Preparation method of fish protein peptide

A technology of fish protein and fish paste, which is applied in the biological field, can solve the problems of high cost, difficult hydrolysis efficiency in large-scale industrial production, and long enzymatic hydrolysis time of small peptides, so as to increase production, improve flavor and nutritional value, and be cheap and easy to obtain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

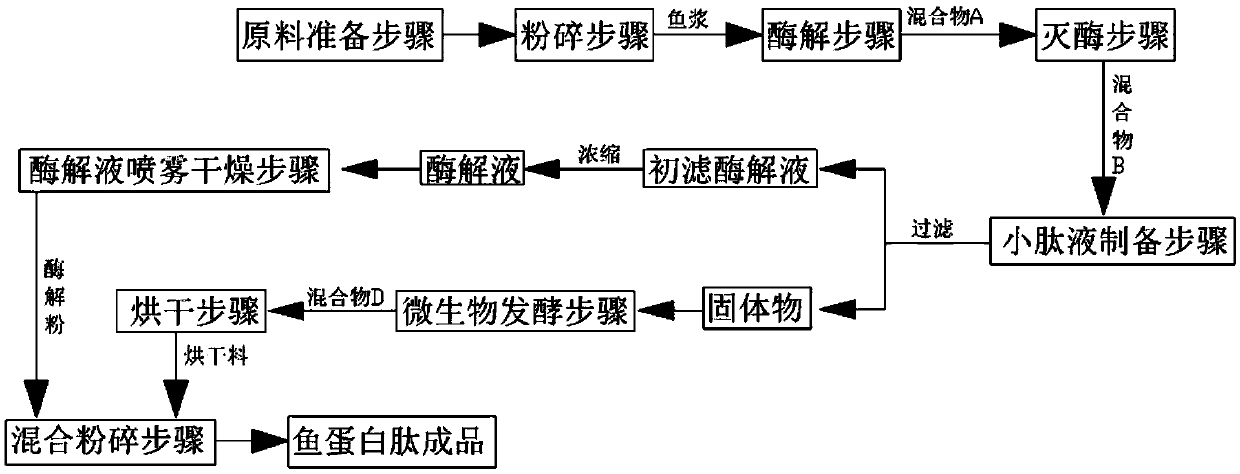

[0047] The preparation method of a kind of fish protein peptide in embodiment 1 is basically as attached figure 1 As shown, the specific steps are as follows:

[0048] Raw material preparation steps: Prepare raw materials, raw materials include marine low-value small miscellaneous fish and aquatic product scraps, among which marine low-value small miscellaneous fish mainly include anchovy, shrimp, plucked headfish, crane needle fish and sea dragon fish; aquatic products Offals include fish heads, skins, tails and viscera;

[0049] Crushing step: mix the frozen low-value marine fish and aquatic product scraps with water, and the mass ratio of raw materials to water is 1:2, thaw the raw materials with water, and remove them after they are thawed and dispersed; The final raw material is put into the pulverizer, and the pulverizer is started to pulverize to form fish paste, and the mesh number of the fish paste is less than or equal to 10, and then the fish paste is placed in the...

Embodiment 2

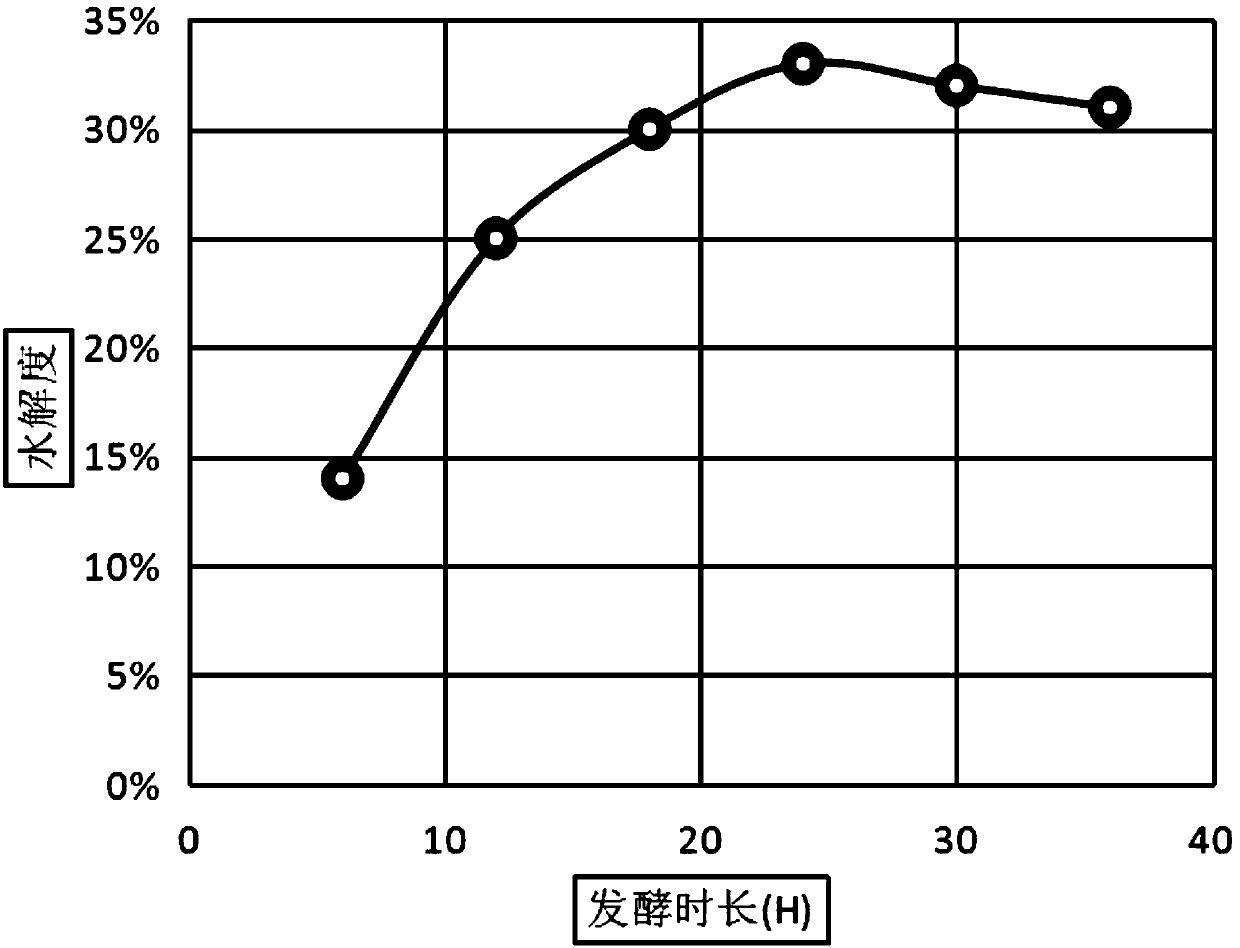

[0058] The difference between embodiment 2 and embodiment 1 is that, as figure 2 As shown, in the microbial fermentation step, the fermentation time used is 36h. After this period of microbial fermentation and hydrolysis, the mass of fish protein peptides obtained from the hydrolysis of raw materials is 31% of the total mass of raw materials. Compared with Example 1 The degree of hydrolysis of raw materials has been improved.

Embodiment 3

[0060] The difference between embodiment 3 and embodiment 1 is that, as figure 2 As shown, in the microbial fermentation step, the fermentation time used is 30h. After this period of microbial fermentation and hydrolysis, the mass of fish protein peptides obtained from the hydrolysis of raw materials is 32% of the total mass of raw materials. Compared with Example 1 The degree of hydrolysis of raw materials has been improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com