Preparation method for compound particle temporary plugging agent

A technology of composite particles and temporary plugging agent, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of no longer applicable, slow flowback, and reduced effect of plugging cracks, etc. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in combination with specific embodiments.

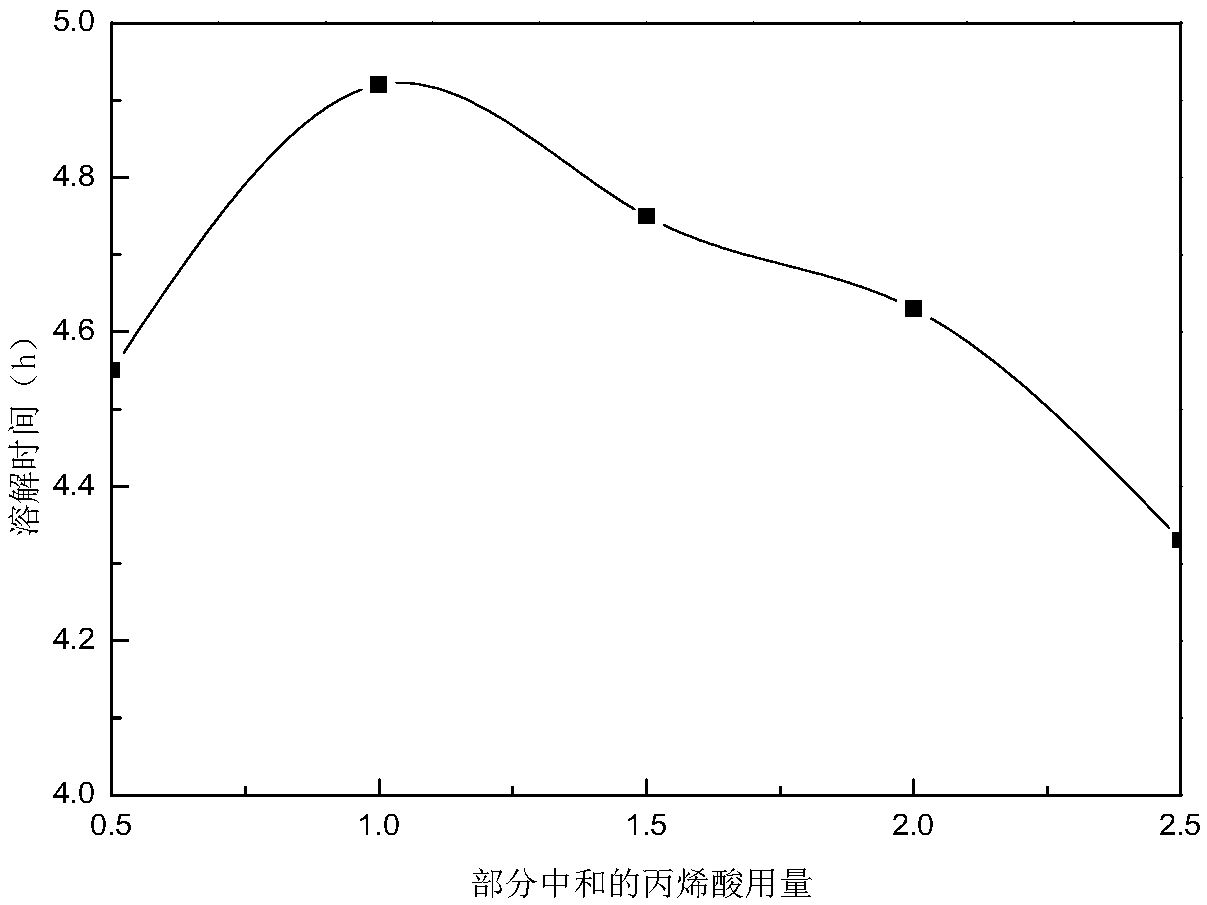

[0018] Dissolve potassium persulfate particles in 15ml of water, dissolve flake NaOH in 20ml of water, dilute acrylic acid with 10ml of water, put the beaker containing acrylic acid into the ice-water mixture and add the NaON solution drop by drop to the acrylic acid (dissolving NaOH exothermic , when the temperature is higher than 40 ° C, acrylic acid can self-polymerize, which can prevent its self-polymerization), forming a partially neutralized acrylic acid solution. The dissolution time reaches the maximum when the molar ratio of neutralized acrylic acid to acrylamide is 1:1. Considering the construction conditions and process conditions, it is most suitable when the molar ratio of partially neutralized acrylic acid to acrylamide is 1:1.

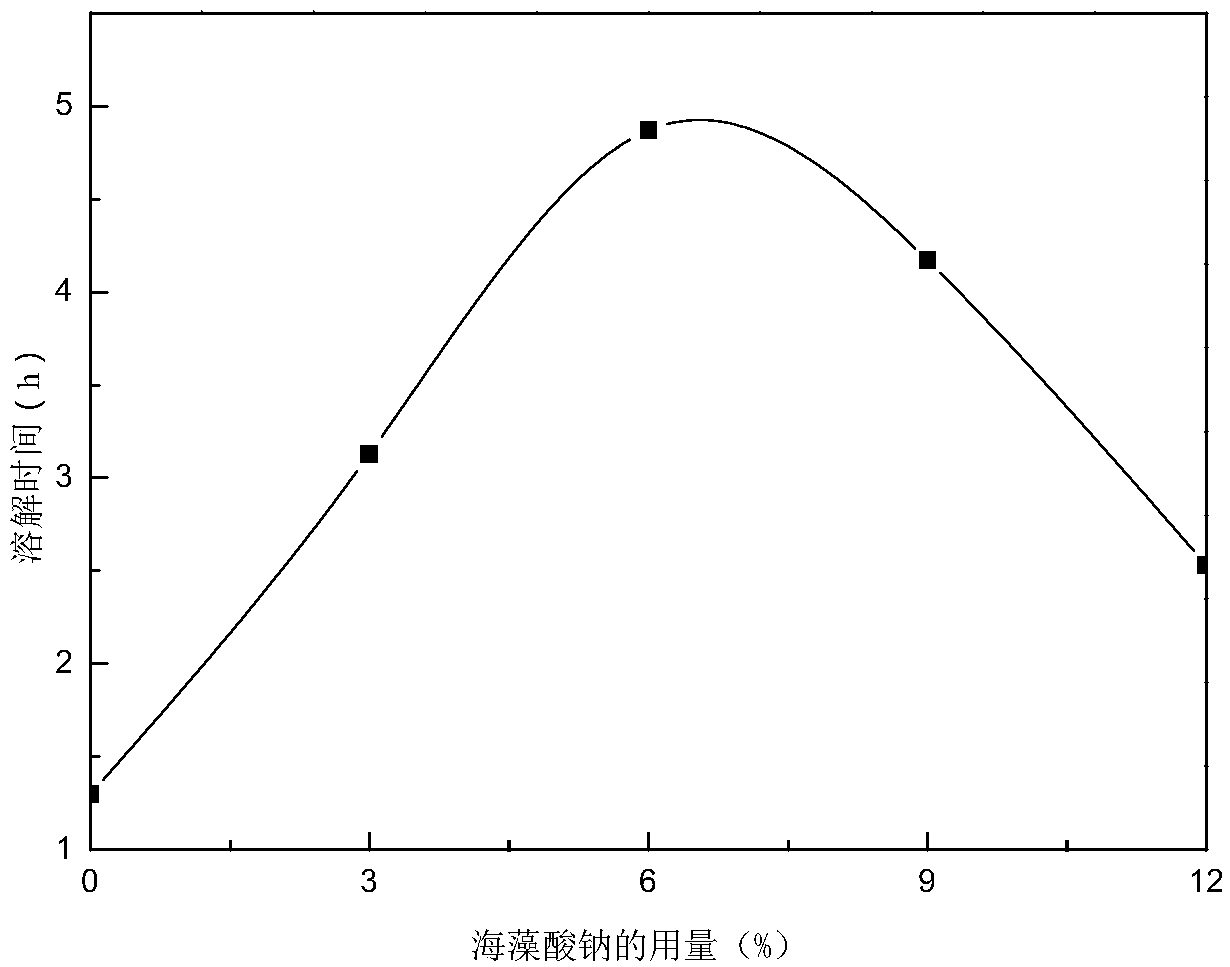

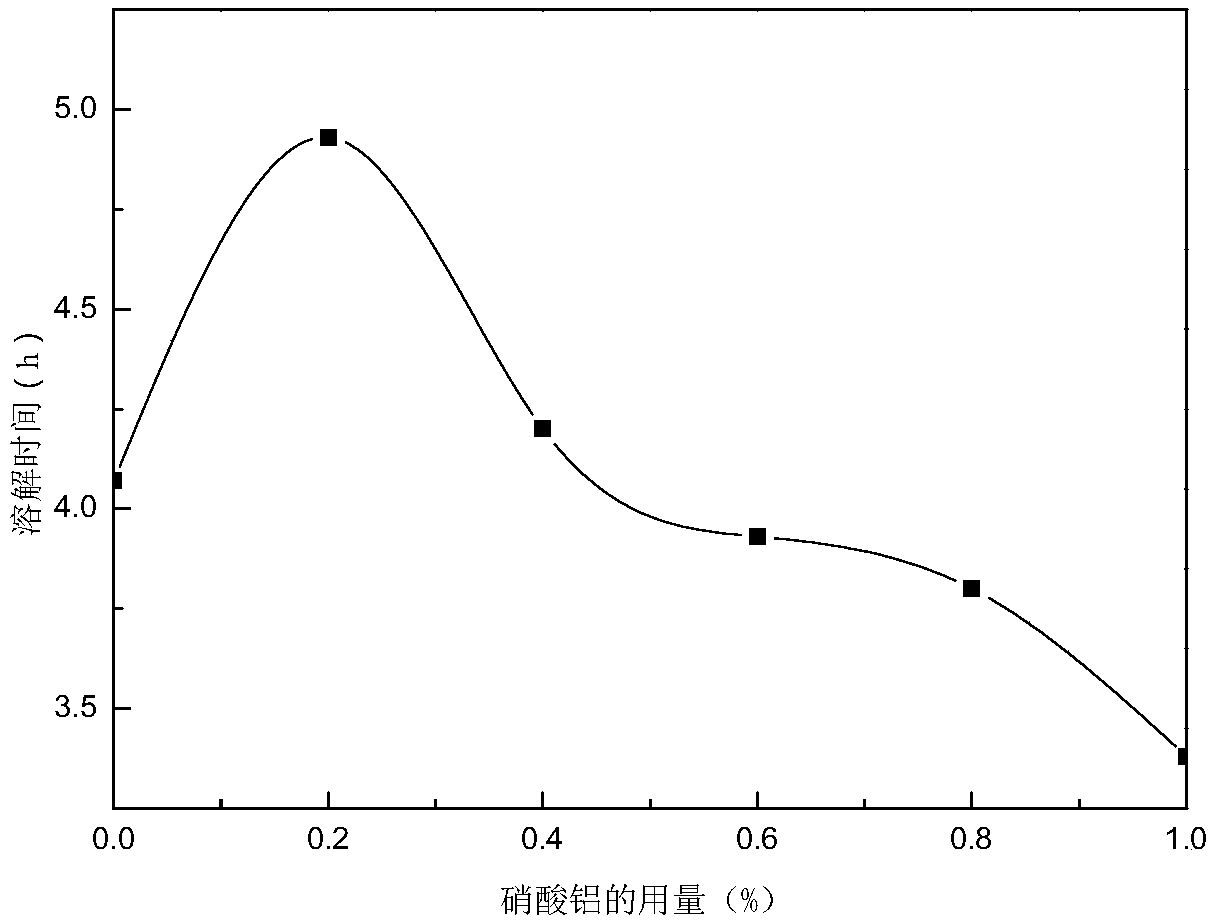

[0019] Then raise the temperature of the water bath to 75°C, and add 6g of acrylamide (AM), sodium alginate with 6% weight of acry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com