Bridge damping support

A technology for shock-absorbing bearings and bridges, applied in the field of bridge shock-absorbing bearings, can solve problems such as the inability to apply pot-type rubber bearings well, and achieve outstanding mechanical properties, enhanced mechanical properties, tensile and tear resistance. high crack strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

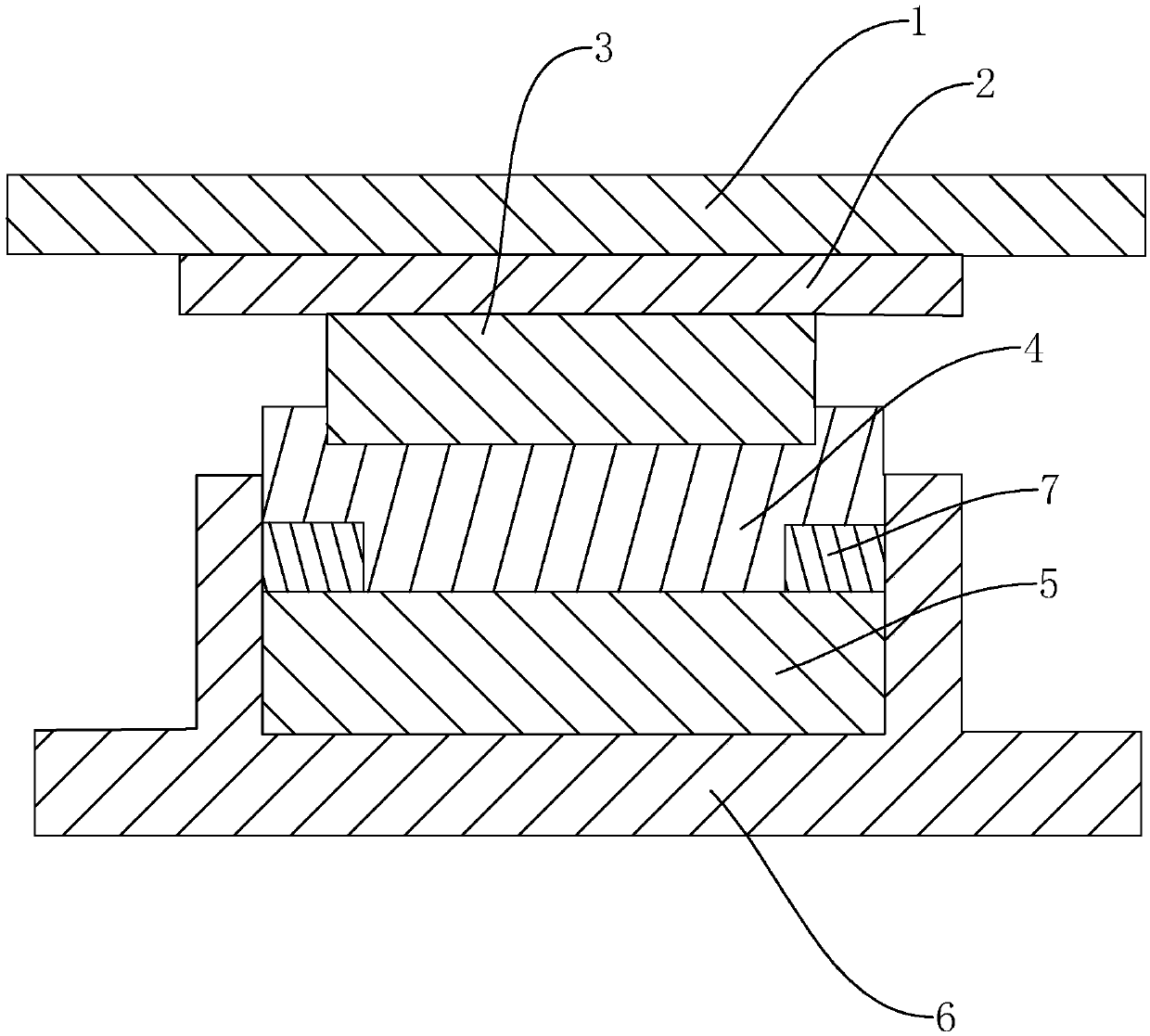

[0042] A bridge shock-absorbing bearing, such as figure 1 As shown, it includes a top plate 1, a stainless steel plate 2, a polytetrafluoroethylene plate 3, a middle steel plate 4, a rubber block 5 and a bottom basin 6 from top to bottom. The rubber block 5 is placed at the bottom of the bottom basin 6, the middle steel plate 4 is partly placed in the bottom basin 6, and a sealing ring 7 is arranged between the rubber block 5 and the middle steel plate 4.

Embodiment 2

[0044] The rubber block in embodiment one comprises the following parts by weight:

[0045] 60 parts of natural rubber;

[0046] Butadiene rubber 25 parts;

[0047] 1 part sulfur;

[0048] 3 parts of nano zinc oxide;

[0049] 2 parts stearic acid;

[0050] 0.8 part of zinc dialkyldithiophosphate;

[0051] 2 parts of silane coupling agent;

[0052] 20 parts of reinforcing agent, the reinforcing agent is made of diatomite and organic montmorillonite in a ratio of 1:1 by weight, the particle size of diatomite is 15 μm, and the particle size of organic montmorillonite is 5 μm;

[0053] 25 parts of carbon black;

[0054] Lecithin 1 part;

[0055] Magnesium oxide 0.2 parts.

[0056] The preparation method of rubber block is as follows:

[0057] Step 1: Bake 60 parts of natural rubber in an oven for 2 hours, then take it out into an open mill, add 1 part of lecithin and 25 parts of carbon black, and knead for 5 minutes at a reaction temperature of 160°C;

[0058] Step 2: Pu...

Embodiment 3

[0063]The rubber block in embodiment one comprises the following parts by weight:

[0064] 90 parts of natural rubber;

[0065] Butadiene rubber 40 parts;

[0066] 3 parts sulfur;

[0067] 6 parts of nano zinc oxide;

[0068] 4 parts stearic acid;

[0069] 1.5 parts of zinc dialkyldithiophosphate;

[0070] 5 parts of silane coupling agent;

[0071] 30 parts of reinforcing agent, the reinforcing agent is made of diatomite and organic montmorillonite in a ratio of 1:1 by weight, the particle size of diatomite is 30 μm, and the particle size of organic montmorillonite is 10 μm;

[0072] 35 parts of carbon black;

[0073] 3 parts lecithin;

[0074] Magnesium oxide 0.5 part.

[0075] The preparation method of rubber block is as follows:

[0076] Step 1: Bake 90 parts of natural rubber in an oven for 2 hours, then take it out to an open mill, add 3 parts of lecithin and 35 parts of carbon black, and knead for 5 minutes at a reaction temperature of 160°C;

[0077] Step 2: P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com