The obtained porous multi-layer composite diaphragm has been determined to have an average porosity of 37%, wherein the porosity of the PP layer is 40%, the porosity of the PE layer is 35%; the air permeability is 322s / 100ml; It is 0.32% / week, and the capacity retention rate is 93% after 1C cycle for 2000 cycles.

Embodiment 3

[0062] This example uses the same materials and process steps as Example 1, but in step (5), the stretching speed ratio of the PP layer is 2.8-3, and the stretching speed ratio of the PE layer is 1.6-1.8, and PP / PE / PP is obtained Porous multilayer composite separator.

[0063] The obtained porous multi-layer composite diaphragm is measured, with an average porosity of 37%, wherein the porosity of the PP layer is 49%, the porosity of the PE layer is 30%; the air permeability is 291s / 100ml; It is 0.21% / week, and the capacity retention rate is 91% after 1C cycle for 2000 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com