A composite coating material for improving the high temperature self-lubricating wear resistance of ti6al4v alloy and its preparation method

A high-temperature self-lubricating, composite coating technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of difficulty in meeting practical application requirements, limited improvement in wear resistance of Ti6Al4V alloy substrates, etc. The effect of self-lubricating wear resistance and hardness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides the preparation method of described composite coating material, comprises the steps:

[0044] mixing the alloy powder and the binder, prefabricating on the surface of the Ti6Al4V alloy, drying, and then obtaining the composite coating material through a laser cladding process;

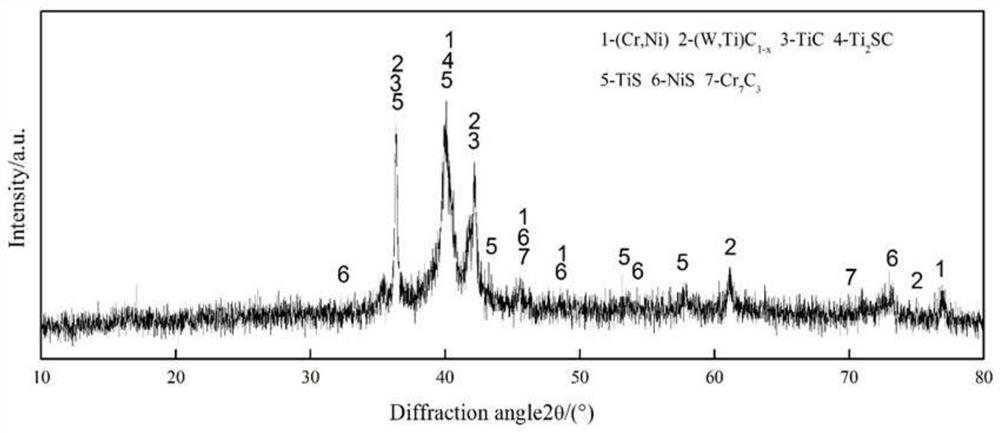

[0045] The alloy powder includes: TiC16-17wt%, WS 2 22~25wt%, the balance is Ni60.

[0046] The output power of the laser cladding is preferably 1.5-2kW, the output rectangular spot of the laser beam is preferably (3-5)mm×(4-6)mm, the scanning speed is preferably 4-6mm / s, and the energy density is preferably 80 ~100J / mm 2 . More preferably, the output power of the laser cladding is 1.8kW, the output rectangular spot of the laser beam is 4mm×5mm, the scanning speed is 5mm / s, and the energy density is 90J / mm 2 . The present invention has no limitation on the mixing method of the alloy powder and the binder, and it is preferably carried out by using a ball m...

Embodiment 1

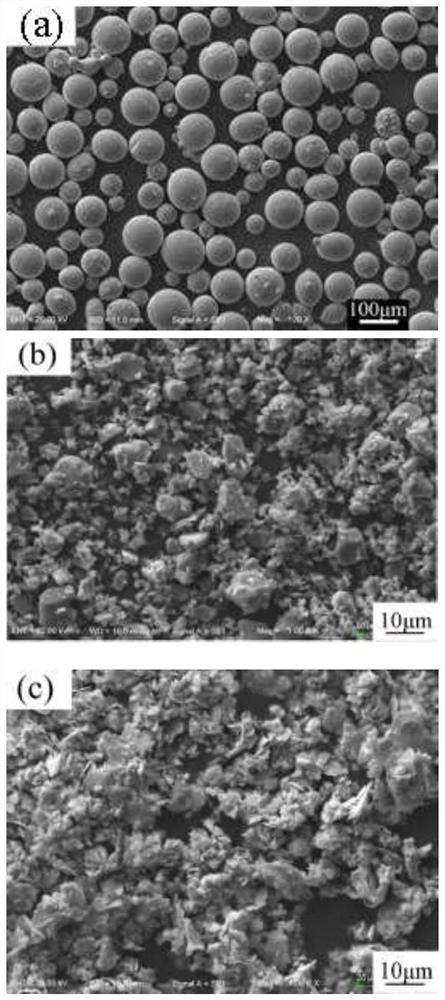

[0050] 1. 60wt% Ni60 (average particle size 140 μm), 16.8wt% TiC (average particle size 2 μm) and 23.2wt% WS 2 (average particle size 1 μm) was added to a QM-3SP04 ball mill for ball milling for 12 hours, and then dried to obtain alloy powder.

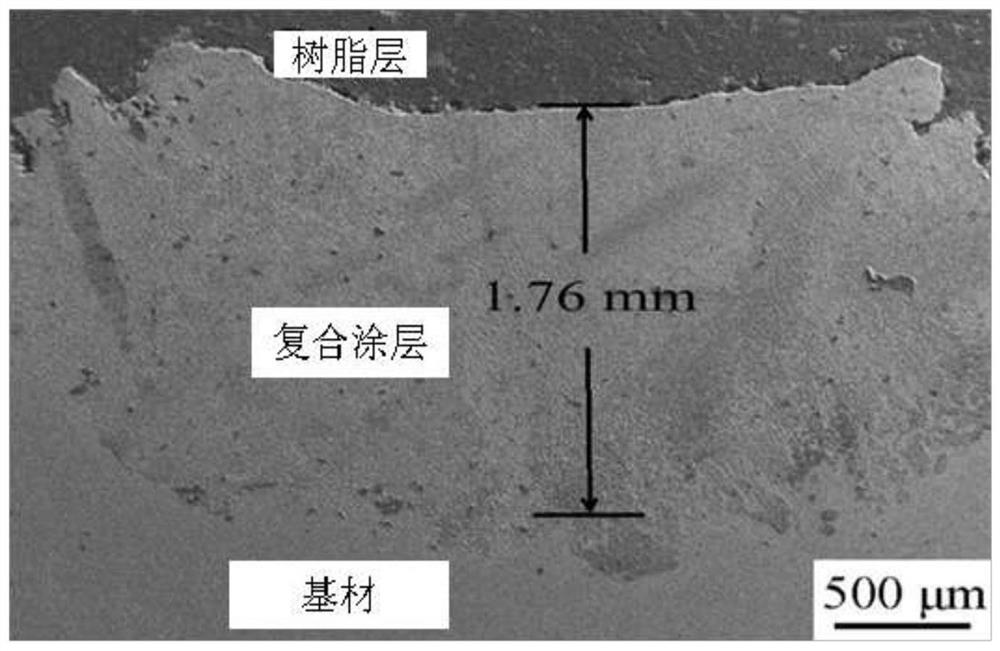

[0051] 2. Mix the above alloy powder with methylcellulose solution, stir until viscous, and then coat the surface of Ti6Al4V alloy with a coating thickness of 1.8mm, and then keep it in a drying oven at 120°C for 2h.

[0052] 3. Use DLS-980.10-3000C semiconductor laser to scan the surface of the preset alloy powder, adjust the output power to 1.8kW, the output rectangular spot of the laser beam is 4mm×5mm, the scanning speed is 5mm / s, and the energy density is 90J / mm 2 , forming a composite coating material on the surface of Ti6Al4V alloy.

Embodiment 2

[0054] 1. 60wt% Ni60 (average particle size 140 μm), 16wt% TiC (average particle size 2 μm) and 24wt% WS 2 (average particle size 1 μm) was added to a QM-3SP04 ball mill for ball milling for 12 hours, and then dried to obtain alloy powder.

[0055] 2. Mix the above alloy powder with methylcellulose solution, stir until viscous, and then coat the surface of Ti6Al4V alloy with a coating thickness of 1.8mm, and then keep it in a drying oven at 120°C for 2h.

[0056] 3. Use DLS-980.10-3000C semiconductor laser to scan the surface of the preset alloy powder, adjust the output power to 1.5kW, the output rectangular spot of the laser beam is 3mm×4mm, the scanning speed is 4mm / s, and the energy density is 80J / mm 2 , forming a composite coating material on the surface of Ti6Al4V alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com