Pre-supercharge active air inlet, air exhaust and exchanging exhaust type engine

An engine and exhaust type technology, which is applied in the direction of engine control, combustion engine, machine/engine, etc., can solve the problems of waste of fuel, large engine pollution, etc., and achieve the effect of enhanced heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

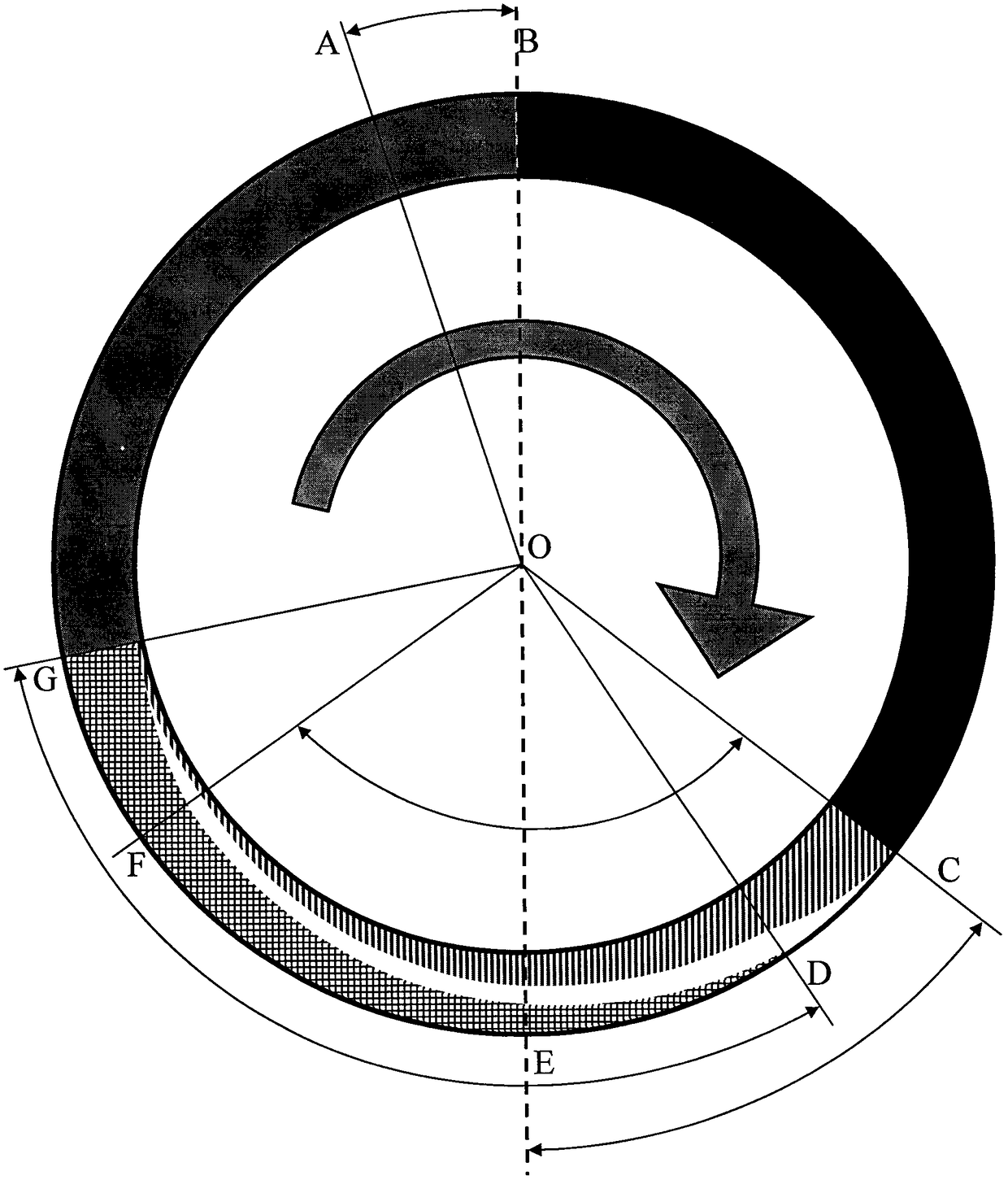

[0019] On the basis of the existing ordinary four-stroke engine, a full-range supercharging system is added, which is composed of a supercharging compressor, a radiator, and a sensor. There are three specific implementations of the booster part: 1. A separate mechanical booster compressor, which has the disadvantage of wasting more energy; 2. The mechanical booster compressor and the exhaust gas turbocharger are used at the same time. Under the control of the control system ECU, the low speed is mainly operated by the supercharger compressor. At high speed, the supercharger compressor makes up for the lack of boosting capacity of the exhaust gas turbocharger compressor; 3. Combine the supercharger compressor with the exhaust gas turbocharger. The compression compressor is integrated, specifically adding a high-speed motor to the exhaust gas turbocharger compressor, and increasing the volume of the turbocharger. Under the control of the sensor and the electronic control system E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com