Adhesive films for multilayer printed wiring boards

A technology of resin film and interlayer insulating layer, applied in multilayer circuit manufacturing, printed circuit components, circuit substrate materials, etc., can solve problems such as inappropriateness, achieve high heat resistance, high insulation reliability, and excellent operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

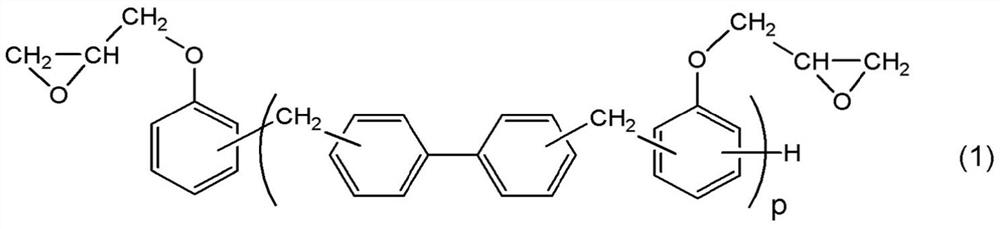

[0441] As the epoxy resin, 25.8 parts by mass of "NC-3000-H" (manufactured by Nippon Kayaku Co., Ltd., trade name, solid content concentration 100% by mass) which is a biphenyl novolac epoxy resin was blended,

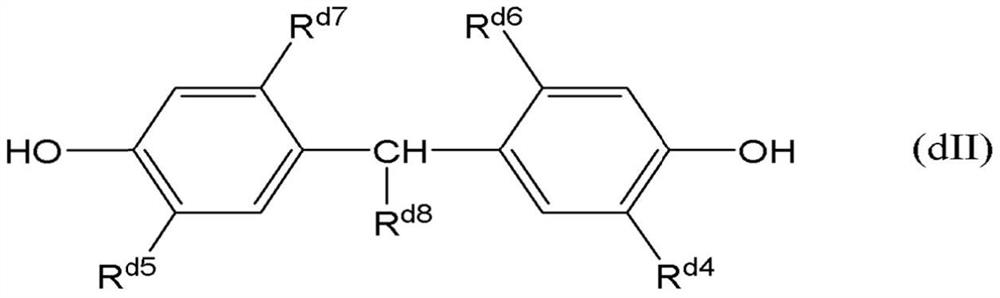

[0442] As a novolak type phenolic resin, 6.3 parts by mass of "PAPS-PN2" (manufactured by Asahi Organic Materials Co., Ltd., trade name, solid content concentration 100% by mass, Mw / Mn=1.17) was blended,

[0443] As an epoxy resin curing agent, 4.9 parts by mass of "LA-1356-60M" (manufactured by DIC Corporation, trade name, solvent: MEK, solid content concentration 60% by mass) as a triazine-modified phenol novolak resin was blended,

[0444] As an inorganic filler, the surface of "SO-C2" (manufactured by Admatechs Co., Ltd., trade name, average particle size; 0.5 μm) is treated with an aminosilane coupling agent, and further dispersed in MEK. 92.9 parts by mass of silicon (solid content concentration 70% by mass),

[0445] As a curing accelerator, 0.026 parts by mass...

Embodiment 2~6、8

[0448] Embodiment 2~6, 8, comparative example 1~4

[0449] In Example 1, except having changed the raw material composition and manufacturing conditions as described in Table 1, it carried out similarly to Example 1, and obtained the adhesive films 2-6, 8-12.

Embodiment 7

[0451] Preparation Resin varnish A prepared in the following steps is applied on PET (manufactured by Teijin DuPont Film Co., Ltd., trade name: G2, film thickness: 50 μm) as a support film so that the film thickness is 10 μm, and dried. A 60 μm thick support film 2 .

[0452] The resin varnish A used above was produced in the following procedure.

[0453] As the epoxy resin, 63.9 parts by mass of "NC-3000-H" (manufactured by Nippon Kayaku Co., Ltd., trade name, solid content concentration 100% by mass) which is a biphenyl novolac epoxy resin was blended,

[0454] As an epoxy resin curing agent, 18.0 parts by mass of "LA-1356-60M" (manufactured by DIC Corporation, trade name, solvent; MEK, solid content concentration 60% by mass) as a triazine-modified phenol novolak resin was blended,

[0455] Blending 15.2 parts by mass of "EXL-2655" (manufactured by Rohm and Haas Electronic Materials Co., Ltd., trade name) as core-shell rubber particles,

[0456] As an inorganic filler, 8....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com