Waterborne anti-slip waxy feeling treatment agent for synthetic leather and preparation method of treatment agent

A synthetic leather and treatment agent technology, applied in fiber treatment, improved handle fiber, textiles and papermaking, etc., to achieve high production efficiency, good anti-slip effect, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

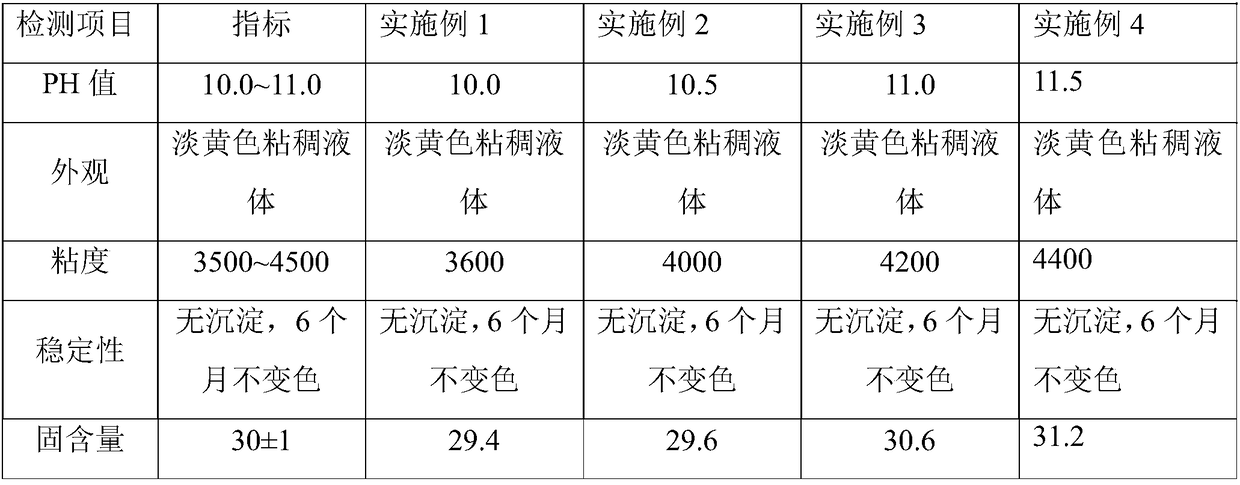

Examples

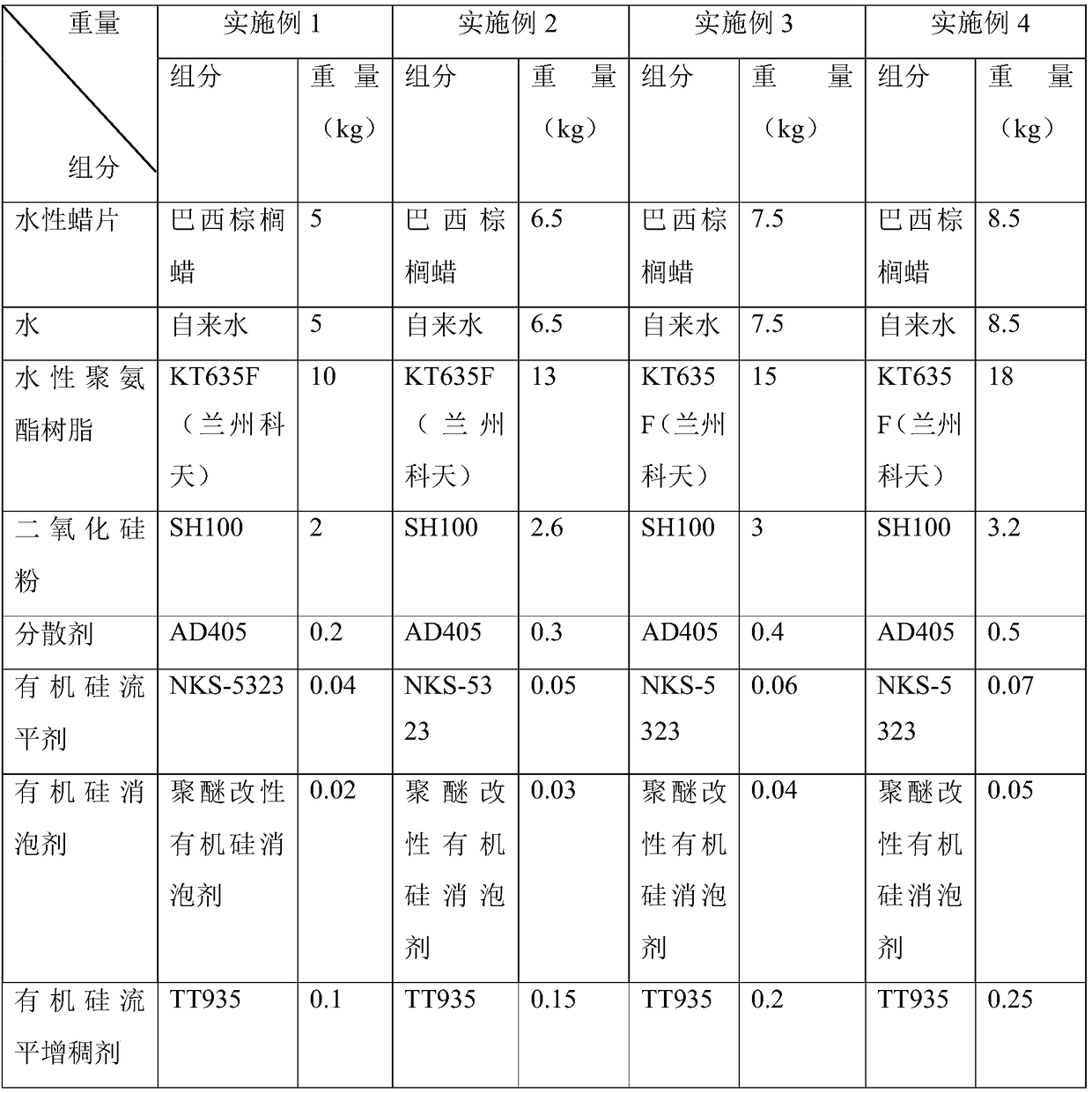

Embodiment 1

[0033] A kind of preparation of synthetic leather water-based anti-slip waxy feeling treatment agent, comprises the following steps:

[0034] 1) Take by weighing 5kg of carnauba wax and 5kg of tap water, add to a mixing container, and fully stir until the wax flakes dissolve;

[0035] 2) Take by weight the KT635F water-based polyurethane resin of 10kg, add the wax flake aqueous solution mixed in step 1), then add the superfine silica powder SH100 of 2kg by weight, the dispersant AD405 of 0.2kg, the dispersant AD405 of 0.04kg Silicone leveling agent NKS-5323, 0.01kg polyether modified silicone defoamer, stirred for 2 hours, stirring speed is 400r / min;

[0036] 3) Then add 0.1 kg of silicone leveling thickener TT935 and 0.01 kg of polyether modified silicone defoamer in parts by weight, and stir for 0.5 hours at a stirring speed of 300 r / min;

[0037] 4) The mixture prepared in step 3) is filtered to obtain the water-based anti-slip waxy treatment agent for synthetic leather. ...

Embodiment 2

[0039] A kind of preparation of synthetic leather water-based anti-slip waxy feeling treatment agent, comprises the following steps:

[0040] 1) Weigh 6.5kg of carnauba wax and 6.5kg of tap water, add to a mixing container, and fully stir until the wax flakes dissolve;

[0041] 2) take by weight the KT635F water-based polyurethane resin that is 13kg, add step 1) the mixed wax chip aqueous solution, then add the superfine silica powder SH100 that is 2.6kg, the dispersant AD405 of 0.3kg in parts by weight, 0.05kg of silicone leveling agent NKS-5323, 0.015kg of polyether modified silicone defoamer, stirred for 2 hours at a stirring speed of 400r / min;

[0042] 3) Add 0.15 kg of silicone leveling thickener TT935 and 0.015 kg of polyether modified silicone defoamer in parts by weight, and stir for 0.5 hour at a stirring speed of 200 r / min;

[0043] 4) The mixture prepared in step 3) is filtered to obtain the water-based anti-slip waxy treatment agent for synthetic leather.

Embodiment 3

[0045] A kind of preparation of synthetic leather water-based anti-slip waxy feeling treatment agent, comprises the following steps:

[0046] 1) Weigh 7.5kg of carnauba wax and 7.5kg of tap water, add to a mixing container, and fully stir until the wax flakes dissolve;

[0047] 2) Weigh the KT635F water-based polyurethane resin that is 15kg in parts by weight, add the wax chip aqueous solution mixed in step 1), then add the ultrafine silica powder SH100 that is 3kg in parts by weight, the dispersant AD405 of 0.4kg, 0.06 kg of silicone leveling agent NKS-5323, 0.02kg of polyether modified silicone defoamer, stirred for 2 hours at a stirring speed of 400r / min;

[0048] 3) Then add 0.2kg of silicone leveling thickener TT935 and 0.02kg of polyether modified silicone defoamer in parts by weight, and stir for 0.5 hours at a stirring speed of 300r / min;

[0049] 4) The mixture prepared in step 3) is filtered to obtain the water-based anti-slip waxy treatment agent for synthetic leath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com