Method for extracting vanadium from vanadium-containing stone coal ore

A stone coal mine, stone coal vanadium technology, applied in the direction of process efficiency improvement, sulfur preparation/purification, etc., can solve the problems of low vanadium recovery rate, environmental pollution, etc., and achieve the goal of shortening production time, reducing costs, and saving production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A high-efficiency desulfurization pre-enrichment method for vanadium-containing stone coal, comprising the following steps:

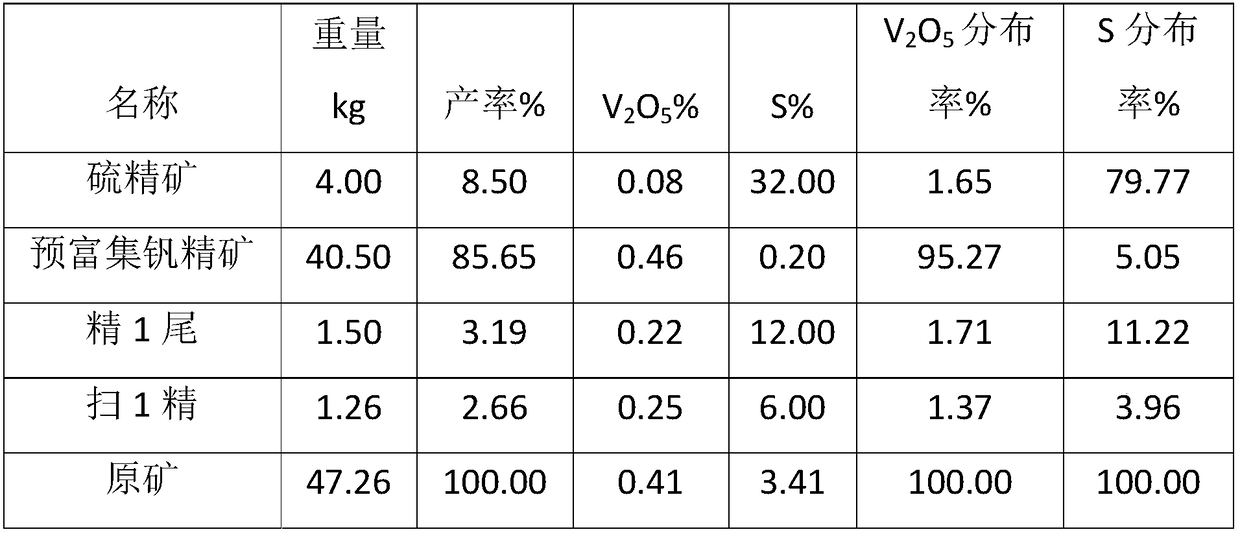

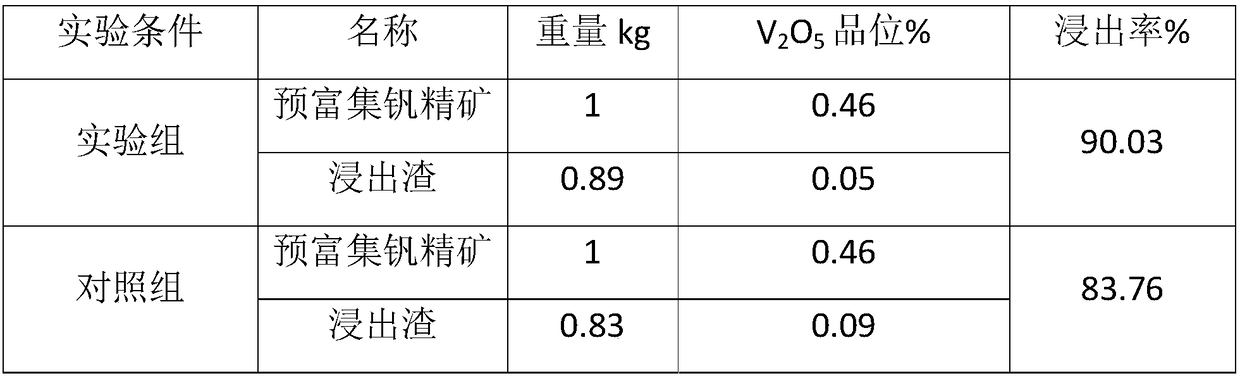

[0033] A stone coal mine in Sichuan, the appearance is uneven in thickness, dark brown, V 2 o 5 The average content is about 0.353%. According to the method of the present invention, 68.86kg of ore is processed, crushed, and then sieved out +50mm, 50-30mm, 30-20mm, 20-10mm, 10mm-2mm, and -2mm with a dry sieve. Grain fractions, the weight of each fraction and where V 2 o 5 The content and distribution rate were detected, and the experimental results are shown in Table 1. Heat the remaining stone coal ore in a vacuum sintering furnace at a heating temperature of 680-700°C and a heating time of 5 minutes. During the heating process, sulfur element is recovered; the heated stone coal ore is dry-ground with a ball mill until it is completely passed 100-mesh sieve; then use a dry magnetic separator to carry out magnetic separation treatment. Magnet...

Embodiment 2

[0045] A high-efficiency desulfurization pre-enrichment method for vanadium-containing stone coal, comprising the following steps:

[0046] A stone coal mine in Sichuan, the appearance is uneven in thickness, dark brown, V 2 o 5 The average content is about 1.2%. According to the method of the present invention, 70.12kg of ore is processed, crushed, and then sieved out +50mm, 50-30mm, 30-20mm, 20-10mm, 10mm-2mm, and -2mm thick with a dry sieve. Grain fractions, the weight of each fraction and where V 2 o 5 The content and distribution rate were detected, and the experimental results are shown in Table 4. Heat the remaining stone coal ore in a vacuum sintering furnace at a heating temperature of 380-460°C and a heating time of 6 minutes. During the heating process, simple sulfur is recovered; the heated stone coal ore is dry-ground with a rod mill until All pass through a 60-mesh sieve; then dry-type magnetic separator is used for magnetic separation treatment. The magnetic...

Embodiment 3

[0059] A high-efficiency desulfurization pre-enrichment method for vanadium-containing stone coal, comprising the following steps:

[0060] A stone coal mine in Sichuan, the appearance is uneven in thickness, dark brown, V 2 o 5 The average content is about 0.895%. According to the method of the present invention, 66.54kg of ore is processed, crushed, and then sieved out +50mm, 50-30mm, 30-20mm, 20-10mm, 10mm-2mm, and -2mm with a dry sieve. Grain fractions, the weight of each fraction and where V 2 o 5 The content and distribution rate were detected, and the experimental results are shown in Table 7. Heat the remaining stone coal ore in a vacuum sintering furnace, the heating temperature is 1750-1856°C, and the heating time is 2 minutes. During the heating process, sulfur element is recovered; the heated stone coal ore is dry-ground with a ball mill until it is completely passed 100-mesh sieve; then use a dry magnetic separator to carry out magnetic separation treatment. M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com