Color-variable erasable environment-friendly paint and preparation method thereof

An environmentally friendly paint and color-changing technology, which is applied to heat-sensitive paints, coatings, inks, etc., can solve the problems of casual painters and other problems, and achieve the effect of simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

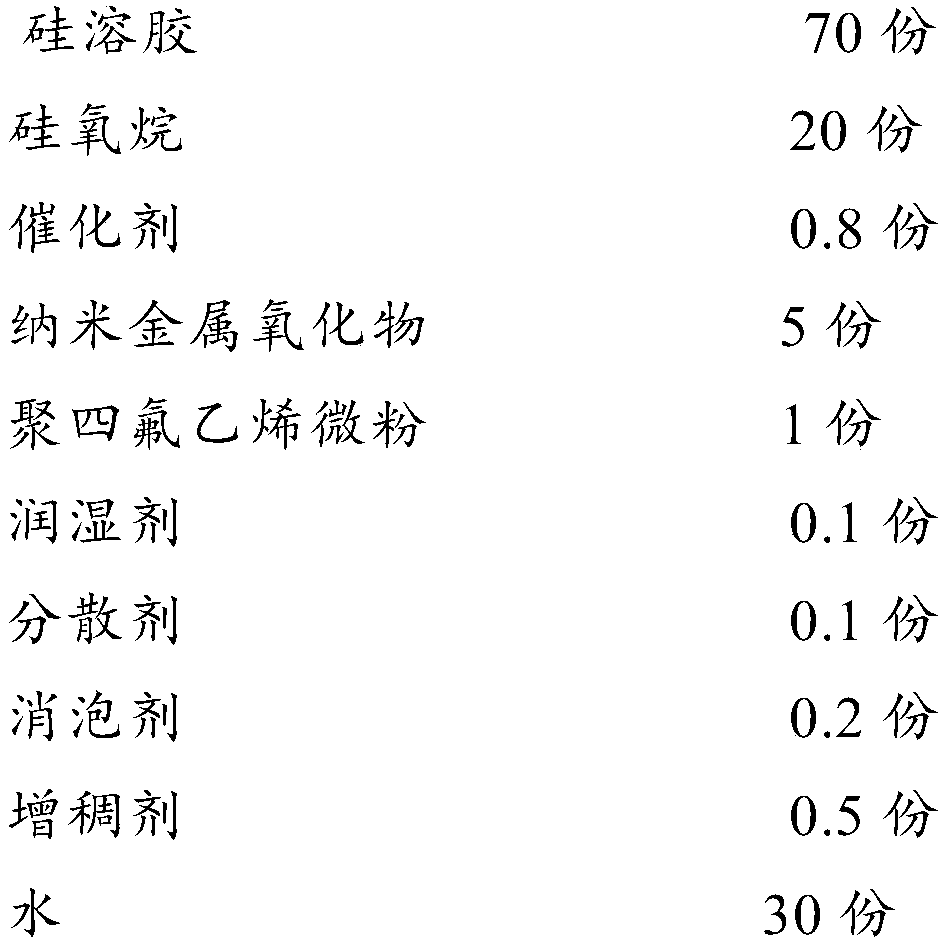

[0023] The color-changing and rewritable environmental protection paint is prepared by using the raw materials in the following weight ratio.

[0024]

[0025] Among them, the silica sol is alkaline silica sol, with a pH value of 10, an average particle size of 100nm, and a solid content of 50%; the siloxane is methyltriethoxysilane; the catalyst is hydrochloric acid with a mass fraction of 37%; the nanometer metal oxide is three Vanadium oxide (V 2 o 3 ); the particle size of polytetrafluoroethylene powder is 0.1 micron; the wetting agent is Silok8035; the dispersant is polyethylene glycol 400; the defoamer is Silok4920; the thickener is TT-935.

[0026] The specific preparation method is as follows:

[0027] (1) First weigh the siloxane, heat it to 50 degrees, add the catalyst and 5 parts of water mixture dropwise under stirring, continue stirring for 120 minutes after the dropwise addition, and cool to room temperature;

[0028] (2) Add the mixture prepared in (1) to ...

Embodiment 2

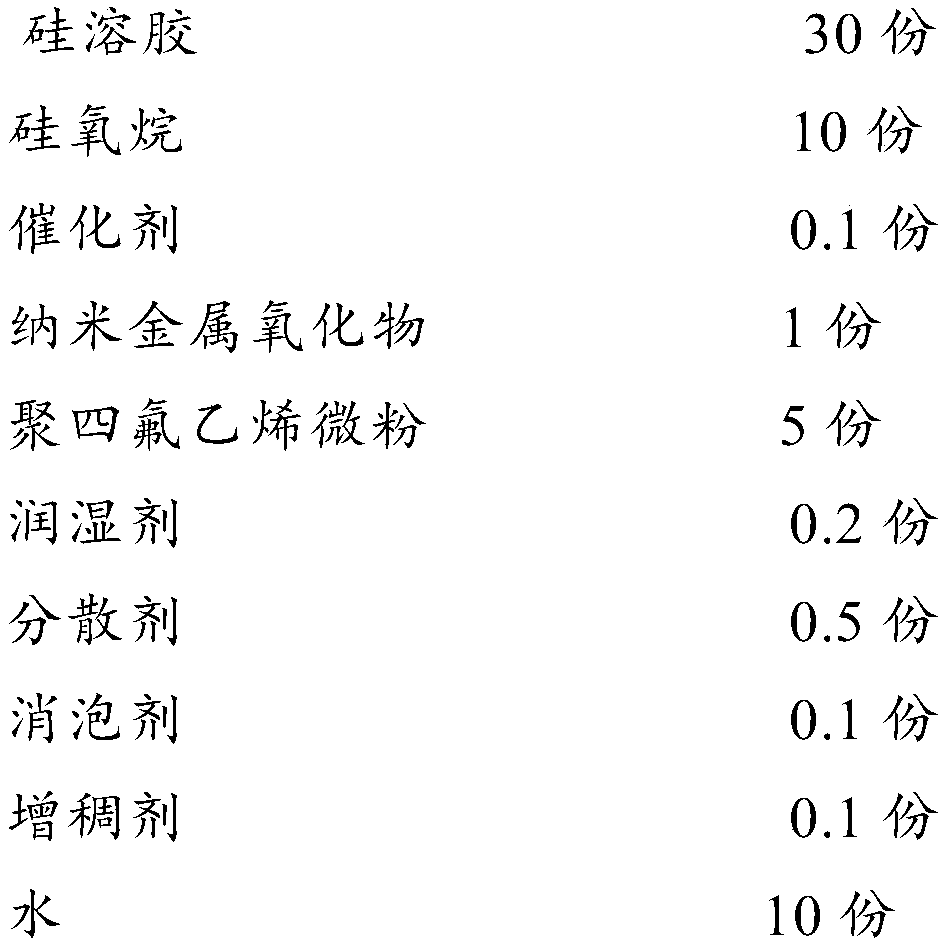

[0033] The color-changing and rewritable environmental protection paint is prepared by using the raw materials in the following weight ratio.

[0034]

[0035] Wherein the silica sol is an acidic silica sol, with a pH value of 5, an average particle diameter of 80nm, and a solid content of 30%; the siloxane is dimethyldimethoxysilane; the catalyst is acetic acid with a mass fraction of 36%; the nanometer metal oxide is Niobium dioxide (NbO 2 ) and tetratitanium heptoxide (Ti 4 o 7 ) mixture, the ratio of the two is 1:1; the particle size of polytetrafluoroethylene powder is 1 micron; the wetting agent is Silok8008; the dispersant is polydimethylsilicone oil; the defoamer is Silok4019; the thickener is RM-2020.

[0036] The specific preparation method is as follows:

[0037] (1) First weigh the siloxane, heat it to 40 degrees, add the catalyst and 5 parts of water mixture dropwise under stirring, continue stirring for 150 minutes after the dropwise addition, and cool to r...

Embodiment 3

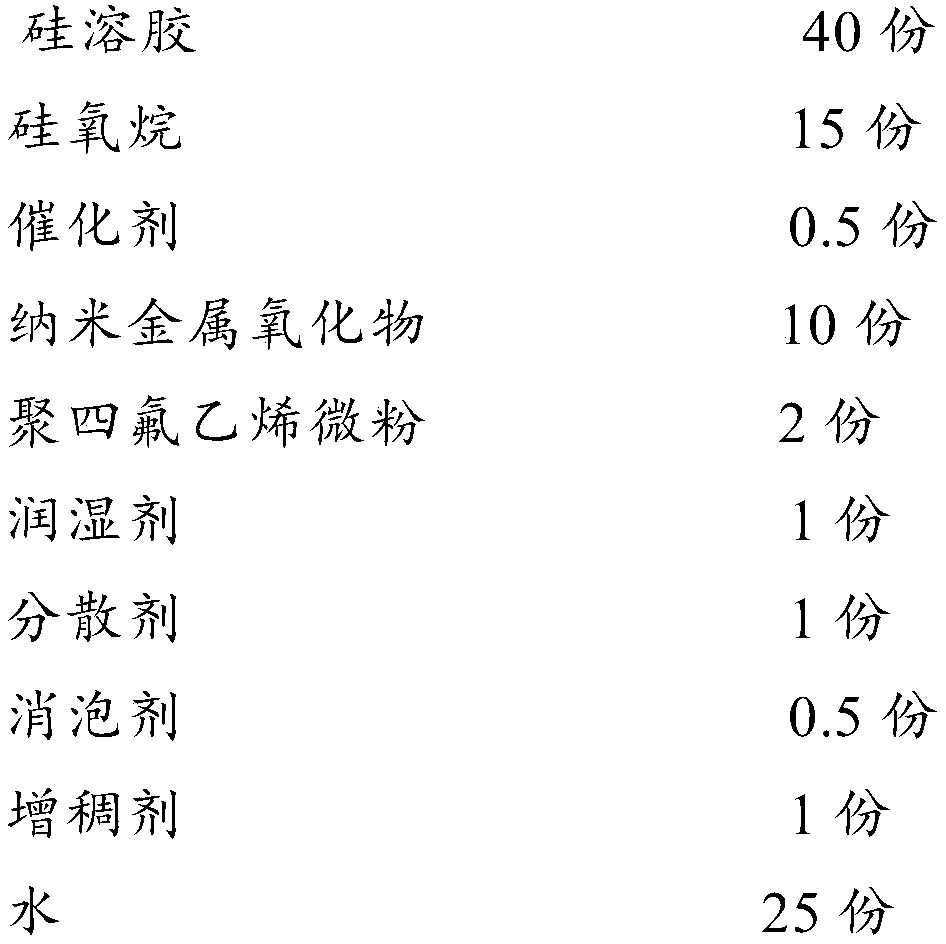

[0043] The color-changing and rewritable environmental protection paint is prepared by using the raw materials in the following weight ratio.

[0044]

[0045] Among them, the silica sol is alkaline silica sol, with a pH value of 9, an average particle size of 50nm, and a solid content of 40%; the siloxane is tetraethyl orthosilicate; the catalyst is sulfuric acid with a mass fraction of 98%; the nanometer metal oxide is manganese dioxide (MnO 2 ), vanadium dioxide (VO 2 ) and vanadium trioxide (V 2 o 3 ), the ratio of the three is 2:1:5; the wetting agent is Silok8008; the particle size of polytetrafluoroethylene powder is 5 microns; the dispersant is polyethylene glycol 600; the defoamer is Silok4920; the thickener is ASE-60.

[0046] The specific preparation method is as follows:

[0047] (1) First weigh the siloxane, heat it to 60 degrees, add the catalyst and 5 parts of water mixture dropwise under stirring, continue stirring for 80 minutes after the dropwise addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com