Preparation method of photocatalytic cement-based material

A cement-based material and photocatalysis technology, which is applied in the field of photocatalytic cement-based materials, can solve the problems of complex operation and high cost of the preparation method, and achieve the effects of accelerating the bonding rate, low cost, and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

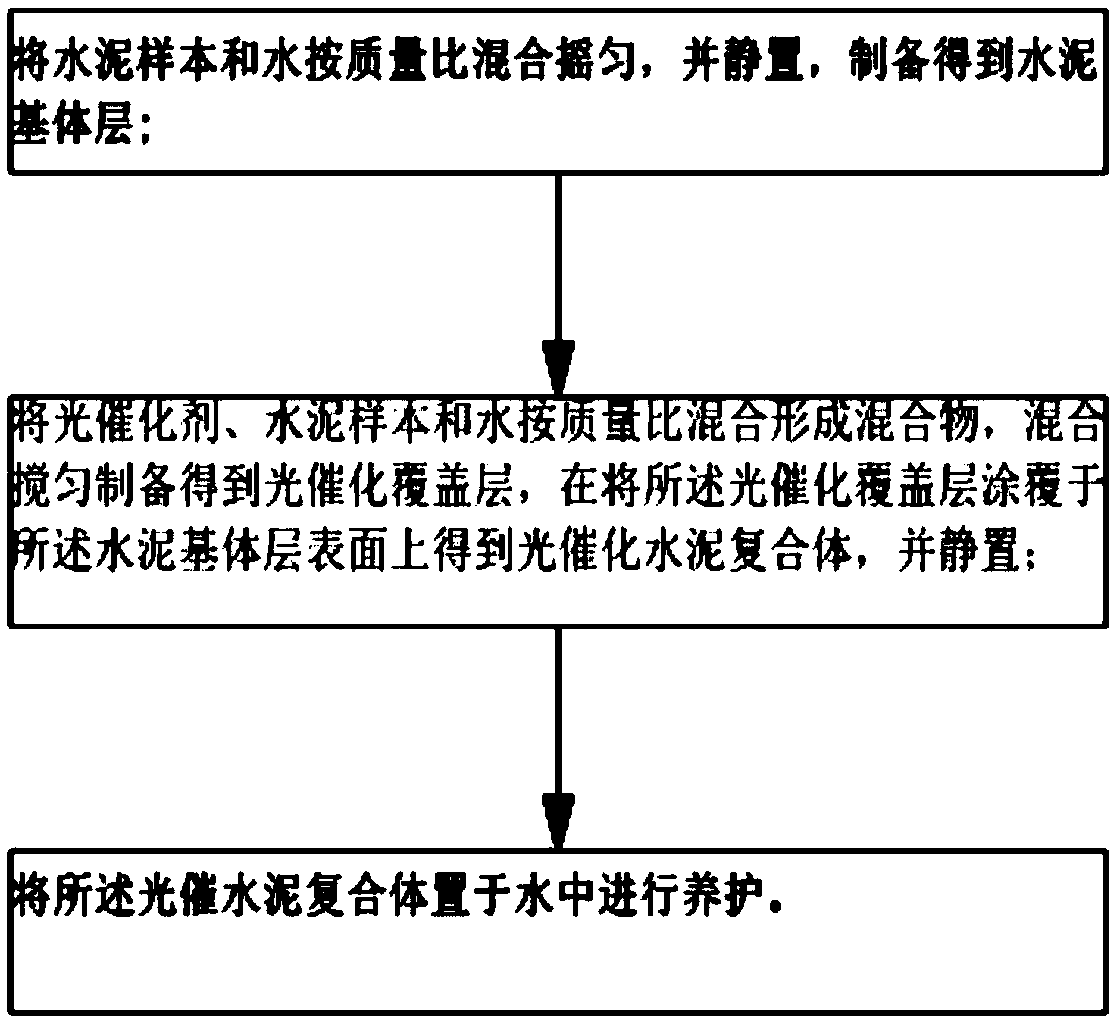

[0025] Please refer to figure 1 , the preparation method of the photocatalytic cement-based material provided by the embodiment of the present invention comprises the following steps:

[0026] Step 1, mix the cement sample and water according to the mass ratio, and let it stand to prepare the cement matrix layer;

[0027] Step 2: Mix the photocatalyst, cement sample and water according to the mass ratio to form a mixture, mix and stir well to prepare a photocatalytic covering layer, and then apply the photocatalytic covering layer on the surface of the cement matrix layer to obtain a photocatalytic cement composite, and stand still;

[0028] Step 3, placing the photocatalytic cement complex in water for curing.

[0029] The preparation method of the photocatalytic cement-based material provided by the embodiment of the present invention, firstly, prepare the cement matrix layer; secondly, prepare the photocatalytic covering layer; wherein, the cement sample in the photocatal...

Embodiment 1

[0031] Step 1, mix 100g of slag portland cement and 25g of water, put it in the mold, shake it tightly, and let it stand for 45min to prepare the cement matrix layer;

[0032] Step 2, after mixing and shaking 1.3157g of nano-titanium dioxide, 20g of slag silicate water and 5g of water, a photocatalytic covering layer is prepared, and the photocatalytic covering layer is coated on the surface of the cement matrix layer. Realize, obtain photocatalytic cement composite body, and leave standstill 1 day;

[0033] Step 3, put the photocatalytic cement complex in water for curing for 7 days, and then take it out.

[0034] The compressive strength of the photocatalytic cement composite after curing for 7 days was 24.5MPa. The thickness of the photocatalytic cover layer is 1 mm.

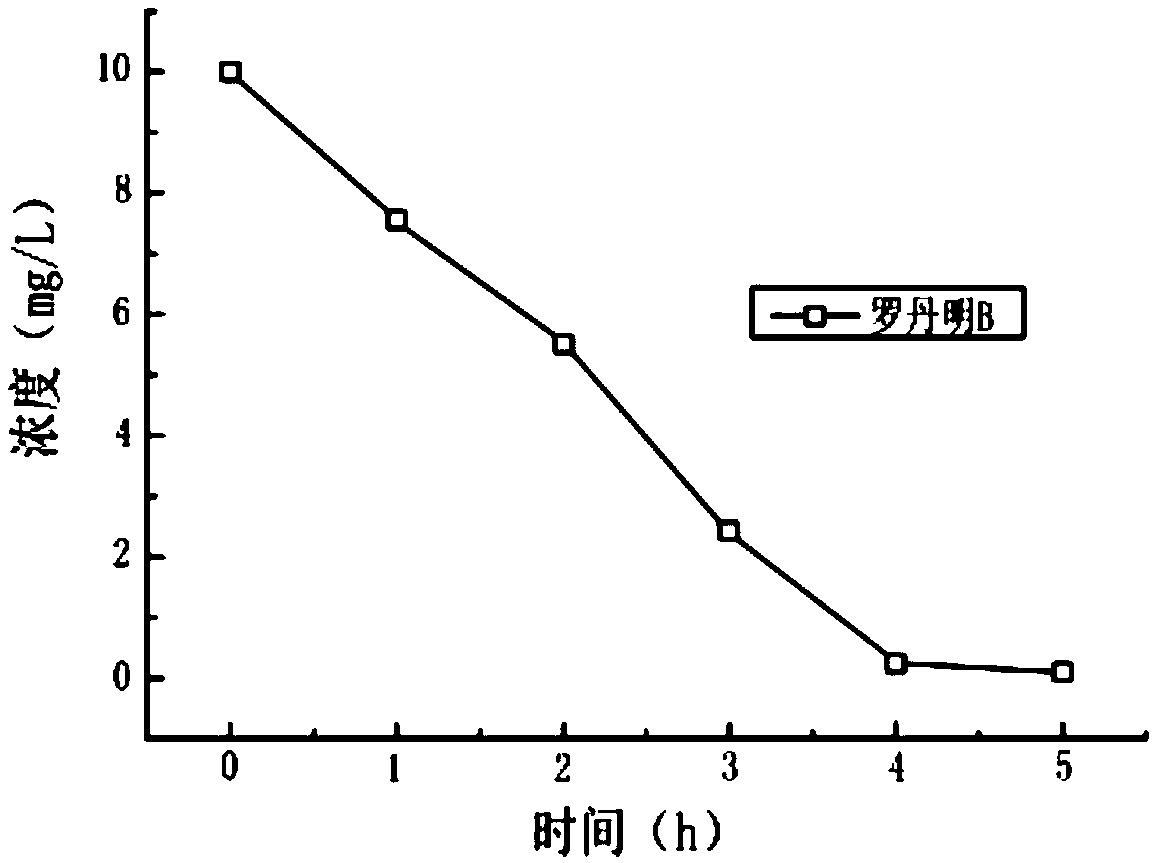

[0035] figure 2 The degradation curve of the photocatalytic cement composite prepared in Example 1 of the present invention to rhodamine B solution. Such as figure 2 As shown, under light conditions, t...

Embodiment 2

[0037] Step 1, mix 100g of pozzolanic portland cement and 50g of water, mix evenly, place in the mold, shake it tightly, and let it stand for 90min to prepare the cement matrix layer;

[0038] Step 2, after mixing and shaking 0.05g of nano-zinc oxide, 30g of pozzolanic Portland cement and 15g of water, the photocatalytic coating is prepared, and the photocatalytic coating is coated on the surface of the cement matrix layer , shaken to obtain a photocatalytic cement complex, and let it stand for 2 days;

[0039] In step 3, the photocatalytic cement complex is placed in water for curing for 1 day, and then taken out.

[0040] The compressive strength of the photocatalytic cement composite after curing for 1 day was 8.45MPa. The thickness of the photocatalytic covering layer is 0.01 mm.

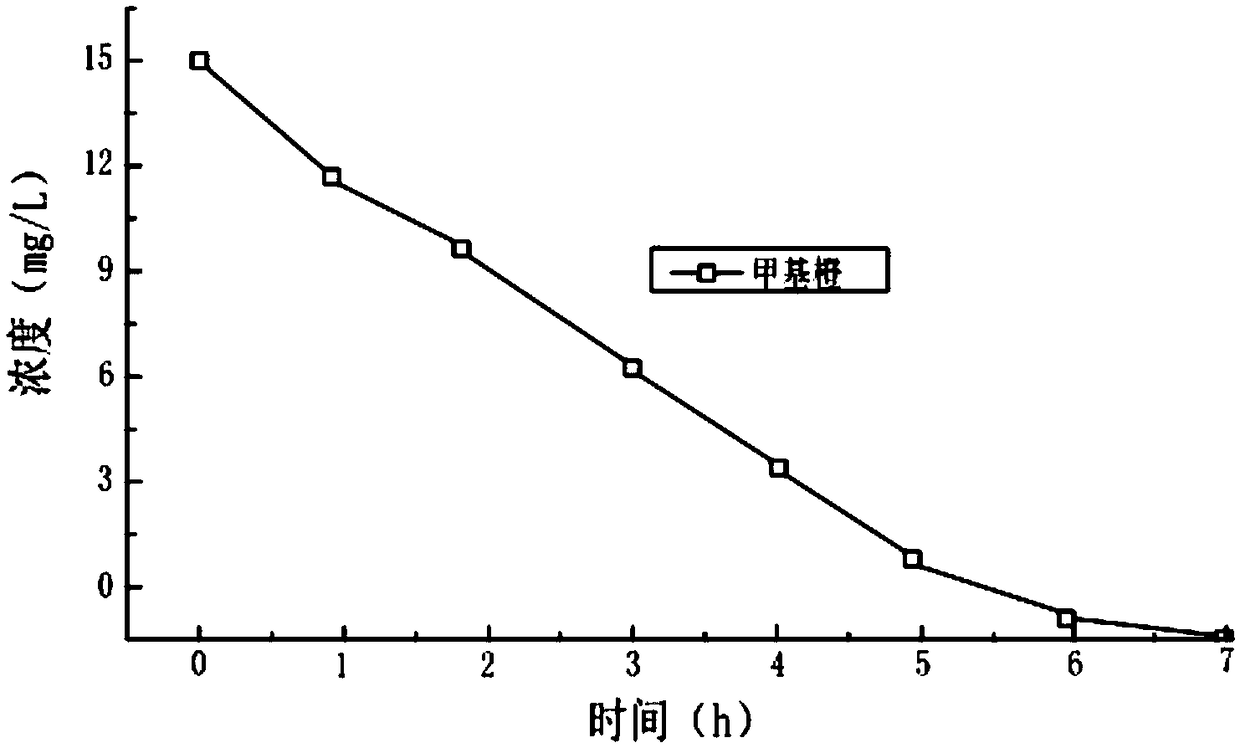

[0041] image 3 The degradation curve of the photocatalytic cement composite prepared for Example 2 of the present invention to the methyl orange solution. Such as image 3 As shown, under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com