Tomato industrialized seedling growing system and management method

A system management and factory technology, applied in the field of agricultural cultivation, can solve problems such as low efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

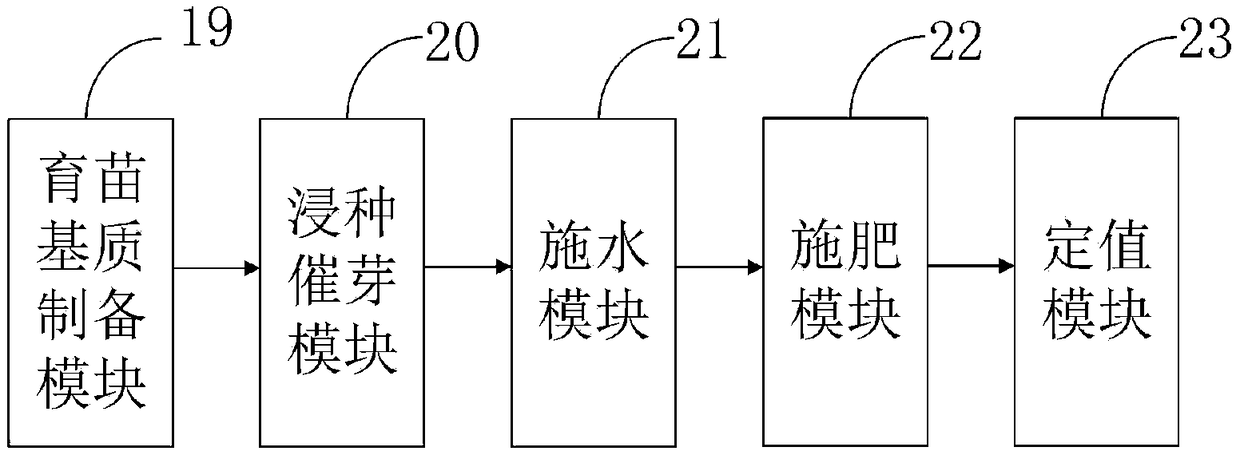

[0110] Described seedling-raising matrix preparation module, its seedling-raising matrix preparation method comprises:

[0111] Step 1: The seedling raising substrate is composed of 6-10 parts of corn stalk powder, 5-7 parts of mushroom dregs, 7-9 parts of pine sawdust, 6-8 parts of cotton seed hulls, 1-2 parts of potassium dihydrogen phosphate, and sulfuric acid in parts by mass. 1-2 parts of potassium, 1-3 parts of urea, 3-5 parts of peat, 3-4 parts of sand, 6-10 parts of pine needle soil and 10-15 parts of vegetable garden soil;

[0112] Step 2: Mix the weighed straw powder, mushroom dregs, pine sawdust and cotton seed husks evenly, stack and ferment;

[0113] Step 3: adding the weighed potassium dihydrogen phosphate, potassium sulfate and urea into the fermentation, and composting and fermenting to obtain organic fertilizer;

[0114] Step 4: Weighing the peat and adding it to the organic fertilizer while stirring, and spraying water continuously during the stirring proces...

Embodiment 1

[0172] The seedling raising substrate provided by the embodiment of the present invention consists of 6 parts of corn stalk powder, 5 parts of mushroom dregs, 7 parts of pine sawdust, 6 parts of cotton seed hulls, 1 part of potassium dihydrogen phosphate, 1 part of potassium sulfate, and 1 part of urea in parts by mass. , 3 parts of peat, 3 parts of sand, 6 parts of pine needle soil and 10 parts of vegetable garden soil;

Embodiment 2

[0174] The seedling raising substrate provided by the embodiment of the present invention consists of 8 parts of corn stalk powder, 6 parts of mushroom dregs, 8 parts of pine sawdust, 7 parts of cotton seed hulls, 1.5 parts of potassium dihydrogen phosphate, 1.5 parts of potassium sulfate, and 2 parts of urea in parts by mass. , 4 parts of peat, 3.5 parts of sand, 8 parts of pine needle soil and 12.5 parts of vegetable garden soil;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com