A kind of homogeneous corn cob derived carbon electrode material and preparation method thereof

A technology of electrode materials and corn cobs, applied in chemical instruments and methods, hybrid capacitor electrodes, carbon compounds, etc., can solve problems such as difficulty in obtaining, and achieve the effects of low cost, rich raw materials, and uniform microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The collected corncobs were cleaned, dried, crushed, and sieved to obtain corncob powder particles between 10 and 18 mesh; the obtained corncob powder particles were transferred to a tube furnace and heated at a heating rate of 5 °C / min in a nitrogen atmosphere Heat at 800 °C for 2 hours, then carbonize; mix the obtained carbonized material with KOH at a mass ratio of 1:3, grind thoroughly, and heat to 800 °C at a heating rate of 5 °C / min in a nitrogen atmosphere for 2 hours to obtain an activated product ; The activated product was soaked in 1 mol / L HCl solution, then washed alternately with deionized water and alcohol, and finally dried in a drying oven at 60 °C to obtain a homogeneous corncob-derived carbon electrode material.

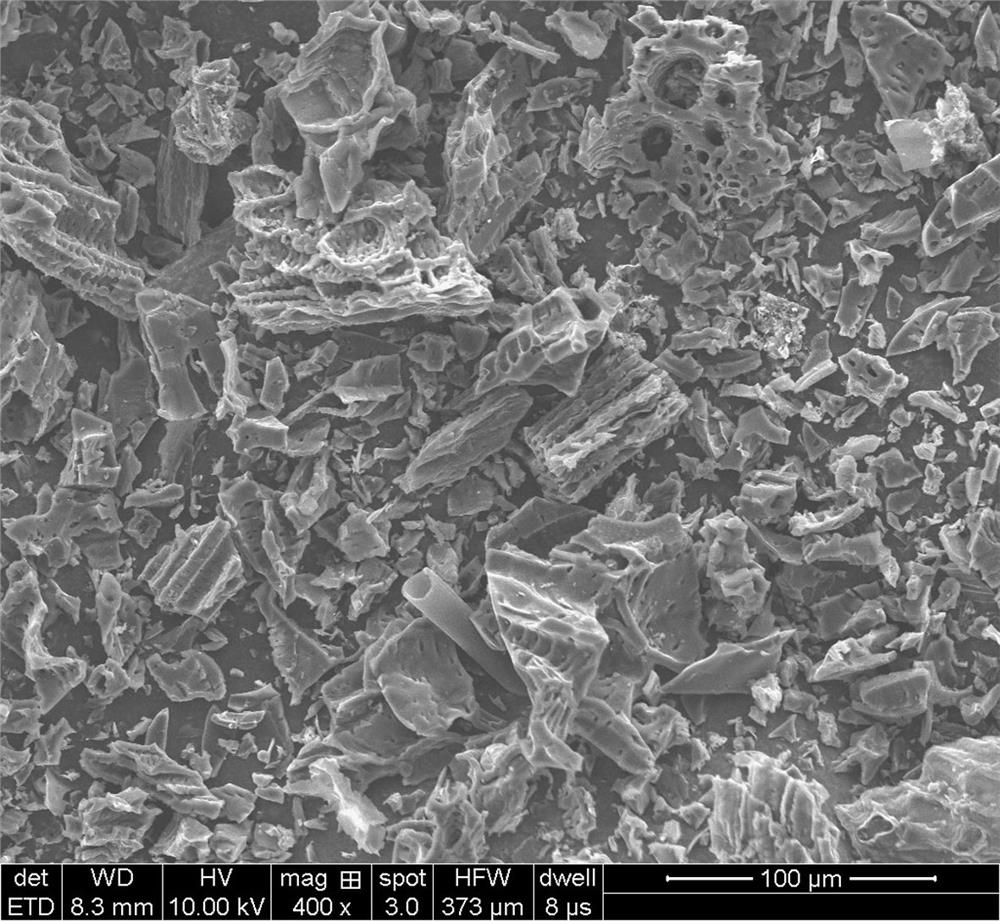

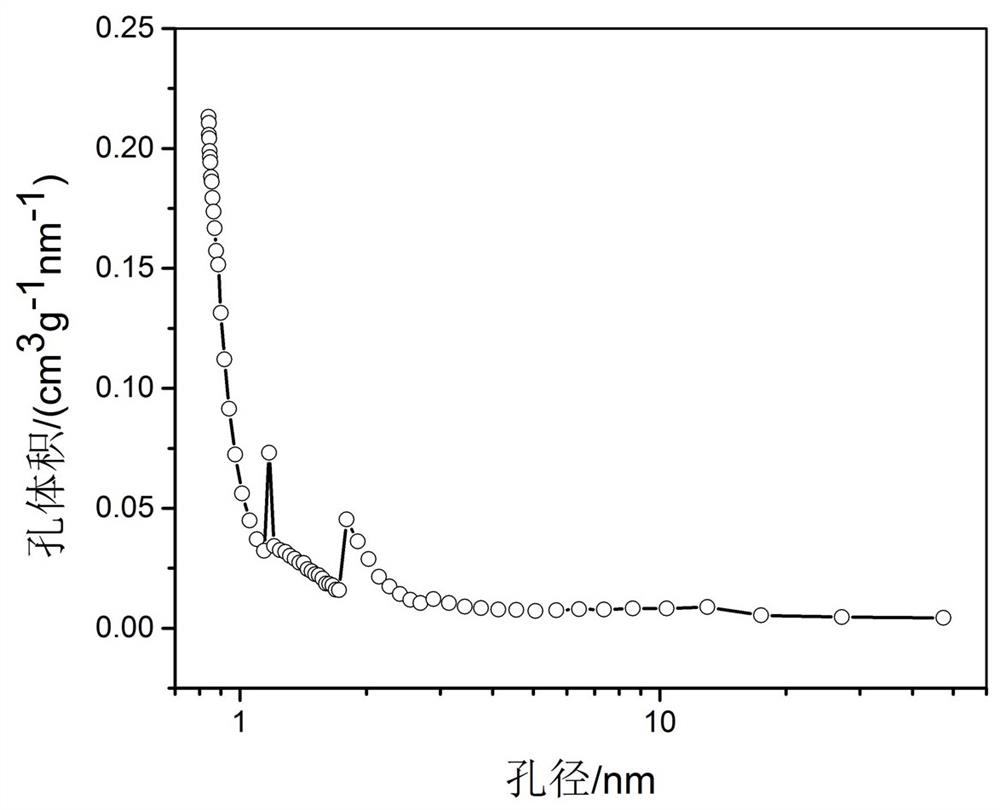

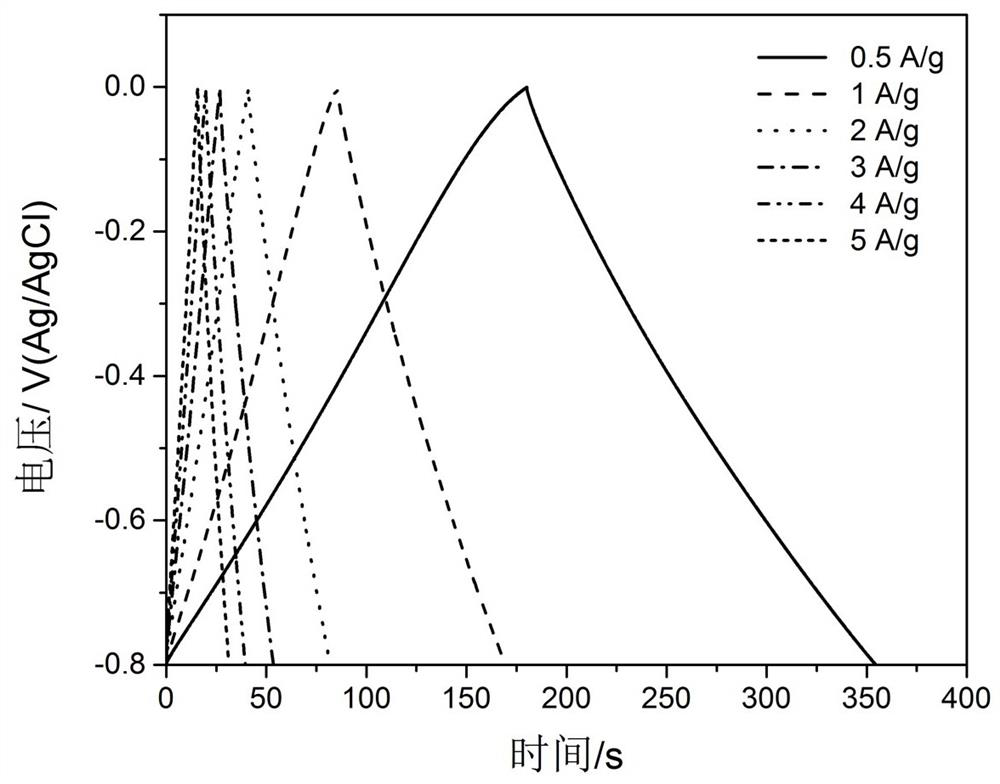

[0031] The scanning electron microscope (SEM) image of the prepared homogeneous corncob-derived carbon electrode material is shown in figure 1 shown by figure 1 It can be seen that the microstructure and particle size of the prepared activat...

Embodiment 2

[0033] The collected corncobs were cleaned, dried, crushed, and sieved to obtain corncob powder particles between 170 and 200 mesh; the obtained corncob powder particles were transferred to a tube furnace and heated at a heating rate of 20 °C / min in a nitrogen atmosphere Heat at 600 °C for 24 h, then carbonize; mix the obtained carbonized material with KOH at a mass ratio of 1:1, grind thoroughly, and heat to 1000 °C for 12 h at a heating rate of 10 °C / min in a nitrogen atmosphere to obtain activation Product; the obtained activated product was soaked in 6mol / L HCl solution, then washed alternately with deionized water and alcohol, and finally dried in a 150 °C drying oven to obtain a homogeneous corncob-derived carbon electrode material.

[0034] The scanning electron microscope (SEM) image of the prepared homogeneous corncob-derived carbon electrode material is shown in Figure 5 shown by Figure 5 It can be seen that the microstructure and particle size of the prepared act...

Embodiment 3

[0036] The collected corncobs were cleaned, dried, crushed, and sieved to obtain corncob powder particles between 325 and 400 mesh; the obtained corncob powder particles were transferred to a tube furnace and heated at a heating rate of 3 °C / min in a nitrogen atmosphere Heat at 1000 °C for 1 h, then carbonize; mix the obtained carbonized material with KOH at a mass ratio of 1:6, grind thoroughly, and heat to 600 °C at a heating rate of 20 °C / min in a nitrogen atmosphere for 24 h to obtain activation Product; the activated product was soaked in 3 mol / L HCl solution, then washed alternately with deionized water and alcohol, and finally dried in a drying oven at 50 °C to obtain a homogeneous corncob-derived carbon electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com