A microfocal X-ray tube based on field emission of carbon nanotubes

An X-ray tube, carbon nanotube technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

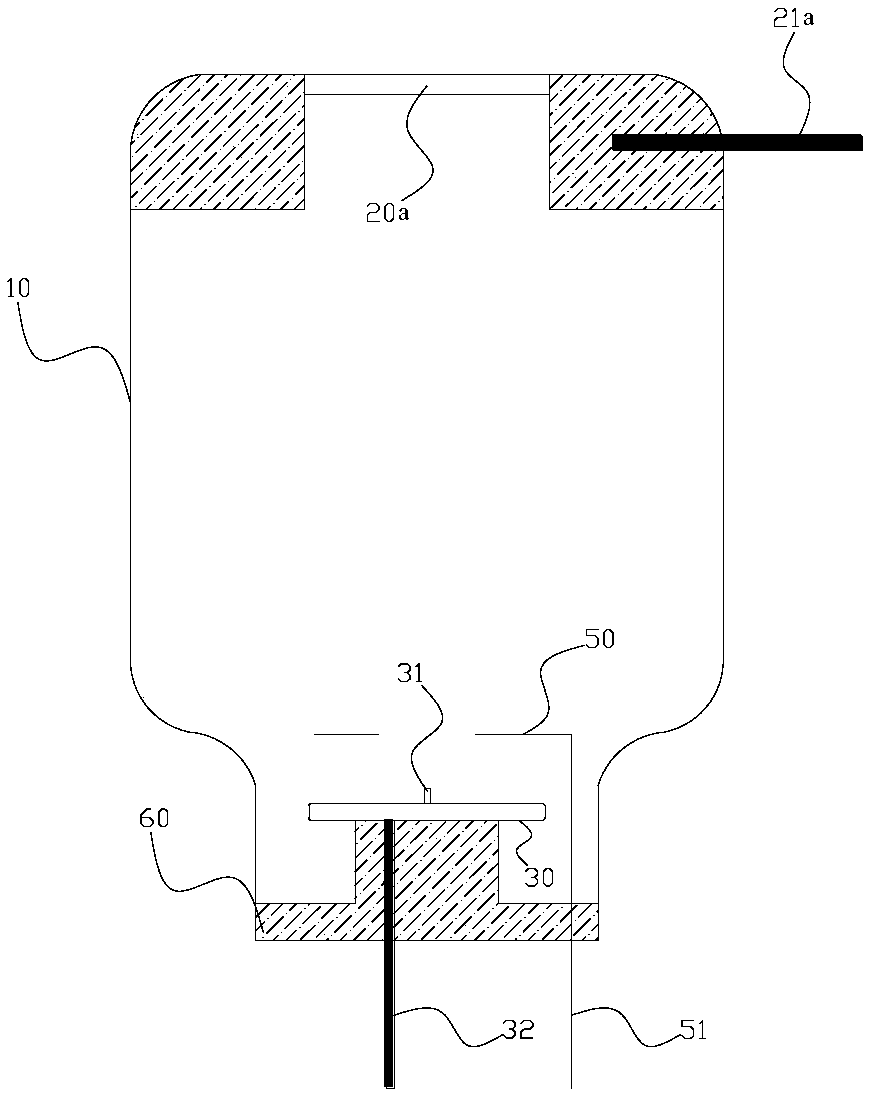

[0053] Embodiment one adopts figure 1 Described end window structure. Please refer to figure 1 As shown, a micro-focus X-ray tube based on carbon nanotube field emission includes a vacuum vessel 10 and an anode target 20a installed in the vacuum vessel 10 and an electron gun, and the electron gun includes an emission cathode and a control grid 50, The emission cathode and the anode target 20a are respectively installed at opposite ends of the vacuum vessel 10, the control grid 50 is installed between the emission cathode and the anode target 20a, and the emission cathode includes the emission cathode substrate 30 and is vertically grown on The carbon nanotube microbundle 31 extending toward the anode target 20a on the emission cathode substrate 30, the carbon nanotube microbundle 31 is a single bundle of carbon nanotubes or a carbon nanotube array with a diameter of 0.1-500 μm, that is, if it is For a single bundle of carbon nanotubes, the diameter of the single bundle of ca...

Embodiment 2

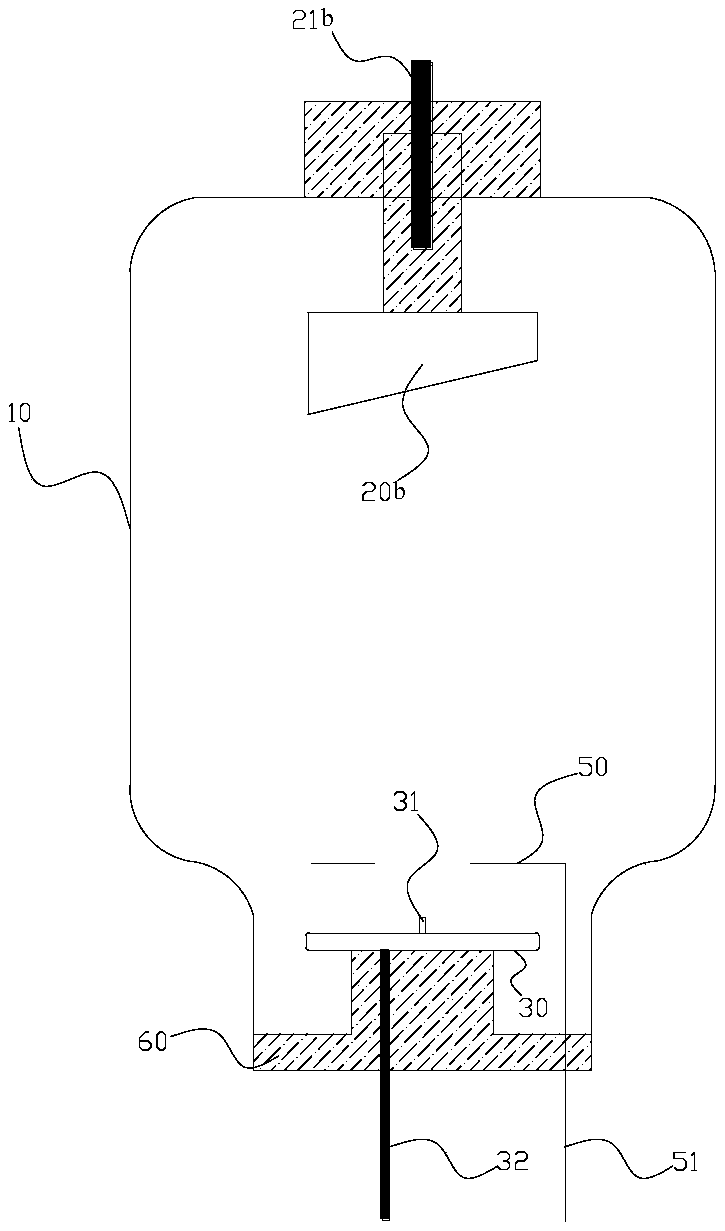

[0069] The difference between the second embodiment and the first embodiment is that the installation position of the anode target 20b is different. The first embodiment adopts the end window structure, while the second embodiment adopts the side window structure. Please refer to figure 2 As shown, a micro-focus X-ray tube based on carbon nanotube field emission includes a vacuum vessel 10 and an anode target 20b installed in the vacuum vessel 10 and an electron gun, and the electron gun includes an emission cathode and a control grid 50, The emission cathode and the anode target 20b are respectively installed at opposite ends of the vacuum container 10, the control grid 50 is installed between the emission cathode and the anode target 20b, and the emission cathode includes the emission cathode substrate 30 and is vertically grown on The emitting carbon nanotube microbundle 31 on the cathode substrate 30 and extending toward the anode target 20b, the carbon nanotube microbund...

Embodiment 3

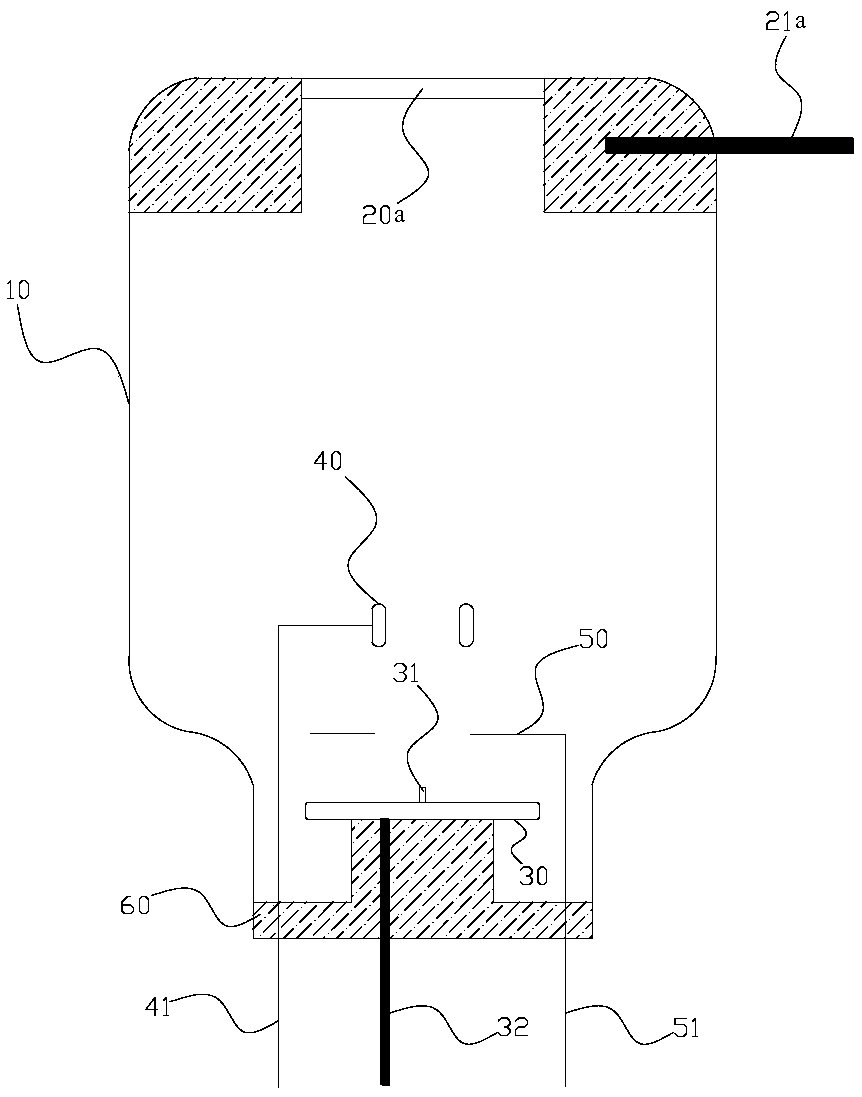

[0072] Embodiment three adopts image 3 Described X-ray tube end window structure. Please refer to image 3 As shown, a micro-focus X-ray tube based on carbon nanotube field emission includes a vacuum vessel and an anode target 20a installed in the vacuum vessel 10 and an electron gun, and the electron gun includes an emission cathode and a control grid 50, so The emitting cathode and the anode target 20a are respectively installed at opposite ends of the vacuum container 10, the control grid 50 is installed between the emitting cathode and the anode target 20a, and the emitting cathode includes the emitting cathode substrate 30 and is vertically grown on the The carbon nanotube microbundle 31 that is emitted on the cathode substrate 30 and extends toward the anode target 20a, the carbon nanotube microbundle 31 is a single bundle of carbon nanotubes or a carbon nanotube array with a diameter of 0.1-500 μm, that is, if it is a single If it is a bundle of carbon nanotubes, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com