PROCESS FOR PREPARING SiC-BONDED POLYETHERSILOXANES

A technology of polyether siloxane and siloxane, applied in the field of organopolysiloxane, can solve the problems of no practical significance of cost, no practical significance of quality defects, no mention of product characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Example 1 (non-inventive):

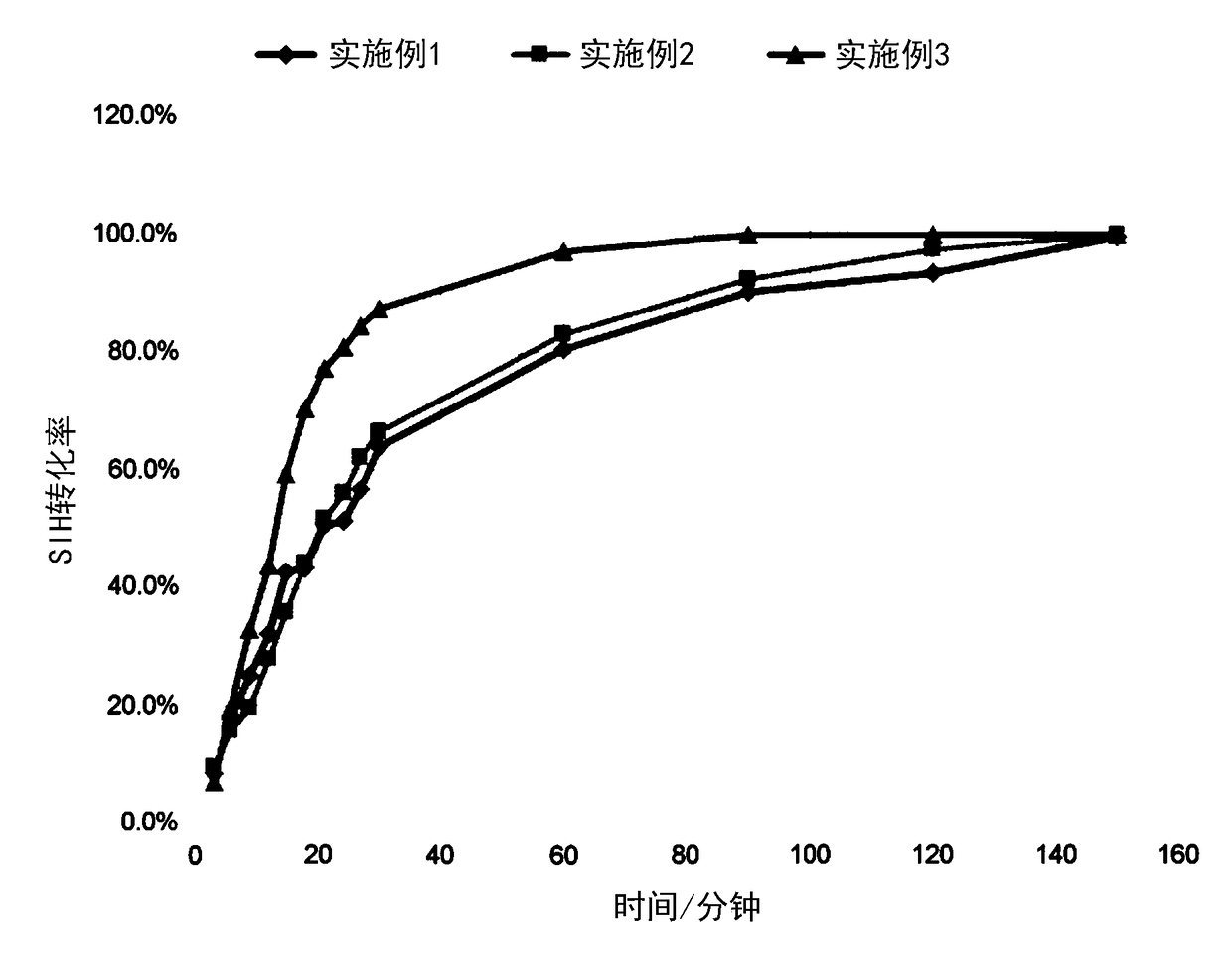

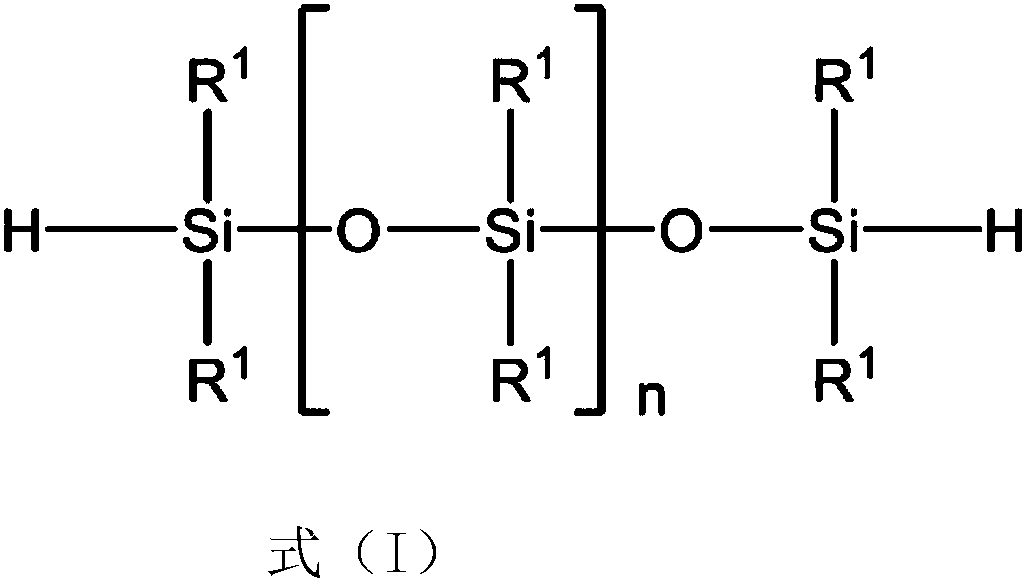

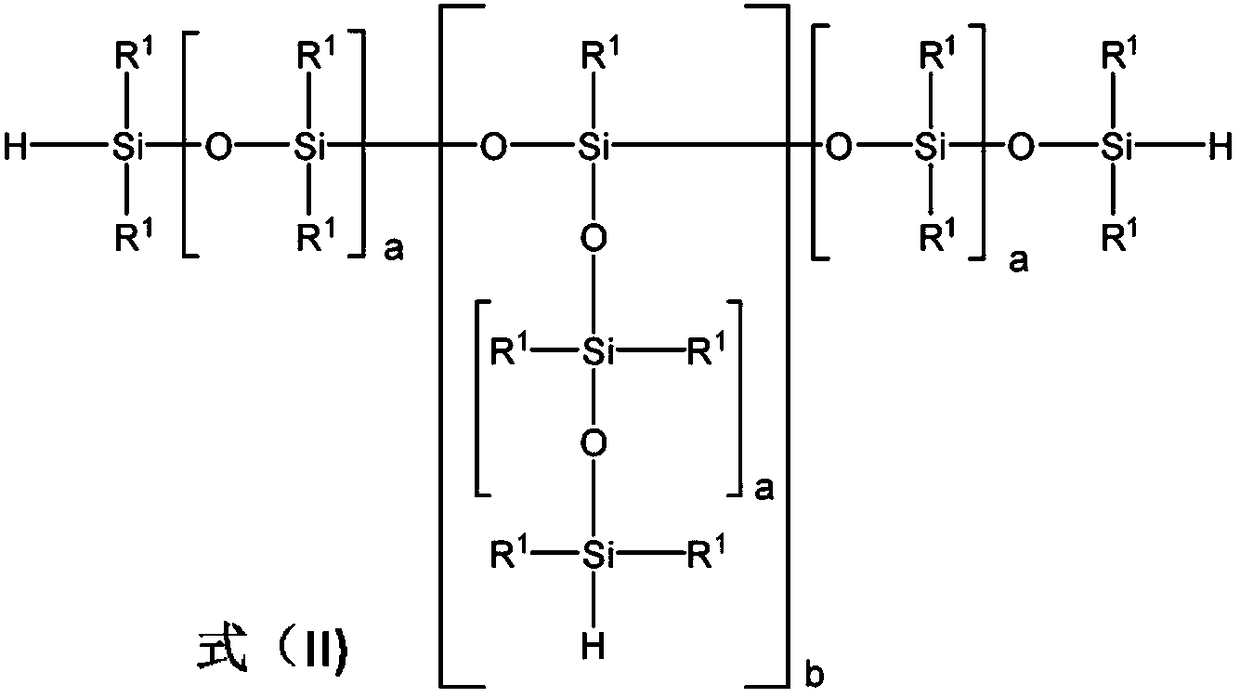

[0101] First add 30.8g (75mmol) of poly(methylhydrogen)polydimethylsiloxane to a 250ml three-necked flask equipped with a contact thermometer, a precision glass stirrer and a reflux condenser, and its gas volume method records SiH value 2.44 eq / kg, and 87.4 g (101.5 mmol) of allyl alcohol-started ethylene oxide / propylene oxide based polyether (propylene oxide content 26% by weight) with an iodine value of 30.5 g / 100 g, heated to 70°C in 7 minutes by a heating mantle under stirring (400 rpm). The reaction was started by adding 5 ppmw of platinum in the form of an ethylene-activated Karstedt catalyst according to EP 1 520 870 B1 dissolved in decamethylcyclopentasiloxane. To check the conversion of the exothermic reaction, samples were taken every 3 minutes during the first 30 minutes and weighed in the decomposition flask. The respective SiH conversions were then determined by the volumetric method in a burette by decomposition of the weighe...

Embodiment 2

[0102] Embodiment 2 (non-inventive):

[0103] In the 250ml three-necked flask that is equipped with contact thermometer, precise glass stirrer and reflux condenser, first add the polyether siloxane prepared in the embodiment 1 of 6.2g (5wt%, based on whole mixture), and 87.4g ( 101.5 mmol) of an allyl alcohol-initiated ethylene oxide / propylene oxide based polyether (propylene oxide content 26% by weight) with an iodine number of 30.5 g / 100 g was heated under stirring (400 rpm) The jacket was heated to 70°C within 7 minutes. By immediately adding 30.8g (75mmol) of poly(methylhydrogen)polydimethylsiloxane, which had a SiH value of 2.44eq / kg by gas volumetric method, and 5ppmw dissolved in decamethylcyclopentasiloxane Platinum in alkanes in the form of an ethylene-activated Karstedt catalyst according to EP 1520 870 B1 starts the reaction. To check the conversion of the exothermic reaction, samples were taken every 3 minutes during the first 30 minutes and weighed in the decomp...

Embodiment 3

[0104] Embodiment 3 (of the present invention):

[0105] In the 250ml three-neck flask that is equipped with contact thermometer, precision glass stirrer and reflux condenser, first add the polyether siloxane prepared in the embodiment 1 of 6.2g (based on 5% of total mixture) and 30.8g (75mmol ) of poly(methylhydrogen)polydimethylsiloxane, whose SiH value measured by the gas volume method is 2.44eq / kg hydrogen siloxane, is heated to within 7 minutes by a heating mantle under stirring (400rpm) 70°C. An ethylene oxide / propylene oxide based polyether (propylene oxide content 26% by weight) started by immediate addition of 87.4 g (101.5 mmol) of allyl alcohol with an average molar mass of 843 g / mol and 5 ppmw Platinum in the form of an ethylene-activated Karstedt catalyst according to EP 1520870 B1 dissolved in decamethylcyclopentasiloxane starts the reaction. To check the conversion of the exothermic reaction, samples were taken every 3 minutes during the first 30 minutes and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com