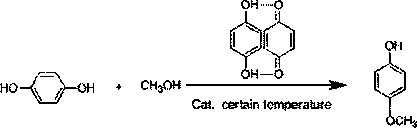

Method for synthesizing p-hydroxyanisole by taking quinhydrone as auxiliary agent or raw material

A technology of p-hydroxyanisole and quinhydrone, which is applied in the field of organic compound preparation, can solve the problem of high p-benzoquinone price, achieve high yield, reduce production cost and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

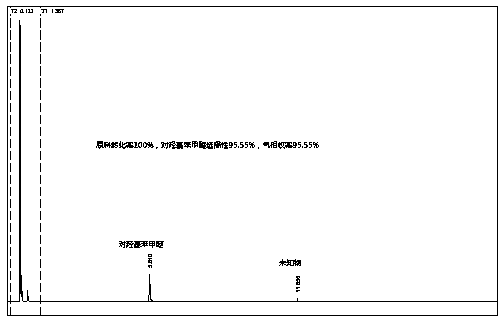

[0011] Add 1g of quinhydrone, 0.5g of phosphotungstic acid, and 7.92g of anhydrous methanol into a 50mL flask, install a condenser, and heat to 70°C with magnetic stirring. After 4 hours of reaction, stop heating, cool down, dry, filter, and perform gas chromatography The purity of the product was detected, the conversion rate of quinhydrone was 100%, and the yield of p-hydroxyanisole was 95.20%.

Embodiment 2

[0013] Add 0.3g of quinhydrone, 0.15g of phosphotungstic acid, and 2.38g of anhydrous methanol into a 50mL flask, install a condenser, and heat to 70°C with magnetic stirring. After 4 hours of reaction, stop heating, cool down, dry, filter, and gas phase The purity of the product was detected by chromatography, the conversion rate of quinhydrone was 100%, and the yield of p-hydroxyanisole was 83.02%.

Embodiment 3

[0015] Add 0.1g of quinhydrone, 0.1g of concentrated sulfuric acid, and 4g of anhydrous methanol into a 50mL flask, install a condenser, and heat to 70°C with magnetic stirring. After 4 hours of reaction, stop heating, cool down, dry, filter, and detect by gas chromatography The purity of the product, the conversion rate of quinhydrone is 100%, and the yield of p-hydroxyanisole is 95.41%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com