Vanadium corrosion inhibitors in gas turbine applications

A corrosion inhibitor, gas turbine technology, applied in gas turbine installations, fuel additives, fuels, etc., can solve problems such as low economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0031] For an easier understanding of the embodiments, reference is made to the following examples, which are intended to illustrate the embodiments disclosed and described in this application. These examples in no way limit the scope.

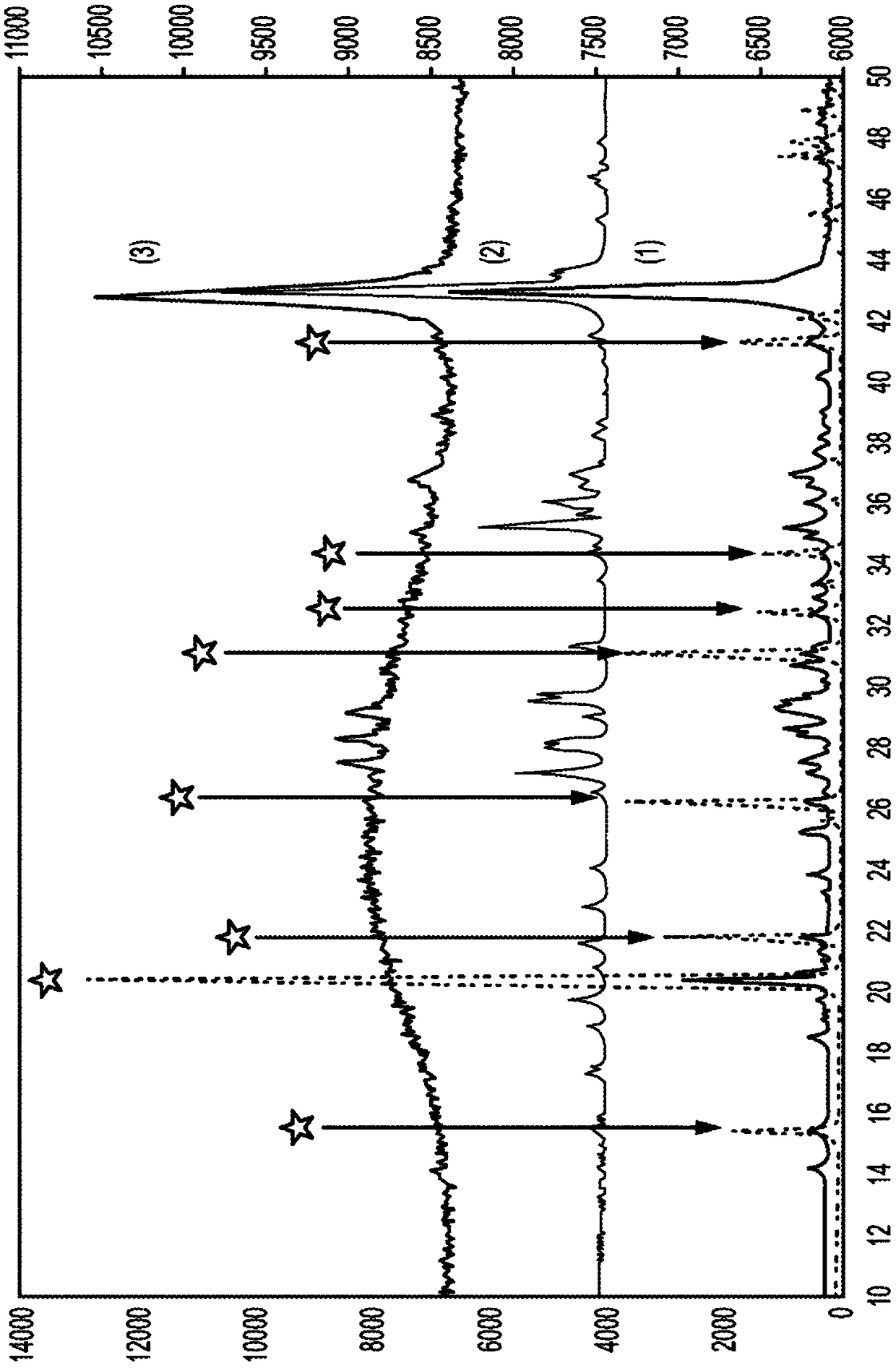

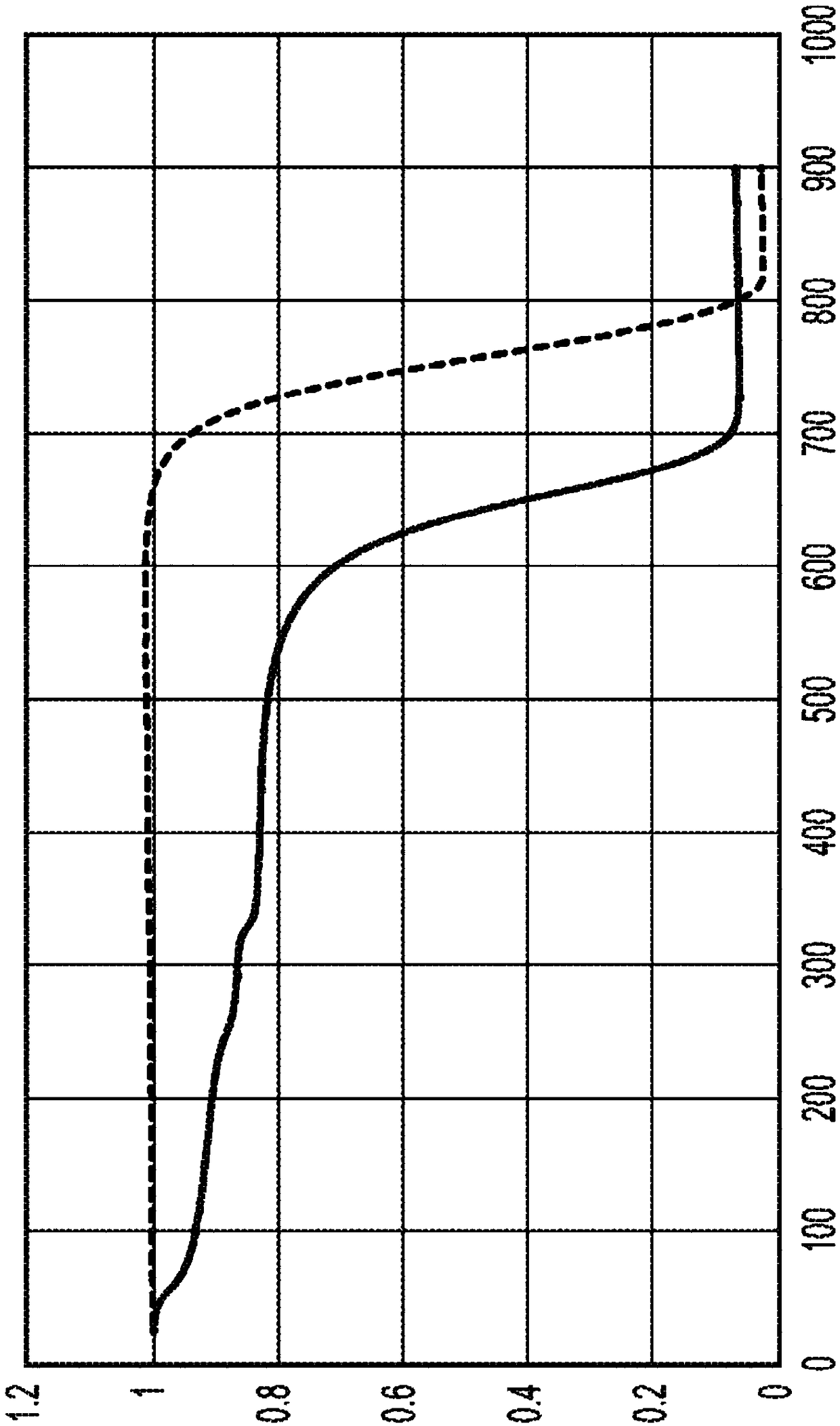

[0032] Carbon black was pretreated with the following procedure: obtained from Denka and having a particle size of 35nm, 68m 2 Acetylene black with a surface area of / g and an ash content of 0.01 weight percent was soaked in nitric acid (2 standard values (N)) for 24 hours at room temperature. Then, filter the carbon black and blow it with flowing nitrogen (N 2 ) was dried at 250°C. The dried carbon black was added to deionized water (having a conductivity of less than 0.056 microSiemens per centimeter (μS / cm); Type I water by ASTM definition) and refluxed for at least 6 hours before adding the magnesium compound. The weight ratio of carbon to water after drying is 1:2. The mixture of carbon and water, called carbon black slurry (CBS),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com