Method for in-situ preparation of biodiesel from Jiangxi gardenia as raw material in deep eutectic solvent/n-hexane system through ultrasonic assistance

A technology of deep eutectic solvent and biodiesel, which is applied in the fields of biofuel, fat oil/fat production, fuel, etc., can solve the problems of difficult separation, complicated process and high cost, and achieve the effect of reducing cost, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

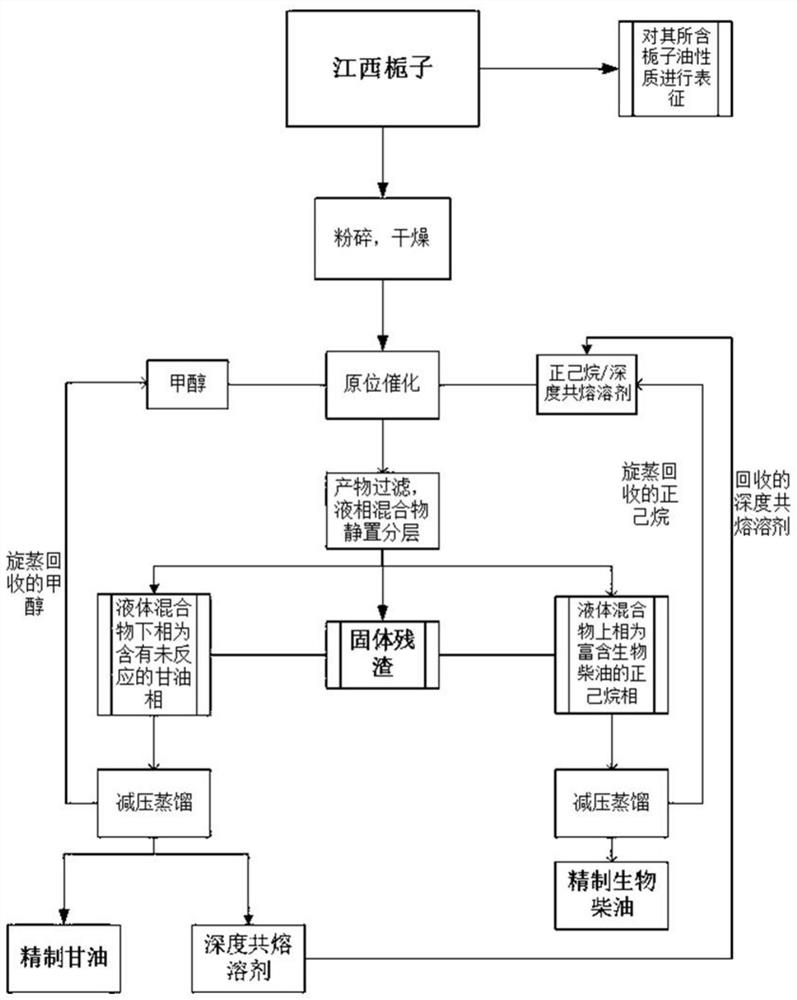

Method used

Image

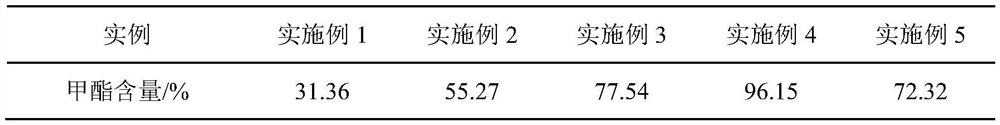

Examples

Embodiment 1

[0047] The extraction-transesterification coupling in-situ preparation of biodiesel in a deep eutectic solvent / n-hexane system using Gardenia jasminoides Jiangxi as raw materials includes the following steps:

[0048] (1) The Jiangxi Gardenia raw material is sterilized by autoclaving, washed with deionized water, dried in vacuum, pulverized by a pulverizer to obtain Jiangxi Gardenia powder raw material;

[0049] (2) In a 250ML round-bottomed flask, add 30g of Jiangxi Gardenia powder with an alcohol-to-oil ratio of 10:1, 180ml of deep eutectic solvent / n-hexane mixed solution, including 2.7g of DES. After installing the condensing device, put it into the ultrasonic reactor;

[0050] (3) Start the ultrasonic reactor heating device and set the reaction temperature to 30°C. After reaching the set value, start the ultrasonic switch and start to react;

[0051] (4) The reaction is terminated, wait for the flask to be cooled to normal temperature, unload the condensing reflux device...

Embodiment 2

[0055] The extraction-transesterification coupling in-situ preparation of biodiesel in a deep eutectic solvent / n-hexane system using Gardenia jasminoides Jiangxi as raw materials includes the following steps:

[0056] (1) The Jiangxi Gardenia raw material is sterilized by autoclaving, washed with deionized water, dried in vacuum, pulverized by a pulverizer to obtain Jiangxi Gardenia powder raw material

[0057] (2) In a 250ML round bottom flask, add 30g of Jiangxi Gardenia powder, alcohol-to-oil ratio 10:1, 180ml deep eutectic solvent / n-hexane mixed solution, including 2.7g of DES. After installing the condensing device, put it into the ultrasonic reactor;

[0058] (3) Start the ultrasonic reactor heating device and set the reaction temperature to 40°C. After reaching the set value, start the ultrasonic switch and start to react;

[0059] (4) The reaction is terminated, wait for the flask to be cooled to normal temperature, unload the condensing reflux device, take out the s...

Embodiment 3

[0063] The extraction-transesterification coupling in-situ preparation of biodiesel in a deep eutectic solvent / n-hexane system using Gardenia jasminoides Jiangxi as raw materials includes the following steps:

[0064] (1) The Jiangxi Gardenia raw material is sterilized by autoclaving, washed with deionized water, dried in vacuum, pulverized by a pulverizer to obtain Jiangxi Gardenia powder raw material;

[0065] (2) In a 250ML round bottom flask, add 30g of Jiangxi gardenia powder, the alcohol-to-oil ratio is 10:1, 180ml deep eutectic solvent / n-hexane mixed solution, of which DES 2.7g. After installing the condensing device, put it into the ultrasonic reactor;

[0066] (3) Start the ultrasonic reactor heating device and set the reaction temperature to 50°C. After reaching the set value, start the ultrasonic switch and start to react;

[0067] (4) The reaction is terminated, wait for the flask to be cooled to normal temperature, unload the condensing reflux device, take out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com