An operation method of a full-diameter spanning perforation-testing joint string

An operation method and full-bore technology, which is applied in the field of oil and gas well testing, can solve the problems of difficult real-time recording of test valves across perforation, less pipe string functions, and difficulty in rod fishing, so as to solve the problem of wellbore storage effect, Reduce the number of operations and the probability of reservoir contamination, and avoid the effect of salvaging and throwing rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

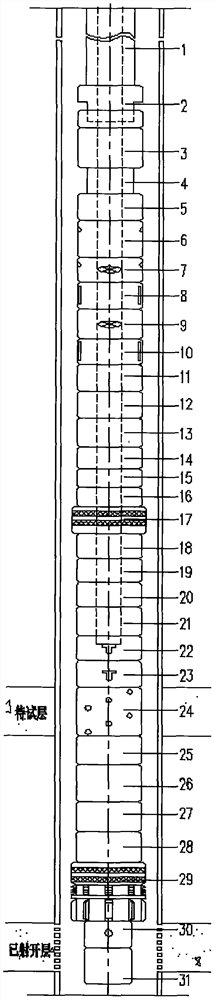

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

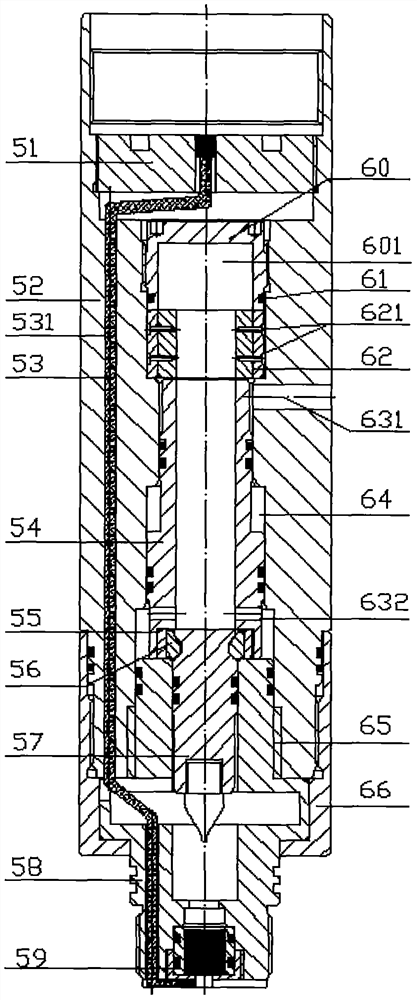

[0033] Such as figure 2 As shown, the parallel detonation type pressure delay ignition head 23 includes: detonating cord frame 51, upper joint 52, detonating cord 53, detonating cord hole 531, sliding sleeve 54, locking block cover 55, locking block 56, firing pin Assembly 57, spline joint 58, delay detonator assembly 59, plug 60, hollow cavity 601, seal ring 61, shear assembly 62, shear pin 621, pressure transmission hole 1 631, pressure transmission hole 2 632 , Air cavity 64, spline 65, jacket joint 66.

[0034] The inner side of the upper joint 52 is sequentially provided with a detonating cable holder 51, a plug 60, a shear assembly 62, a sliding sleeve 54, a lock block sleeve 55 and a lock block 56, and the outer wall of the upper joint 52 is radially provided with A pressure transmission hole 631 is provided with a detonating cord hole 531 in the axial direction, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com