Carbon loaded palladium oxide nano cluster catalyst as well as preparation method and application thereof

A technology of nano-clusters and palladium oxide, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Low catalyst activity and other problems, achieve excellent activity and stability, promote catalytic performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of carbon-supported palladium oxide nano-cluster catalyst, the steps are as follows:

[0029] Step 1: At room temperature, the porous carbon is uniformly dispersed in water to obtain a first suspension;

[0030] Among them, the porous carbon is preferably activated carbon, more preferably Vulcan XC-72 type activated carbon; the porous carbon is uniformly dispersed in water by: first mixing the porous carbon and water, and then ultrasonically dispersing the porous carbon uniformly; the ratio of porous carbon and water There is no particular limitation, as long as the porous carbon can be uniformly dispersed, the preferred ratio of the porous carbon to water is (0.1-0.3 g):(100-300 mL).

[0031] Step 2, adding the Pd(II) precursor dropwise to the first suspension, stirring for 4-6 hours, so that the Pd(II) precursor is fully adsorbed on the surface of the porous carbon to obtain the second suspension;

[0032] Among them, the Pd(II) precursor is pr...

Embodiment 1

[0043] At room temperature, add 0.3 g of Vulcan XC-72 activated carbon to 300 mL of water, and sonicate to make the activated carbon dispersed evenly to obtain the first suspension; add 0.2 g of H 2 PdCl 4 Add dropwise to the first suspension, stir for 4h, make H 2 PdCl 4 Fully adsorb on the surface of activated carbon to obtain a second suspension; adjust the pH of the second suspension to 11 with NaOH solution, stir at room temperature for 8 hours to obtain a third suspension, filter the third suspension, wash with water and drying to obtain a carbon-supported palladium oxide nano-cluster catalyst.

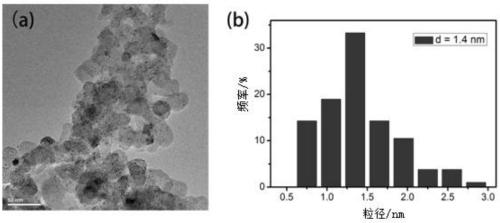

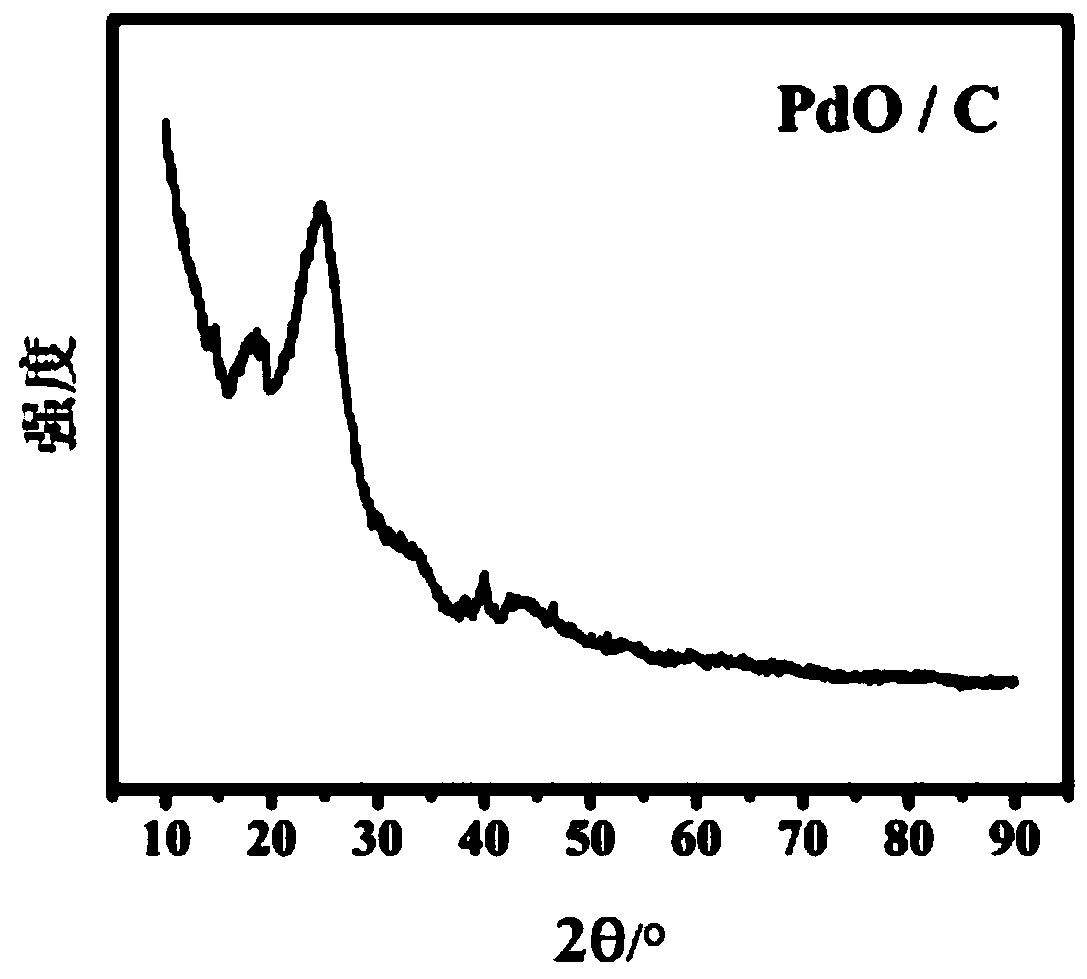

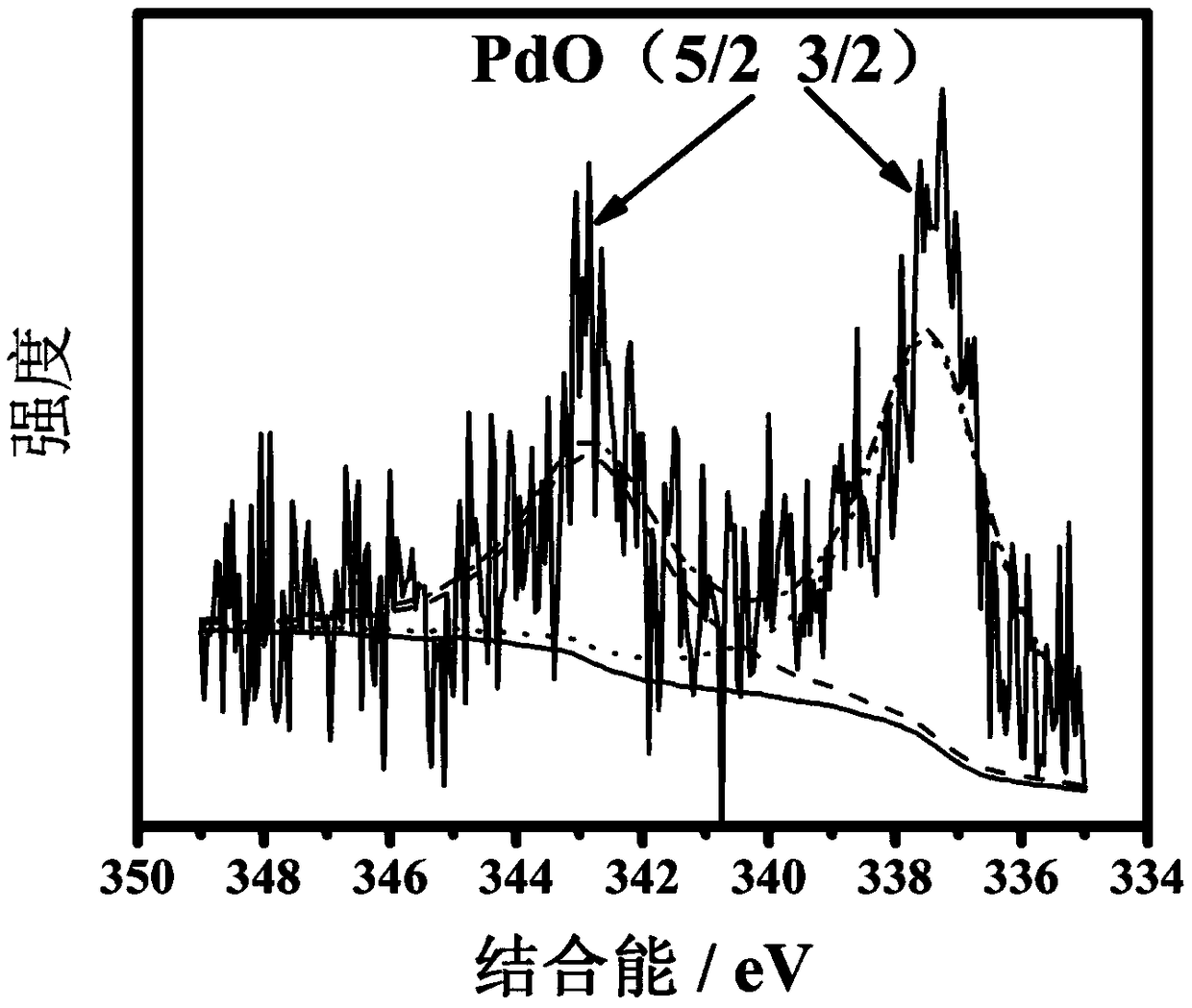

[0044] The carbon-supported palladium oxide nanocluster catalyst of Example 1 is observed by transmission electron microscope, and its particle size distribution is analyzed, and the results are as follows figure 1 shown, from figure 1 It can be seen that the palladium oxide nanoclusters of the catalyst of Example 1 are uniformly dispersed, and the particle size thereof is 0...

Embodiment 2

[0047] At room temperature, add 0.3 g of Vulcan XC-72 activated carbon to 150 mL of water, and sonicate to make the activated carbon dispersed evenly to obtain the first suspension; add 0.1 g of H 2 PdCl 4 Add dropwise to the first suspension, stir for 5h, make H 2 PdCl 4 Fully adsorb on the surface of activated carbon to obtain a second suspension; adjust the pH of the second suspension to 11.5 with KOH solution, and stir at room temperature for 10 hours to obtain a third suspension; filter and wash the third suspension with water and drying to obtain a carbon-supported palladium oxide nano-cluster catalyst.

[0048] The carbon-supported palladium oxide nanocluster catalyst of Example 2 was observed by transmission electron microscope, and its particle size distribution was analyzed, and the results were similar to those of Example 1. X-ray analysis was performed on the carbon-supported palladium oxide nanocluster catalyst of Example 2, and the results were similar to thos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com