Surface modification method for polymer separation membranes

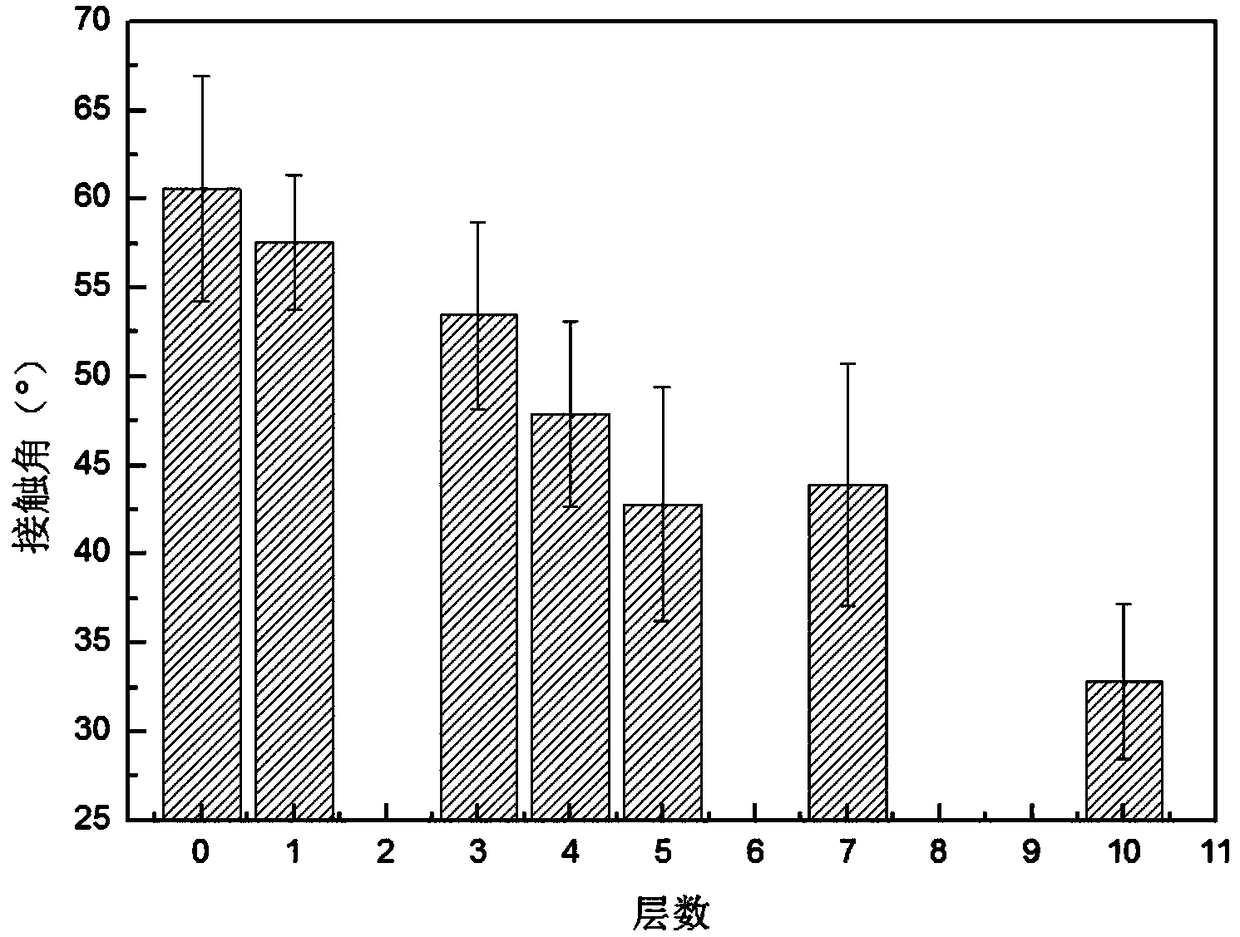

A technology of surface modification and polymer membrane, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of secondary pollution cost, poor controllability, waste of raw materials, etc., and achieve time saving and low cost , Improve the effect of hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

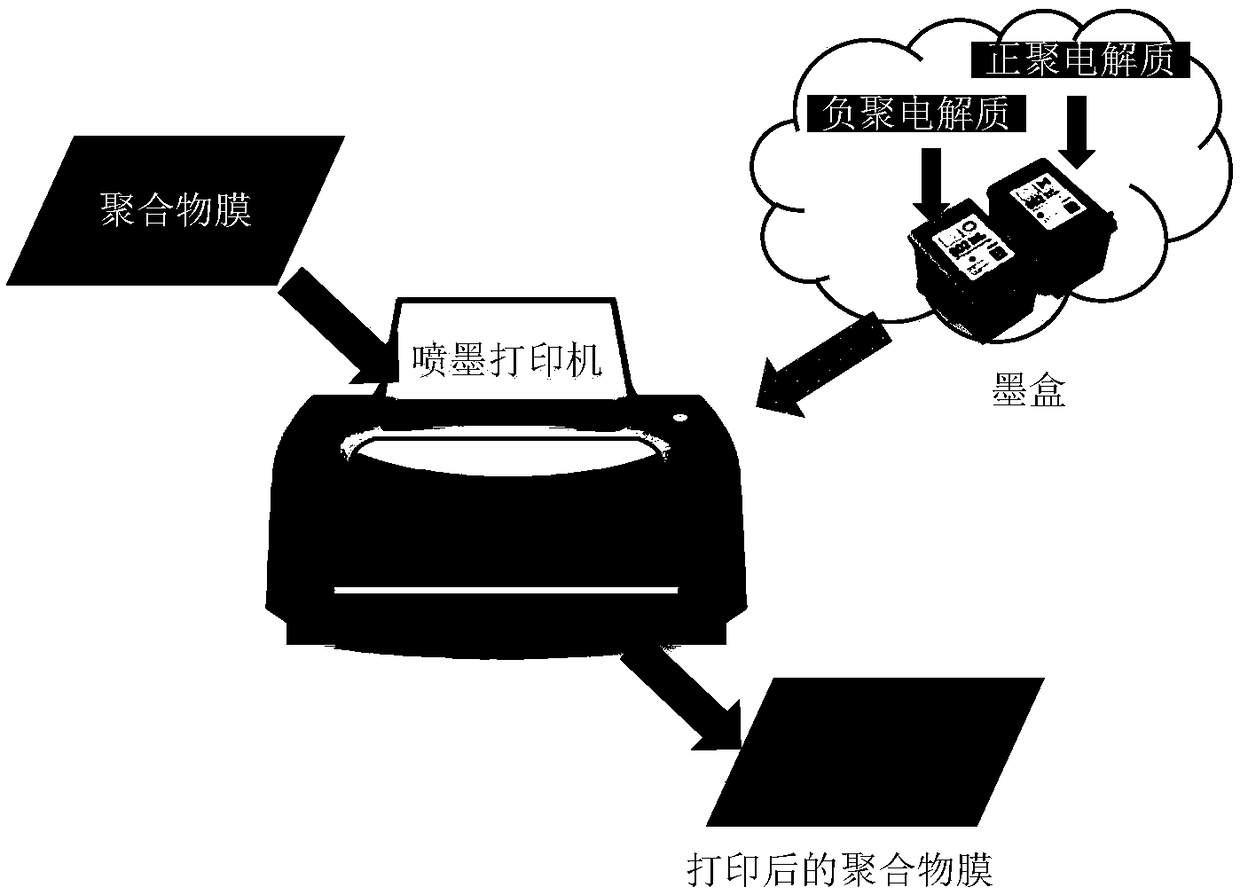

[0032] Embodiment 1 The method for polymer separation membrane surface modification

[0033] The sodium chloride (NaCl) solid of 5.844 grams is added to the deionized water of 100 milliliters, fully stirs it to dissolve with glass rod, then, adds 0.1 gram polydiallyl dimethyl ammonium chloride ( PDADMAC) to prepare a positively charged polyelectrolyte solution of 1 gram per liter, and ultrasonically sound for 10 minutes after fully stirring; also add 5.844 grams of sodium chloride (NaCl) solid to 100 ml of deionized water, and fully stir with a glass rod Allow it to dissolve, then add 0.1 g of polystyrene sodium sulfonate (PSS) to this solution to prepare a 1 g / L negatively charged polyelectrolyte solution, stir thoroughly and ultrasonically for 10 minutes; fill the empty ink cartridge Ionized water, start the cleaning program of the printer for cleaning to get a clean ink cartridge and ink supply system; then fill the black ink cartridge with positively charged polydiallyl di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com