Halogen-containing flame-retardant polyethylene sheath material

A flame retardant polyethylene and sheathing material technology, applied in the field of sheathing materials, can solve problems such as poor resistance to environmental stress cracking, achieve excellent dielectric properties, good flexibility, and improve flame retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] As an embodiment of the present invention, the raw materials for the preparation of the halogenated flame-retardant polyethylene sheathing material further include modified polyacrylic acid and nano inorganic substances.

[0035] Polyethylene blend

[0036] In the present invention, the polyethylene-based mixture refers to a mixture of polyethylene and modified polyethylene.

[0037] Polyethylene: In the present invention, the polyethylene refers to a mixture of ultra-high molecular weight polyethylene, medium-density polyethylene and low-density polyethylene.

[0038] As an embodiment of the present invention, the ultra-high molecular weight polyethylene is branched ultra-high molecular weight polyethylene.

[0039] In the present invention, the preparation method of the ultra-high molecular weight polyethylene is as follows:

[0040] 1. In a 0.5L stainless steel stirred polymerization kettle, replace it with nitrogen three times and twice with ethylene, add 180mL ...

Embodiment approach 1

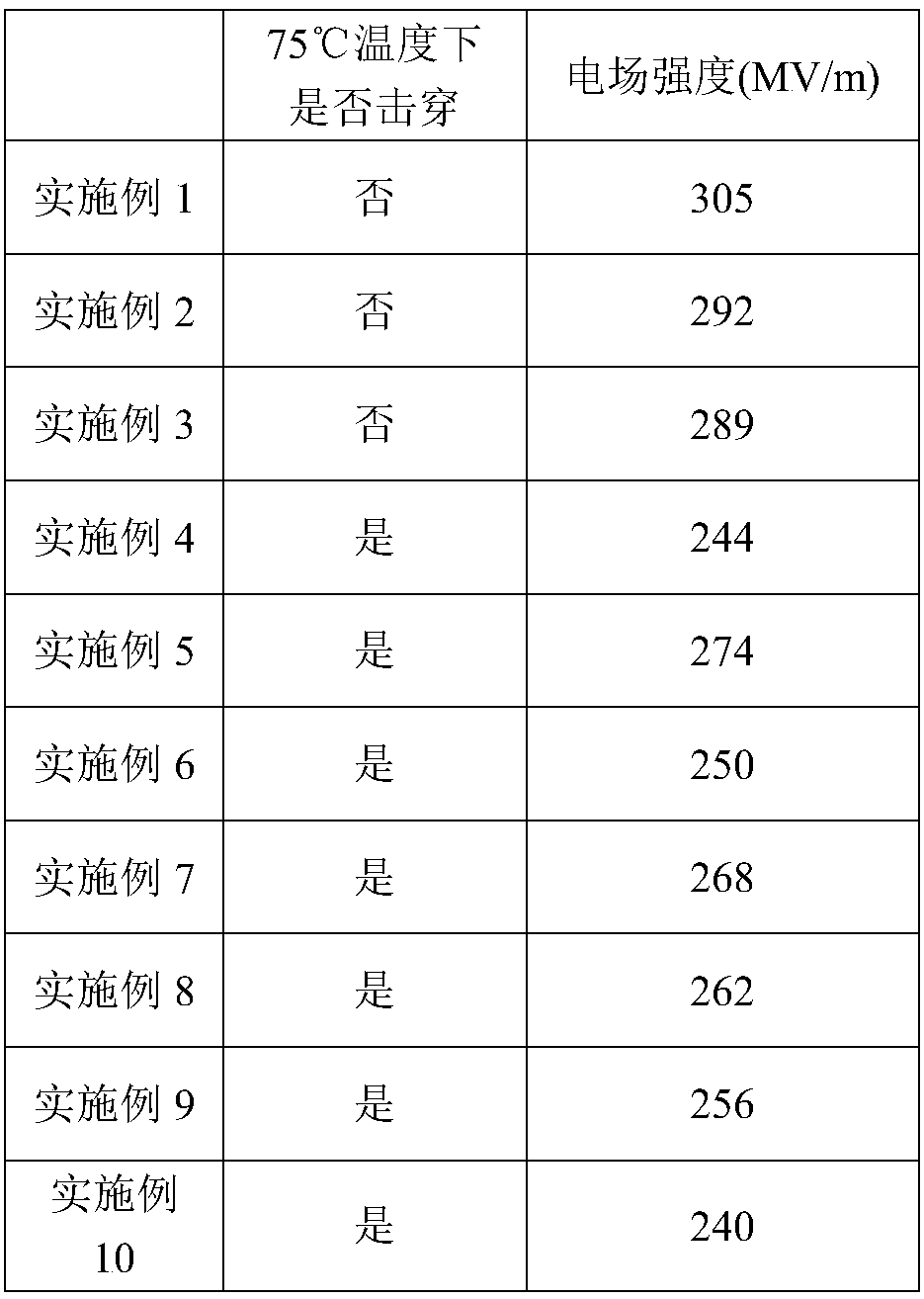

[0100] Embodiment 1. Halogenated flame-retardant polyethylene sheath material, the preparation raw materials of said halogenated flame-retardant polyethylene sheath material at least include:

[0101] Polyethylene-based compounds, antioxidants, inorganic flame retardants, halogenated flame retardants, lubricants and masterbatches.

Embodiment approach 2

[0102] Embodiment 2. The halogenated flame-retardant polyethylene sheath material described in Embodiment 1, by weight, the preparation raw materials of the halogenated flame-retardant polyethylene sheath material at least include:

[0103] 40-60 parts of polyethylene mixture, 0.1-3 parts of antioxidant, 25-40 parts of inorganic flame retardant, 10-20 parts of halogenated flame retardant, 0.1-2 parts of lubricant and 5-20 parts of color masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com