Oil and gas field oil sludge anaerobic cracking product carbonaceous carbon-based fertilizer and preparation method thereof

A technology for pyrolysis products and sludge, which is applied in the direction of inorganic fertilizers, calcium fertilizers, nitrogen fertilizers, etc., can solve the problem of not being able to make good use of carbon in oil and gas field sludge pyrolysis solid products, and achieve scientific design, large specific surface area, and reduced Effects of diseases and pests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

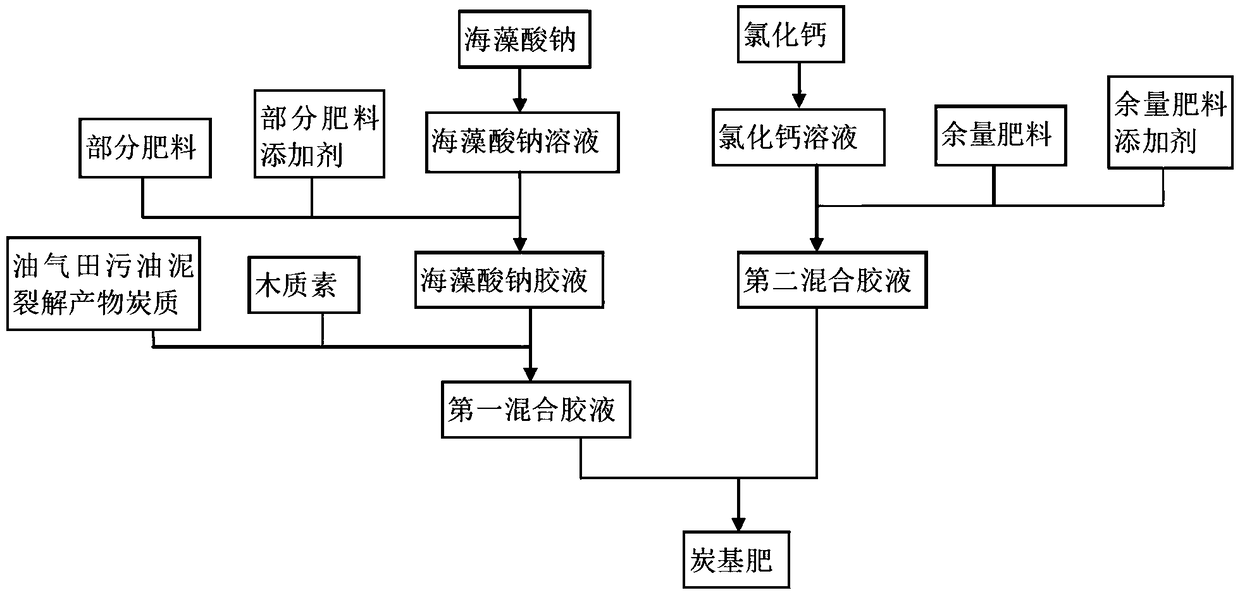

[0042] A method for preparing a carbonaceous carbon-based fertilizer produced by anaerobic cracking of sludge from oil and gas fields, comprising the following steps:

[0043] Step 1. Preparation of sodium alginate glue: add water to sodium alginate to make sodium alginate solution, then add some fertilizers and some fertilizer additives, mix well to obtain sodium alginate glue;

[0044]Step 2. Prepare the first mixed glue: after the oil and gas field sewage sludge cracking product charcoal and lignin are evenly mixed, then mixed with the sodium alginate glue evenly to obtain the first mixed glue;

[0045] Step 3. Prepare the second mixed glue: add water to calcium chloride to make a calcium chloride solution, then add the surplus fertilizer and the surplus fertilizer additive to mix to obtain the second mixed glue;

[0046] Step 4. Cross-linking reaction: adding the first mixed glue solution to the second mixed glue solution to carry out cross-linking reaction to obtain the c...

Embodiment 1

[0051] This example provides the preparation of the carbon-based fertilizer of the present invention.

[0052] The raw material is composed of the following components by weight: 60 parts of charcoal (carbon content 20 wt%), 20 parts of lignin, 5 parts of sodium alginate, 10 parts of urea, 1 part of polyglutamic acid, chlorine Calcium 4 parts.

[0053] The preparation method is:

[0054] Step 1. Preparation of sodium alginate glue: add water to sodium alginate to make a sodium alginate solution with a mass concentration of 0.5-%, then add part of urea and part of polyglutamic acid, and mix evenly to obtain sodium alginate glue; Wherein, the amount of urea added is 10wt% of the total amount of urea, and the added polyglutamic acid is 1wt% of the total amount of polyglutamic acid;

[0055] Step 2. Preparation of the first mixed glue: after the oil and gas field sewage sludge cracking product carbon and lignin are evenly mixed, they are evenly mixed with the fragrant sodium alg...

Embodiment 2

[0059] This example provides the preparation of the carbon-based fertilizer of the present invention.

[0060] The raw material is composed of the following components by weight: 60 parts of charcoal (carbon content 60wt%), 20 parts of lignin, 5 parts of sodium alginate, 10 parts of potassium chloride, 10 parts of polyaspartic acid 4 parts, 4 parts of calcium chloride.

[0061] The preparation method is:

[0062] Step 1. Preparation of sodium alginate glue: adding water to sodium alginate to make a sodium alginate solution with a mass concentration of 20%, then adding part of urea and part of polyglutamic acid, and mixing evenly to obtain sodium alginate glue; , the amount of urea added is 5wt% of the total amount of urea, and the added polyglutamic acid is 5wt% of the total amount of polyglutamic acid;

[0063] Step 2. Preparation of the first mixed glue: after the oil and gas field sewage sludge cracking product carbon and lignin are evenly mixed, they are evenly mixed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com