Low-calorie whole-grain coarse-cereal crisp biscuit and manufacturing method thereof

A technology for crisp biscuits and whole grains, which is applied in the field of low-calorie whole grain and miscellaneous grain biscuits and their preparation, can solve the problems of incomplete nutrients and high calorie, and achieve the effects of equal bulkiness, reduced calorie, and equal brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1. The preparation method of low-calorie whole grain multigrain crispy biscuits.

[0029] The low-calorie whole grain miscellaneous grain crispy biscuit described in this embodiment is made of the following raw materials: 360 parts of miscellaneous grain mixed powder, 80 parts of erythritol, 50 parts of galactooligosaccharide, 140 parts of butter, 120 parts of egg, 100 parts peanut butter, 100 parts milk, 40 parts resistant dextrin, 20 parts whey protein powder, 20 parts white kidney bean extract, 8 parts chia seeds, 8 parts modified starch, 8 parts baking soda, 4 parts baking powder and 0.6 parts of selenium-enriched yeast.

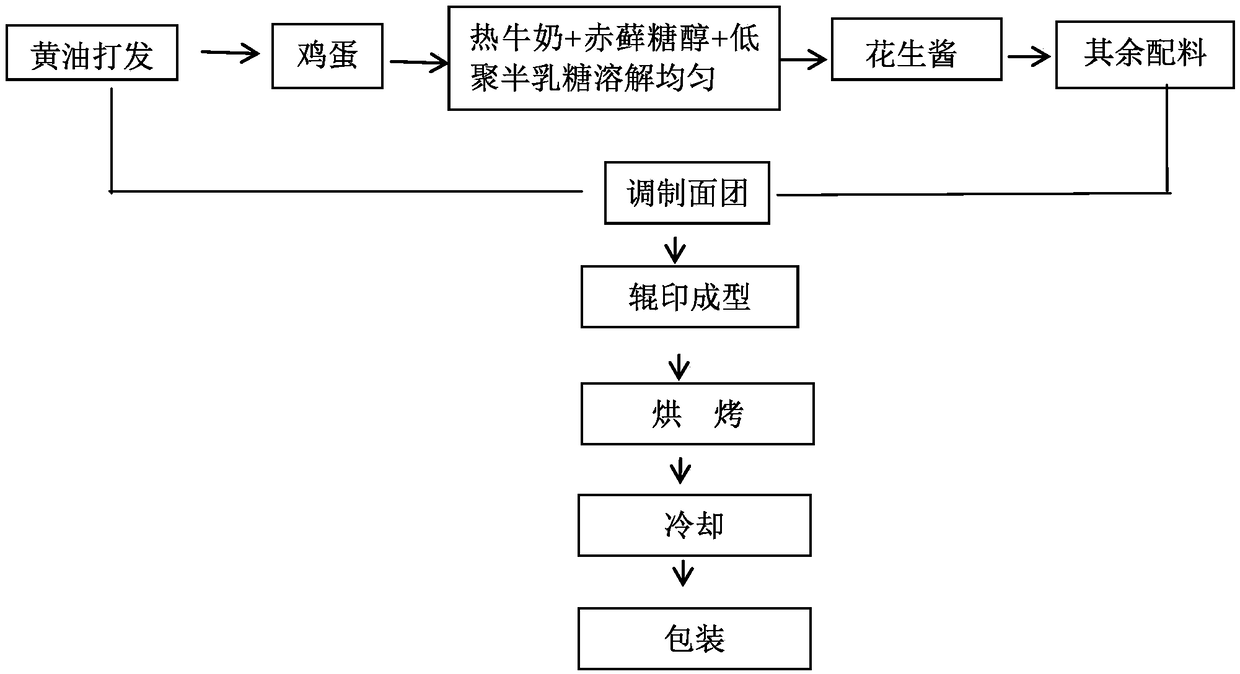

[0030] Attached below figure 1 Describe the preparation method of the low-calorie whole grain multigrain crispy biscuit of the present invention:

[0031] 1) Soften the butter at room temperature, and quickly whip until the butter becomes larger in volume, whitish in color, and feels fluffy. Add egg liquid in small amounts, and stir w...

Embodiment 2

[0038] Example 2. Repeat Example 1. The difference from Example 1 is that the low-calorie whole grain miscellaneous grain crispy biscuit is made of the raw materials of the following weight: 300 parts of miscellaneous grain mixed powder, 80 parts of erythritol, oligomeric 20 parts galactose, 80 parts butter, 100 parts eggs, 80 parts peanut butter, 80 parts milk, 20 parts resistant dextrin, 10 parts whey protein powder, 10 parts white kidney bean extract, 5 parts chia seeds, modified starch 5 parts, 2 parts of baking soda, 2 parts of baking powder and 0.2 parts of selenium-enriched yeast.

[0039] Refer to Example 1 for the specific preparation method of biscuits.

Embodiment 3

[0040] Example 3. Repeat Example 1. The difference from Example 1 is that the low-calorie whole grain miscellaneous grain crispy biscuit is made of the raw materials of the following weight: 400 parts of miscellaneous grain mixed powder, 120 parts of erythritol, oligomeric 80 parts galactose, 150 parts butter, 150 parts eggs, 120 parts peanut butter, 120 parts milk, 80 parts resistant dextrin, 30 parts whey protein powder, 30 parts white kidney bean extract, 10 parts chia seeds, modified starch 10 parts, 10 parts of baking soda, 10 parts of baking powder and 1.0 parts of selenium-enriched yeast. The preparation method refers to Example 1.

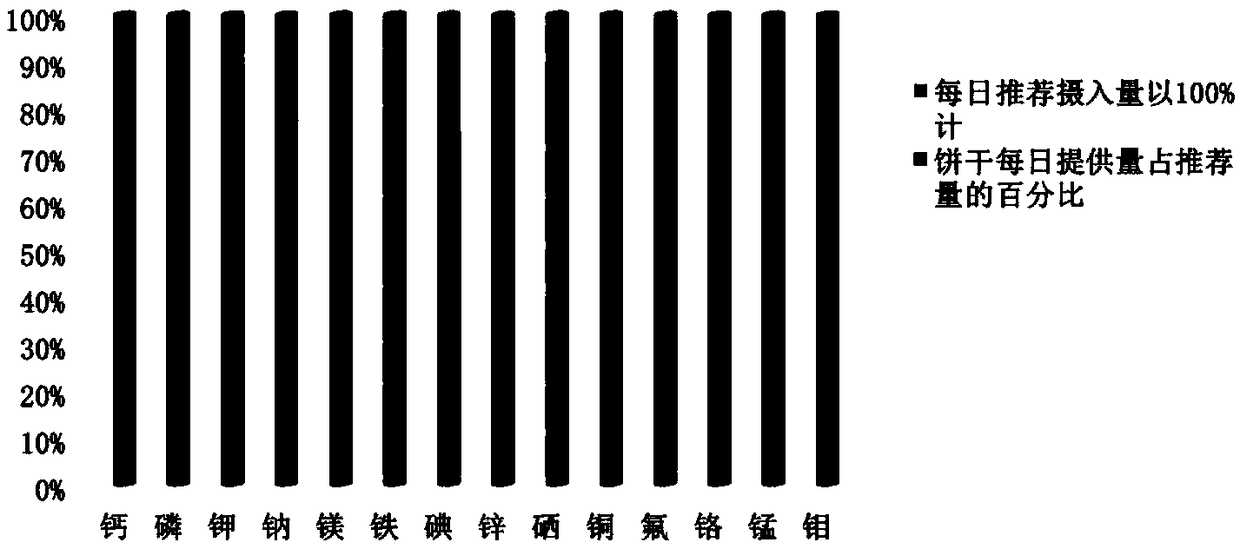

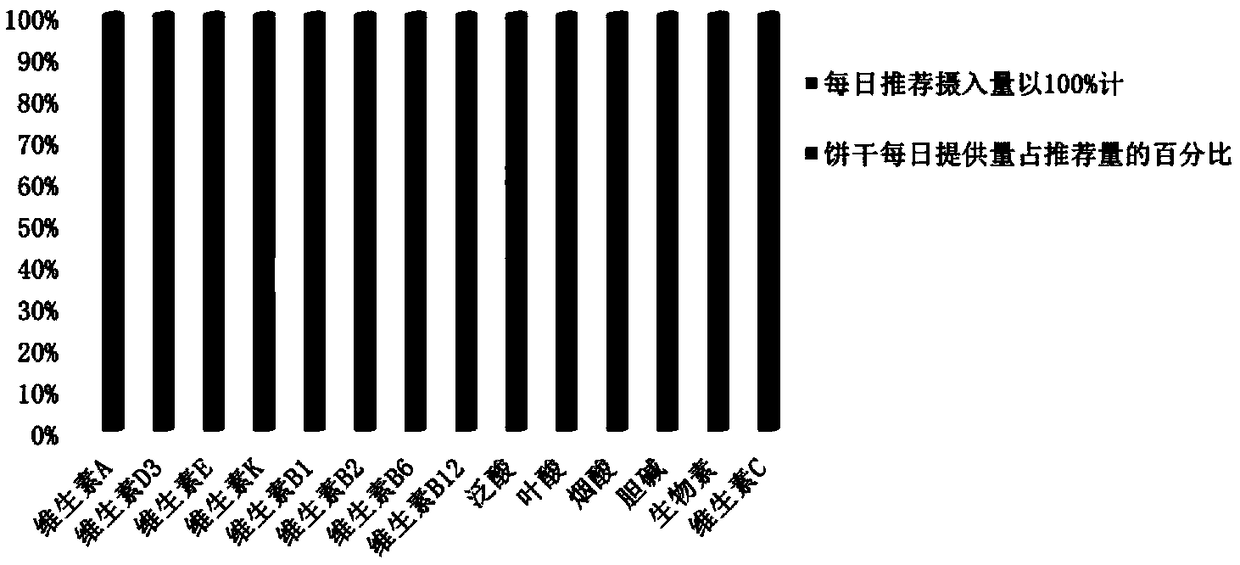

[0041] The multigrain biscuit prepared by the invention is suitable for people who lose weight and people with abnormal glucose tolerance.

[0042] For people who lose weight: NSCA (National Strength and Conditioning Association, National Physical Fitness Association) recommends that reducing calorie intake (that is, negative calorie balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com