An all-in-one machine for mbr

An all-in-one, standard-raising technology, applied in special treatment targets, multi-stage water/sewage treatment, biological water/sewage treatment, etc., can solve problems affecting sewage treatment efficiency, etc. Full cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

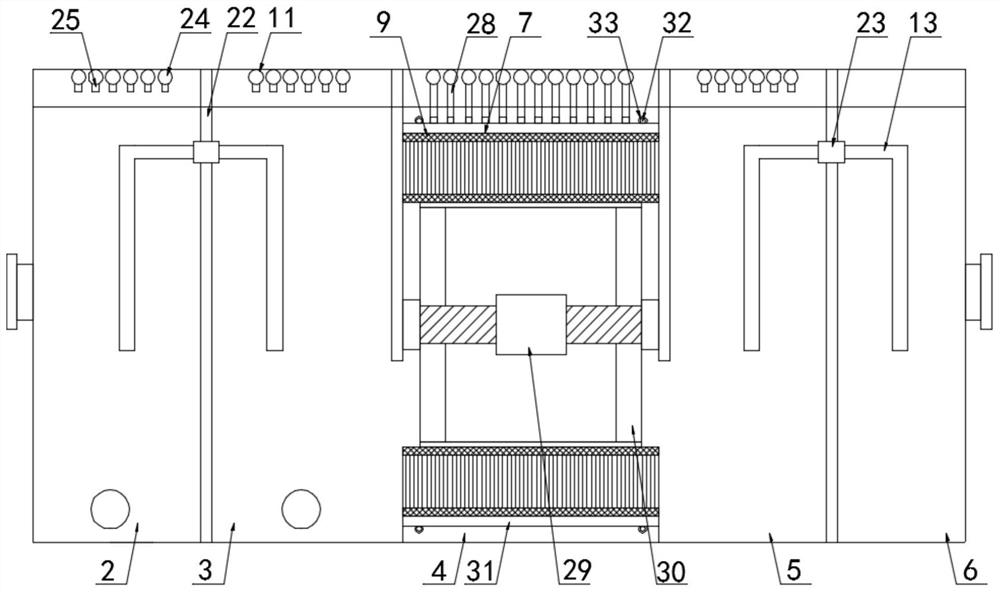

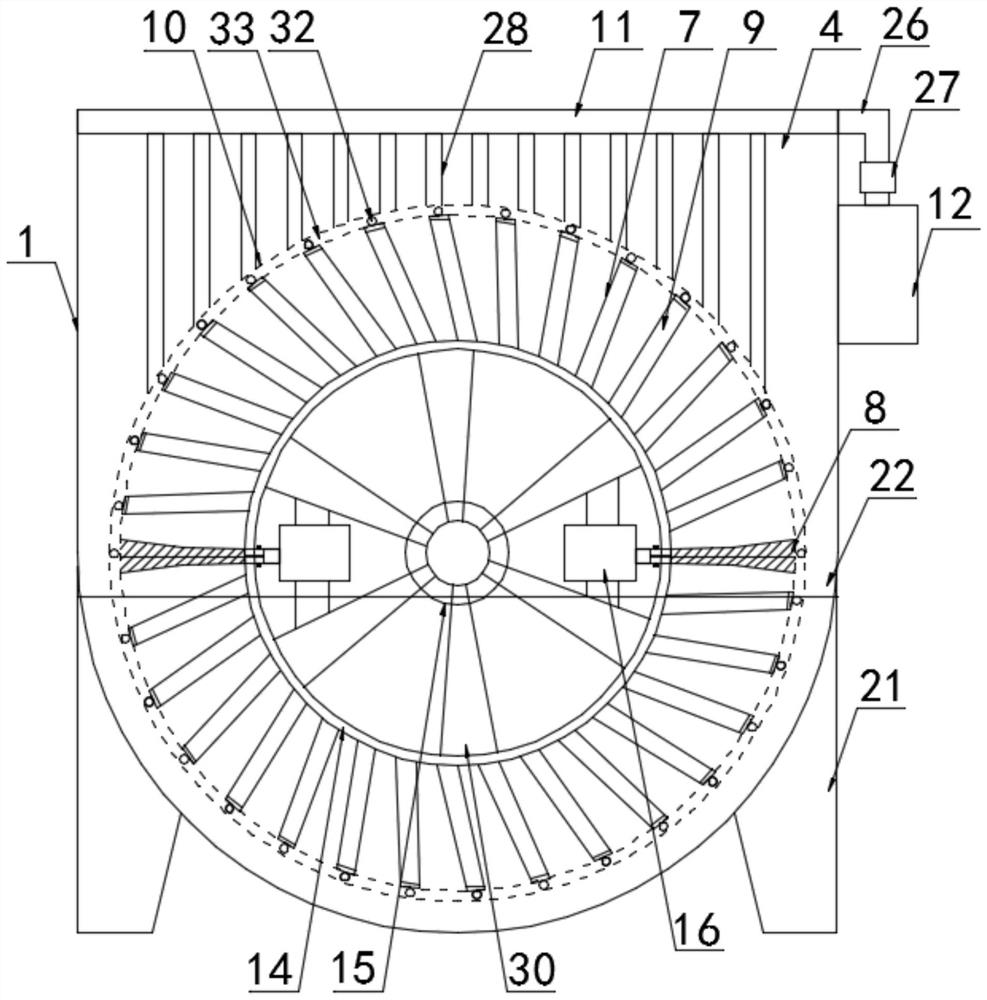

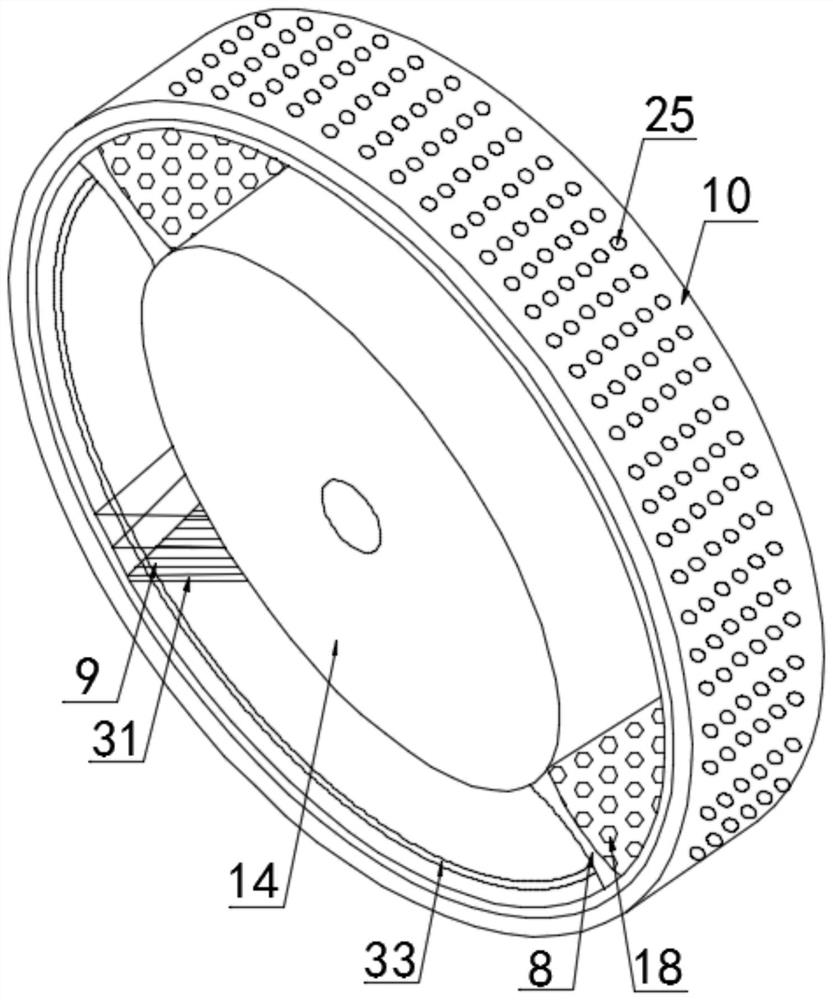

[0026] according to Figure 1-2 A kind of MBR all-in-one machine for raising standards shown includes a body 1, and the inside of the body 1 is provided with an anaerobic chamber 2, an aerobic chamber 3, a reaction chamber 4, a dosing chamber 5 and a water purification chamber 6, and the body 1 The section is U-shaped, which is convenient for the rotation of the filter mechanism 7 and the cleaning of the top feed. The bottom of the body 1 is provided with support frames 21. The anaerobic chamber 2, aerobic chamber 3, reaction chamber 4, and dosing chamber 5 A sealing partition 22 is provided between the water purification chamber 6, a liquid inlet is provided on one side of the anaerobic chamber 2, a liquid outlet is provided on one side of the water purification chamber 6, and a liquid outlet is provided on one side of the anaerobic chamber 4. The bottom of the sealing partition 22 is provided with a semicircular through hole, which is convenient for water inlet and outlet. ...

Embodiment 2

[0029] according to figure 2As shown in the MBR all-in-one machine, the feeding pipe group 11 includes a plurality of feeding pipes 24 evenly spaced, the bottom of the feeding pipe 24 is provided with a nozzle 25, and one end of the feeding pipe group 11 is connected to a main pipe 26 , the main pipe 26 is connected with the feeding tank 12, the main pipe 26 is provided with a pressure pump 27, and a long pipe 28 is arranged between the bottom of the corresponding feeding pipe 24 in the reaction chamber 4 and the nozzle 25, and the long pipe 28 Extending to the inside of the outer sealing ring plate 10 and the nozzle 25 is arranged on the inner side of the outer sealing ring plate 10, which is convenient for spraying sodium hypochlorite solution to the inner MBR membrane group 9, so that the MBR membrane group 9 is cleaned, and avoids long-term use without effective cleaning Affect the filtering effect, so that the sewage treatment is not up to standard, the drive mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com