Clay pre-dispersed compound flame retardant filler and preparation method

A composite flame retardant and pre-dispersed technology, applied in fire-resistant coatings and other directions, can solve the problems of low efficiency of liquid battery fire extinguishing, and achieve the effect of flexible technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

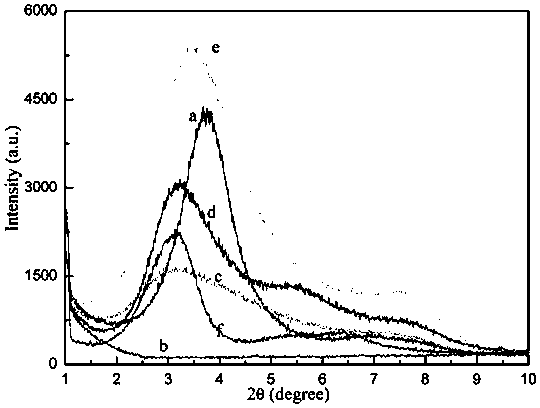

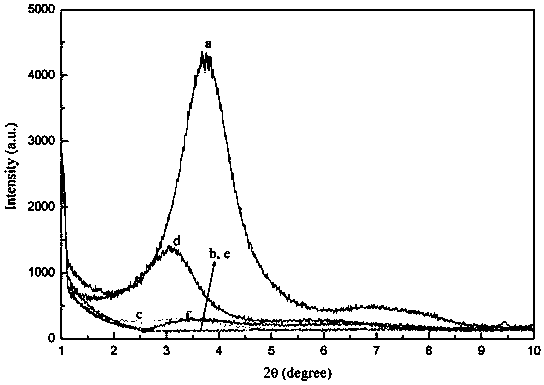

Image

Examples

Embodiment 1

[0027] Embodiment one: take decabromodiphenylethane as example:

[0028] The embodiment of the present invention provides a clay pre-dispersed composite flame retardant filler and its preparation method, the method comprising:

[0029] 1. Pretreatment with bromine series flame retardants

[0030] Dissolve and disperse 10 grams of bromine series flame retardant powder in chloroform, then add 15 mL of chlorosulfonic acid solution with a mass fraction of 5.0%, stir for 30 minutes, and then separate the modified flame retardant in the chloroform solution, The powdery modified flame retardant is obtained by freezing or spray drying.

[0031] 2. Clay treatment

[0032] Disperse 10g of powdered modified flame retardant with 20mL THF tetrahydrofuran solution to form an emulsion; disperse 20g of clay in 20mL THF and stir for 24 hours; then mix the two according to the volume ratio of 1:1, and stir for 24 hours. The precipitate was separated by centrifugation. The precipitate is fre...

Embodiment 2

[0034] Embodiment two: decabromodiphenyl ether is an example:

[0035] The embodiment of the present invention provides a clay pre-dispersed composite flame retardant filler and its preparation method, the method comprising:

[0036] 1. Pretreatment with bromine series flame retardants

[0037] Dissolve and disperse 10 grams of bromine series flame retardant powder in chloroform, then add 150 mL of chlorosulfonic acid solution with a mass fraction of 35.0%, stir for 60 minutes, and then separate the modified flame retardant in the chloroform solution, The powdery modified flame retardant is obtained by freezing or spray drying.

[0038] 2. Clay treatment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com