Environmental protection construction method of expressway

A construction method and highway technology, applied in the directions of roads, roads, side ditch/curb stones, etc., can solve the problems of easy icing on the surface, affecting the service life of the road, and easy cracking of the road, so as to improve the operation stability and use. Longevity, preventing freeze-thaw damage to roadbed, and excellent comprehensive performance of highways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

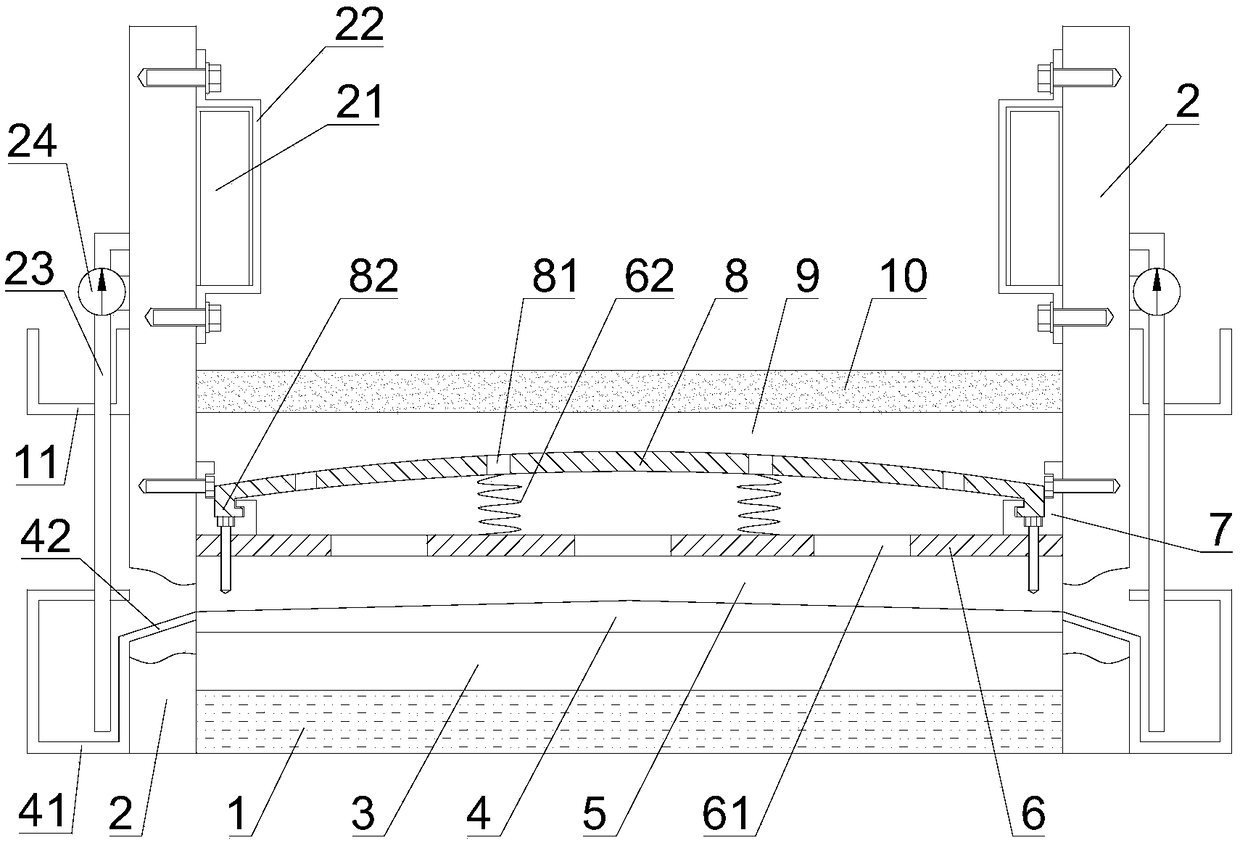

[0042] Such as figure 1 As shown, the expressway environmental protection construction method that the present embodiment provides, comprises the following steps:

[0043] S1: use a road roller to roll the soil base 1, compact the soil base 1, so that the compaction degree of the soil base 1 is ≥ 95%;

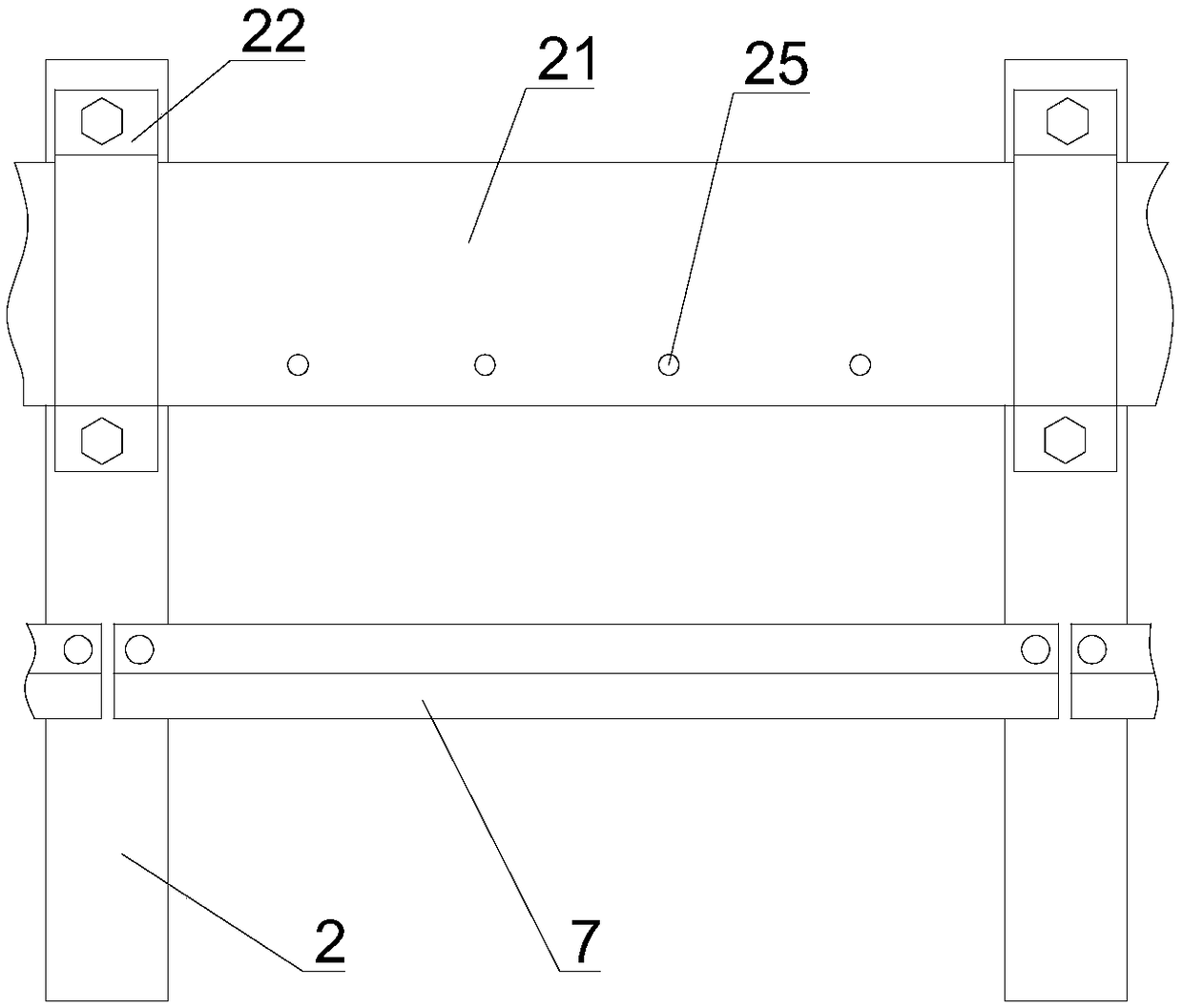

[0044] S2: setting multiple support piles 2 on both sides of the soil base 1, the support piles 2 are steel support piles, and the depth of the support piles 2 driven into the soil base 1 is ≥ 50cm;

[0045] S3: Lay the base cushion 3 on the soil base 1, the material composition and mass ratio of the base cushion 3 are: 45-50% coarse gravel, 25-30% fine gravel, 15-20% silicate Cement, 4-8% water, the size of the coarse gravel is 7cm-11cm, and the size of the fine gravel is 3cm-5cm. After using a concrete mixer to fully mix 45-50% coarse gravel, 25-30% fine gravel, 15-20% Portland cement, and 4-8% water, it is laid on the soil base 1, and the base cushion 3. The material rati...

Embodiment 2

[0061] The difference between this embodiment and Embodiment 1 is that the step S2 of the expressway environmental protection construction method is: drilling and pouring a plurality of support piles 2 on both sides of the soil base 1, and pouring the support piles 2 into the soil base 1 Depth ≥ 50cm. Others are the same as in Example 1.

Embodiment 3

[0062] The further antiskid environmental protection improvement of embodiment 3 superhydrophobic mixed solution:

[0063] Ammonia water is also called ammonia water, the main component is NH 3 ·H 2 O, is an aqueous solution of ammonia, colorless and transparent with a pungent odor. Ammonia has a melting point of -77°C, a boiling point of 36°C, and a density of 0.91g / cm3. Ammonia is easily soluble in water and ethanol. It is volatile and has some alkaline properties. Ammonia water is produced by passing ammonia gas into water. Ammonia is poisonous, irritating and corrosive to eyes, nose and skin, and can suffocate people. The maximum allowable concentration in the air is 30mg / m 3 . It is not good for the environment and worker safety.

[0064] In recent years, traffic safety issues have gradually attracted the attention of all walks of life, and how to improve the anti-slip performance of asphalt pavement in rainy weather has become the focus of current research.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com