Measuring method of laser beam quality factor M2 and measuring device thereof

A technology of beam quality and measurement method, which is applied in the field of lasers, can solve the problems of affecting measurement efficiency and measurement accuracy, taking a long time, and heavy workload, and achieves the effects of fast and simple measurement, compact structure, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

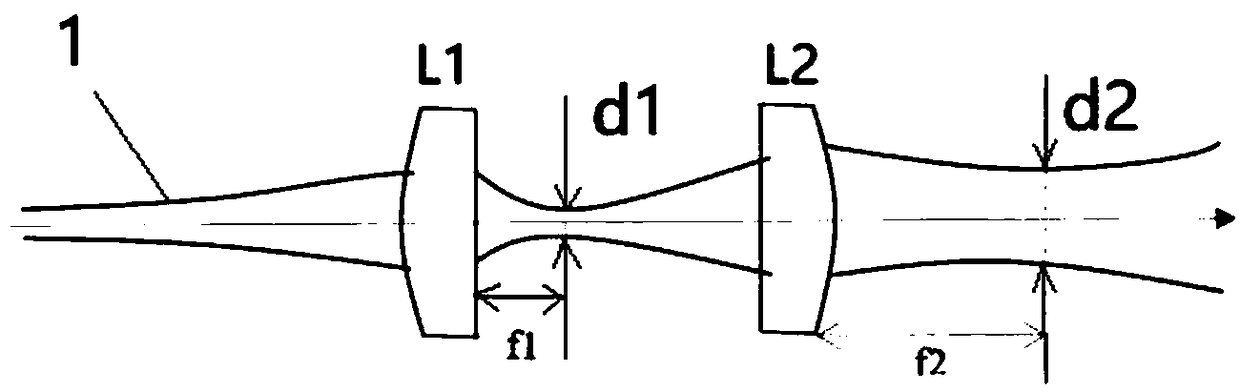

[0045] A kind of measurement method of laser beam quality factor M2, see figure 1 , including the following steps:

[0046] Focus the Gaussian beam of the laser to be tested through a positive lens L1 with a focal length of f1;

[0047] Move the CCD back and forth to find the minimum spot position of the focused Gaussian beam;

[0048] Measure and record the minimum spot diameter d1 at the minimum spot position to obtain the beam waist diameter d=d of the Gaussian beam 1 ;

[0049] A focusing lens L2 with a focal length of f2 is arranged behind the focused Gaussian beam, and then the focal spot diameter d2 is measured at the focal plane position of the focusing lens L2, then the divergence angle θ of the Gaussian beam is passed by the following formula Get:

[0050]

[0051] Then the M2 factor can be obtained by the following formula:

[0052]

[0053] Among them, λ is the wavelength of the Gaussian beam of the laser to be tested, and π is the circumference ratio. ...

Embodiment 2

[0056] A method for measuring the laser beam quality factor M2 is similar to Embodiment 1, except that the positive lens L1 is a plano-convex lens; the plane of the positive lens L1 is the incident surface of the light beam, and the convex surface is the surface of the light beam. exit surface.

[0057] In this way, the positive lens L1 is a plano-convex lens, and the distance from the convex surface to the focal point is equal to the back focal length BFL (Back Focus Length, back focal length) and the effective focal length EFL (Effective Focus Length), which is convenient for handling.

[0058] In another specific embodiment, the diameter of the positive lens L1 is larger than the diameter of the incident light spot of the laser.

[0059] In another specific embodiment, the focusing lens L2 is a plano-convex lens, the plane of the focusing lens L2 is the incident surface of the light beam, and the convex surface is the outgoing surface of the light beam.

[0060] In another...

Embodiment 3

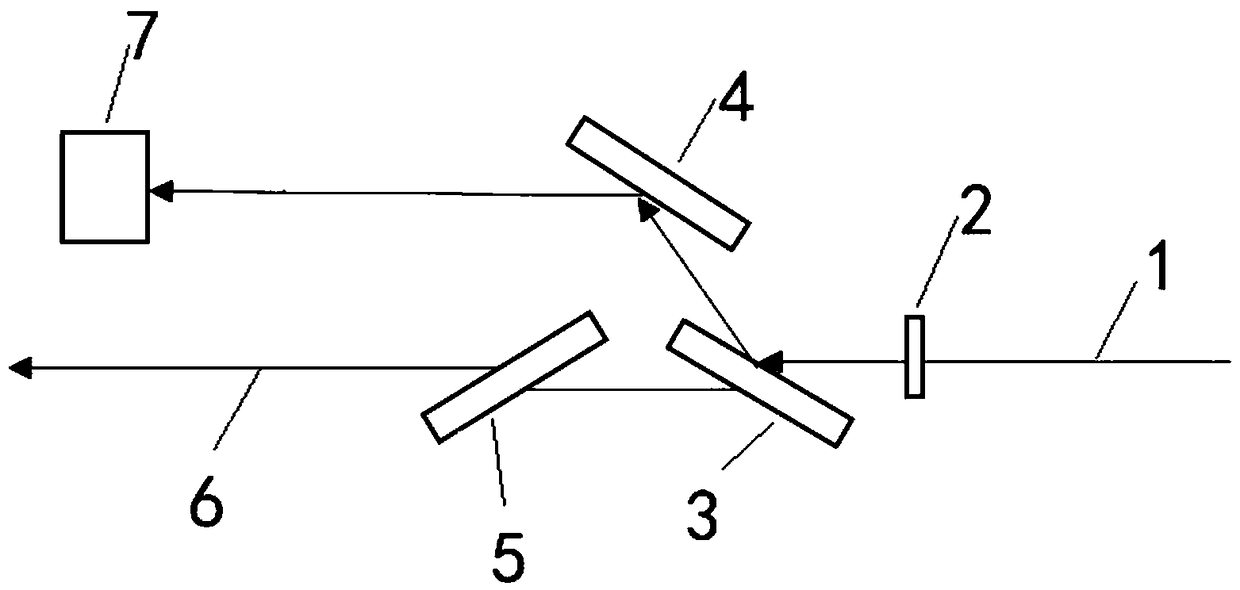

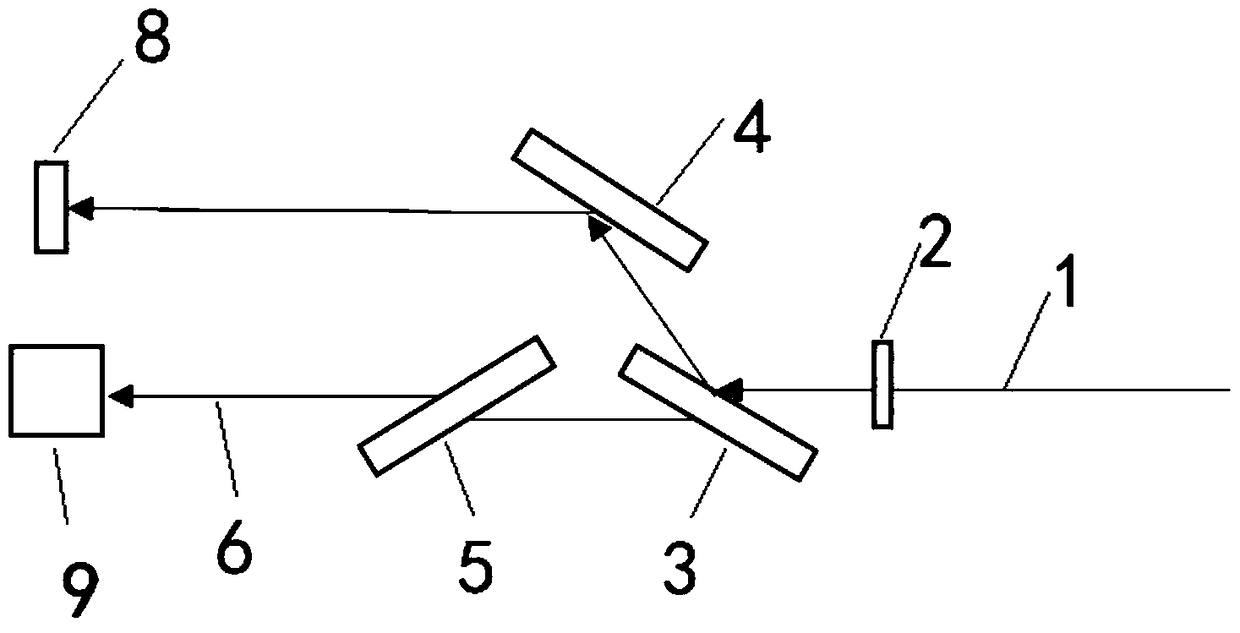

[0064] A measuring device for a measuring method of a laser beam quality factor M2, the measuring device for a measuring method for a laser beam quality factor M2 includes an optical path component, a measuring component, and an attenuation component;

[0065] see figure 2 , the optical path assembly includes a half-wave plate 2 and a first polarizer 3 arranged in sequence along the optical axis of the incident light beam 1, the first polarizer 3 is arranged to be inclined from left to right, and the reflection of the first polarizer 3 A second polarizer 4 is arranged on the optical axis of the light beam, and the second polarizer 4 is arranged to be inclined from left to right. The second polarizer 4 is located above the first polarizer 3. The incident beam 1, the first polarizer The reflected beam of 3 and the reflected beam of the second polarizer 4 form a "Z" shape structure, and the incident beam 1 and the reflected beam of the second polarizer 4 are parallel; the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com