Aromatic coconut powder and preparation method thereof

A technology of coconut powder and strong fragrance, which is applied in the preparation of coconut powder, strong fragrance coconut powder and its preparation field, which can solve the problems of coconut powder losing the fresh taste of freshly squeezed coconut milk and inferior flavor, and achieve the purpose of inhibiting growth, reproduction and taste Pure, coconut-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

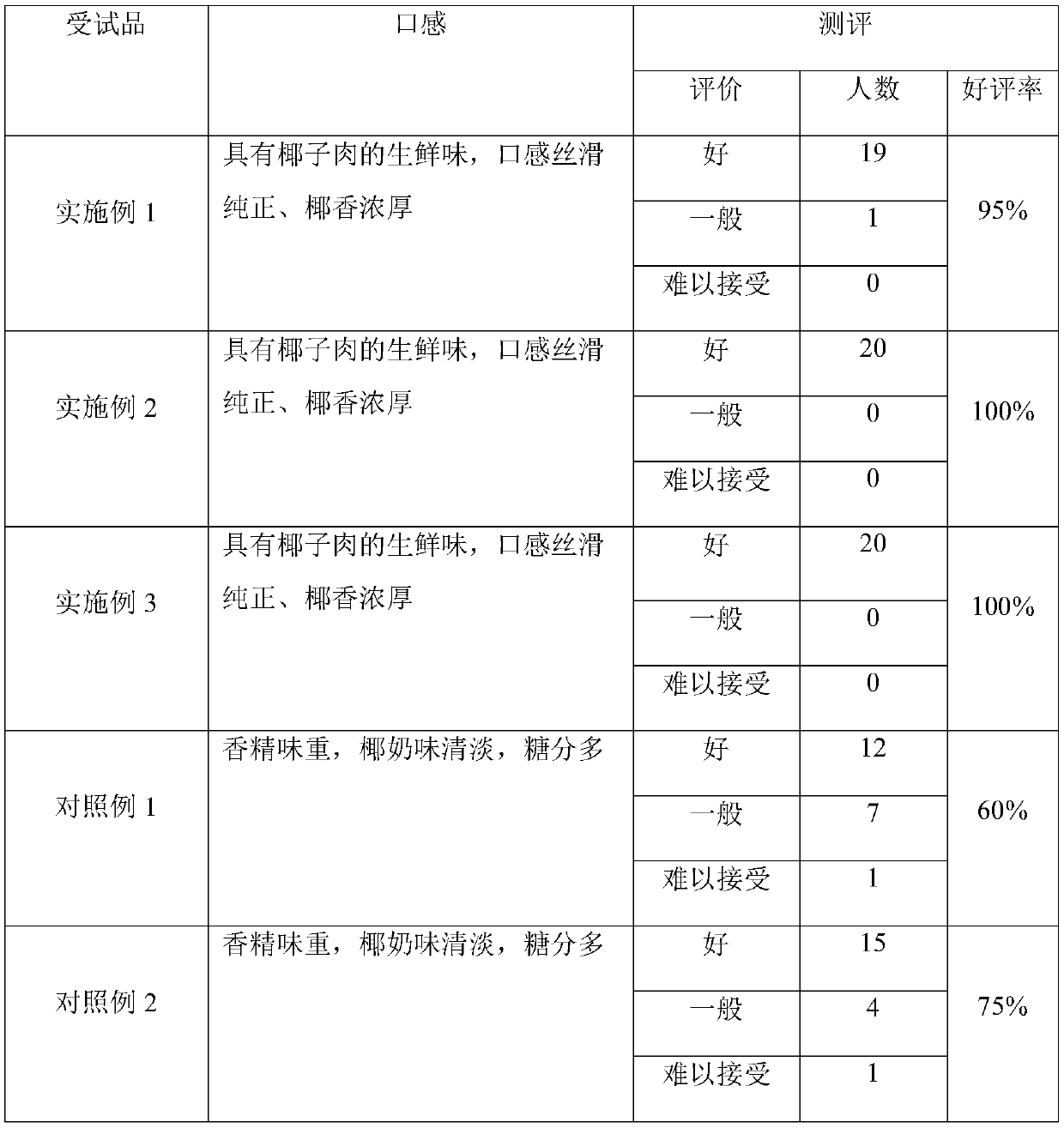

Examples

Embodiment 1

[0027] The fragrant coconut powder of the present invention is prepared from the following raw materials in parts by weight: 50 parts of fine coconut milk, 30 parts of coconut meat slag powder, 0.2 part of mogroside, 8 parts of non-dairy creamer, 5 parts of maltodextrin, cheese 1 part protein, 20 parts soft water.

[0028] The preparation method of described fragrant coconut flour, comprises the following steps:

[0029] (1) Pick the coconut meat from the Xiangshui old coconut after shelling, remove the moldy, rancid and black-skinned coconut meat, and clean it;

[0030] (2) Soak the cleaned coconut meat in a clear water tank, remove and drain, and evenly blanch the outer surface of the coconut meat with hot water at a temperature of 70°C for 1 minute. After cooling, carry out planing and pressing, and repeat the pressing for 3 times , No water is added in the first pressing, screw dry pressing is used, the slag filtered in the first pressing is continued to be screw dry pres...

Embodiment 2

[0041] The fragrant coconut powder of the present invention is prepared from the following raw materials in parts by weight: 55 parts of fine coconut milk, 35 parts of coconut dregs powder, 0.5 part of mogroside, 10 parts of non-dairy creamer, 8 parts of maltodextrin, cheese 2 parts protein, 25 parts soft water.

[0042] The preparation method of described fragrant coconut flour, comprises the following steps:

[0043] (1) After shelling the Xiangshui old coconut, take the coconut meat and pick it, remove the moldy, rancid and black-skinned coconut meat, and clean it;

[0044] (2) Soak the cleaned coconut meat in a clear water tank, remove and drain, and evenly blanch the outer surface of the coconut meat with hot water at a temperature of 85°C for 1 minute. After cooling, carry out planing and pressing, and repeat the pressing for 3 times , No water is added in the first pressing, screw dry pressing is used, the slag filtered in the first pressing is continued to be screw dr...

Embodiment 3

[0055] The fragrant coconut powder of the present invention is prepared from the following raw materials in parts by weight: 65 parts of fine coconut milk, 40 parts of coconut dregs powder, 1 part of mogroside, 15 parts of non-dairy creamer, 10 parts of maltodextrin, cheese 5 parts protein, 30 parts soft water.

[0056] The preparation method of described fragrant coconut flour, comprises the following steps:

[0057] (1) After shelling the Xiangshui old coconut, take the coconut meat and pick it, remove the moldy, rancid and black-skinned coconut meat, and clean it;

[0058] (2) Soak the cleaned coconut meat in a clear water tank, remove and drain, and evenly blanch the outer surface of the coconut meat with hot water at a temperature of 90°C for 2 minutes. , No water is added in the first pressing, screw dry pressing is used, and hot water at a temperature of 85°C is added to the slag after the first pressing and filtered in the second time, and hydraulic pressing is used, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com