A DC/DC converter maximum inductor current sharing control method

An inductive current, converter technology, applied in the direction of converting DC power input to DC power output, control/regulation systems, instruments, etc., can solve the problems of system current sharing failure, system output interruption, reliability instability, etc. Dynamic performance, the effect of simplifying the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the present invention will be further described below in conjunction with the accompanying drawings:

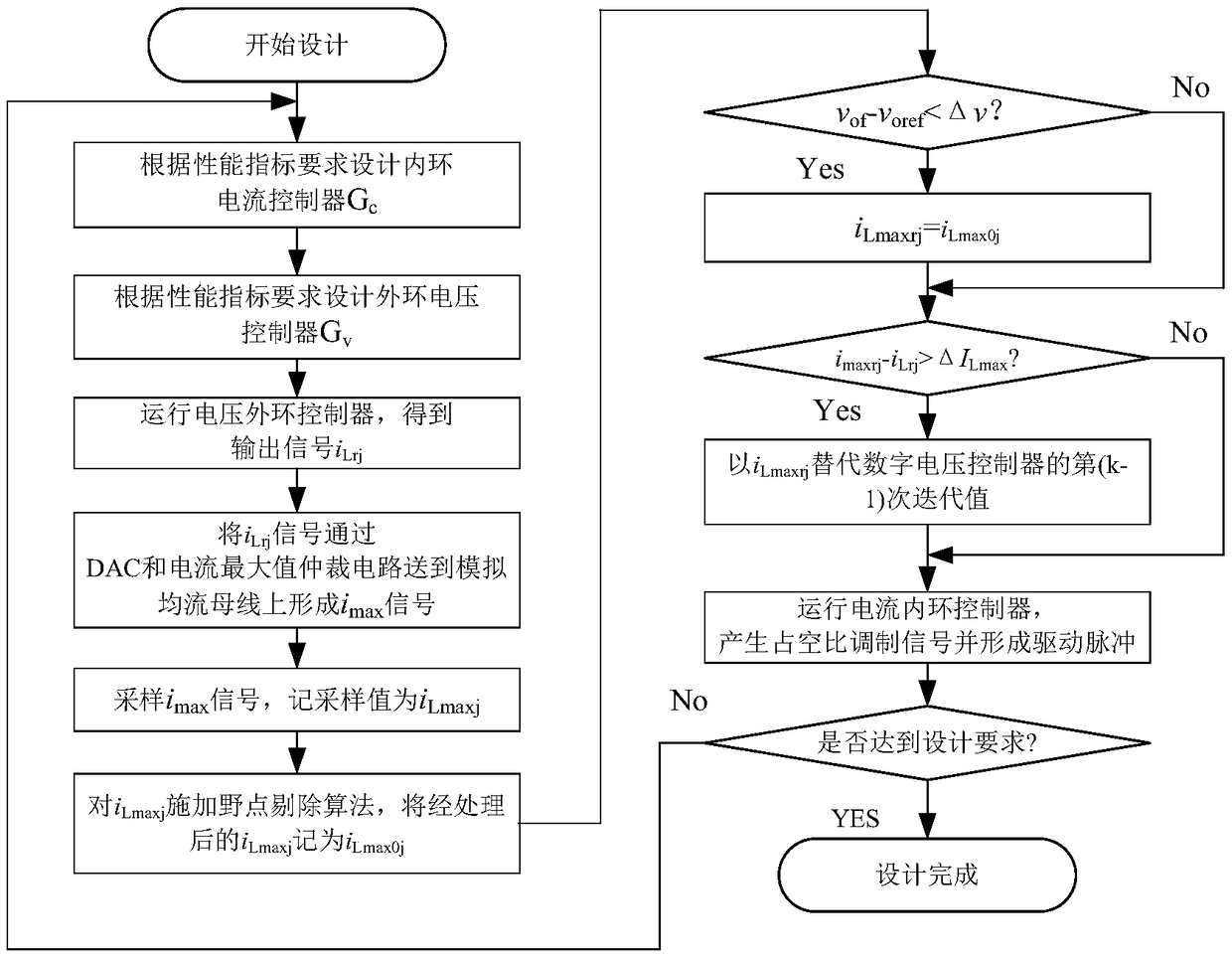

[0045] figure 1 It is a flow chart of a DC / DC converter maximum inductor current sharing control method;

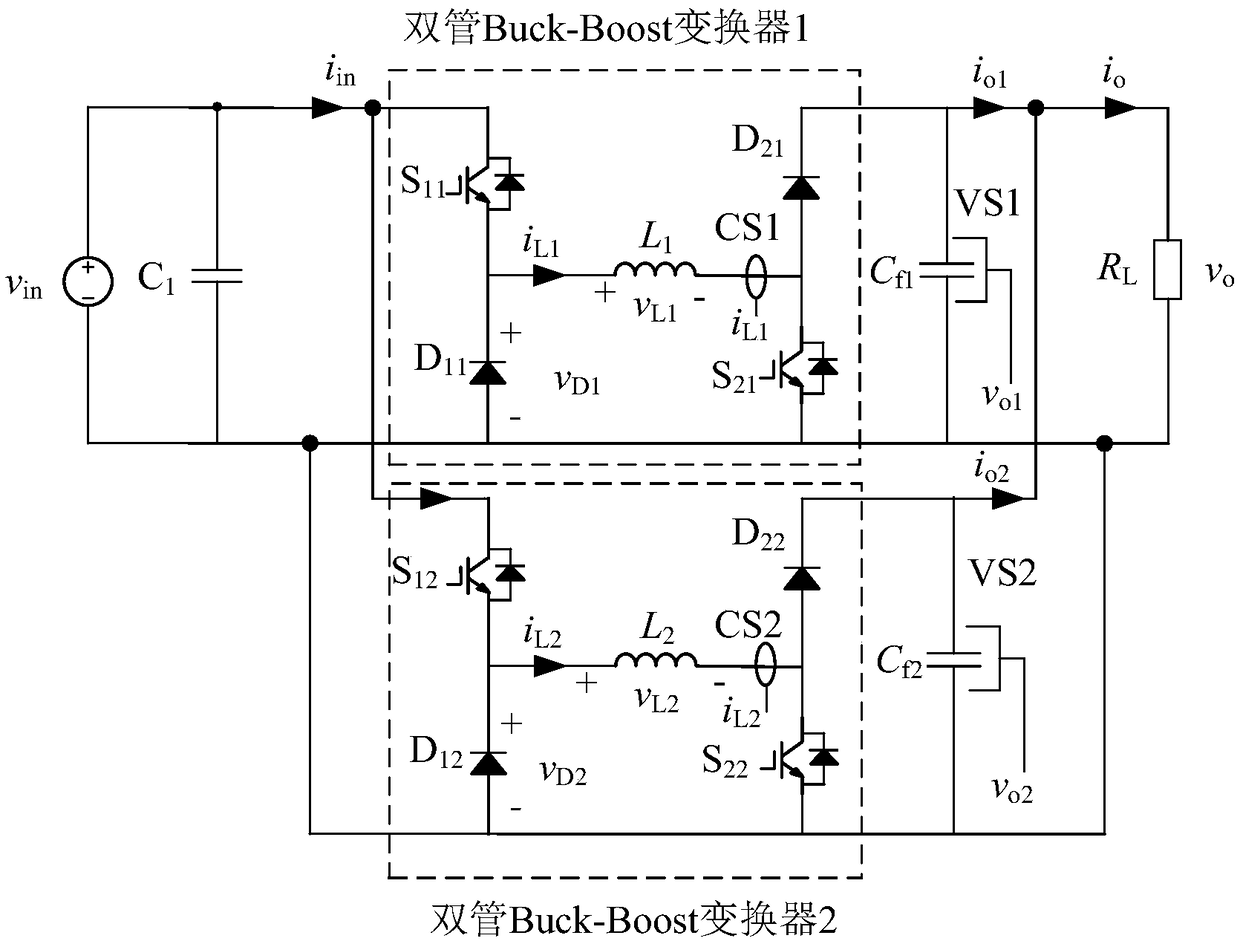

[0046] figure 2 It is a schematic diagram of parallel connection of two double-tube Buck-Boost converters used for example in the present invention;

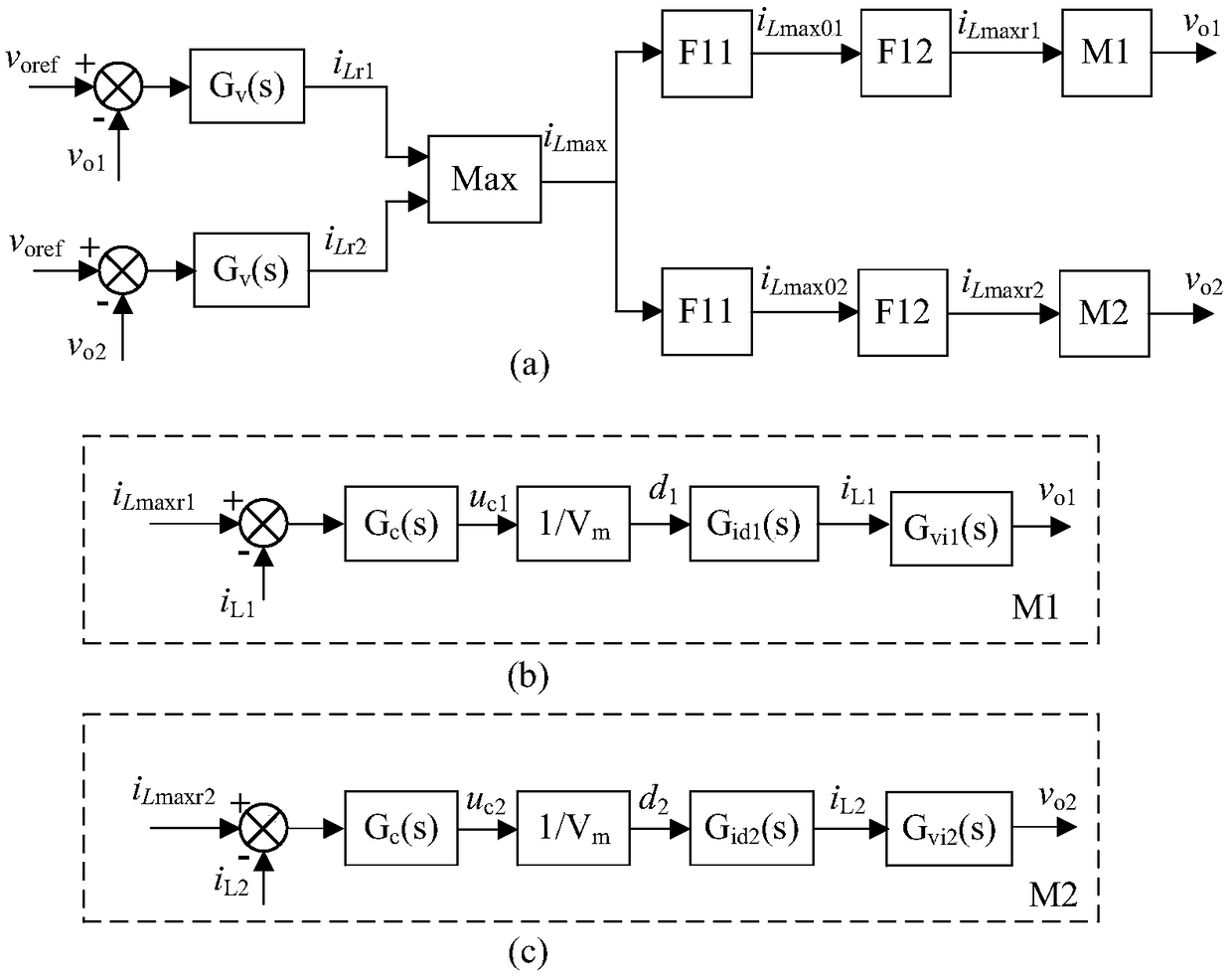

[0047] image 3 It is a schematic diagram of the control structure of the method for controlling the maximum inductor current sharing in the present invention.

[0048] Technical scheme of the present invention is realized like this:

[0049] figure 2 In , two dual-tube Buck-Boost converters are connected in parallel at the input and output. The dual-tube Buck-Boost converter itself is a mature circuit structure, so it will not be repeated here. In the figure, CS1 and CS2 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com