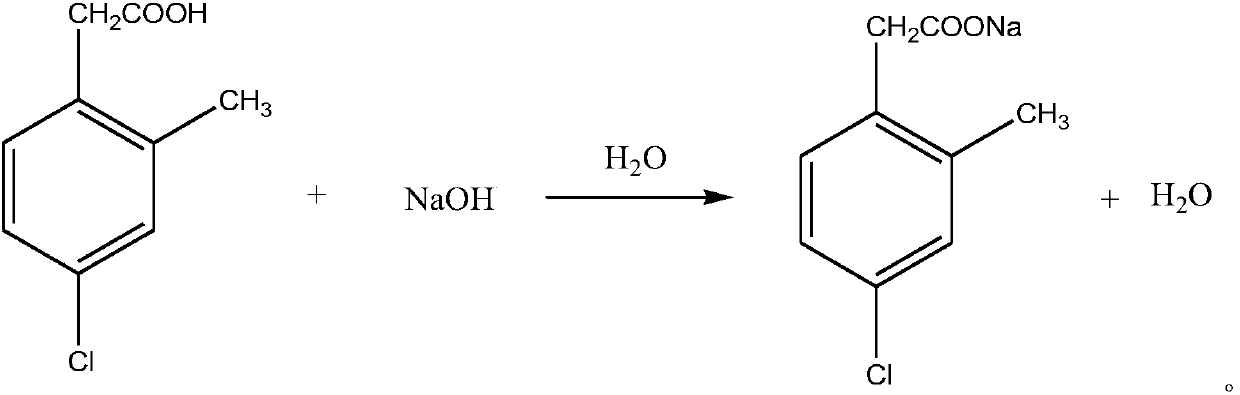

Preparation method of 2-methyl-4-sodium chlophenoxycetate

A technology for sodium chlorophenoxyacetate and solid chlorophenoxyacetic acid, applied in the chemical industry, can solve the problems of low solubility, easy blockage of the feeding pipeline of a packaging machine, crop phytotoxicity and residues, and achieves the effect of low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]With the former medicine of methanoic acid (purity 95.82%), sodium hydroxide (purity 99%) and deionized water, by the molar ratio of 1.0:1.0:0.5, i.e. the former medicine of methanoic acid (95.82%) 1000g (4.791moL), sodium hydroxide (99%) 193.57g (4.791moL), deionized water 43.12g (2.395moL), put into the stainless steel kneader with dust removal and condensation device in order, and start the dust removal and condensation The device is used to make it work, and the kneader is turned on to adjust the speed-regulating motor so that the speed reaches 500r / min. The material in the kneader changes from solid to pasty and finally to viscous liquid. When the temperature in the kneader reaches 100-120°C, continue kneading the material for 60 minutes, and when the temperature drops to 40-50°C, continue kneading for 10 minutes, and the output is 1116g of 2-methyl-4-chloride sodium salt, with a content of 95.30% and a moisture content of 0.45%. , Collect 121g of condensed water fo...

Embodiment 2

[0044] With the former medicine of methanoic acid (purity 95.82%), sodium hydroxide (purity 99%) and deionized water, by the molar ratio of 1.0:1.05:0.7, i.e. the former medicine of methanoic acid (95.82%) 1000g (4.791moL), sodium hydroxide (99%) 203.25g (5.03moL), deionized water 60.36g (3.3537moL), put into the stainless steel kneader with dust removal and condensation device in order, and turn on the dust removal and condensation device to make it work. Turn on the kneader, adjust the speed-regulating motor so that the speed reaches 700r / min, and the material in the kneader changes from solid to paste and finally to viscous liquid. When the temperature of the kneader reaches 100-120°C, keep the temperature and the rotation speed and continue kneading the material for 55 minutes. When the temperature drops to 40-50°C, continue kneading for 10 minutes, and the material is discharged to obtain 1127g of 2-methyl-4-chloride sodium salt with a content of 94.36 %, the moisture co...

Embodiment 3

[0046] With the former medicine of methanoic acid (purity 95.82%), sodium hydroxide (purity 99%) and deionized water, by the molar ratio of 1.0:1.1:0.9, i.e. the former medicine of methanoic acid (95.82%) 1000g (4.791moL), sodium hydroxide (99%) 212.92g (5.270moL), deionized water 77.61g (4.3119moL), put into the stainless steel kneader with dust removal and condensation device in order, and start the dust removal and condensation The device is used to make it work, and the kneader is turned on to adjust the speed-regulating motor so that the speed reaches 900r / min. The material in the kneader changes from solid to pasty and finally to viscous liquid. When the temperature in the kneader reaches 100-120°C, maintain this temperature and rotate speed to continue kneading the material for 50 minutes, and when the temperature drops to 40-50°C, continue kneading for 10 minutes to obtain 1140.35g of 2-methyl-4-chloride sodium salt raw material. The content is 93.27%, the moisture con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com