Preparation method for soluble sugar frame rice protein

A rice protein and soluble technology, applied in protein food processing, vegetable protein processing, protein food ingredients, etc., can solve the problems of food safety, nutrient loss, protein hydrolysis easily, etc., to improve productivity and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

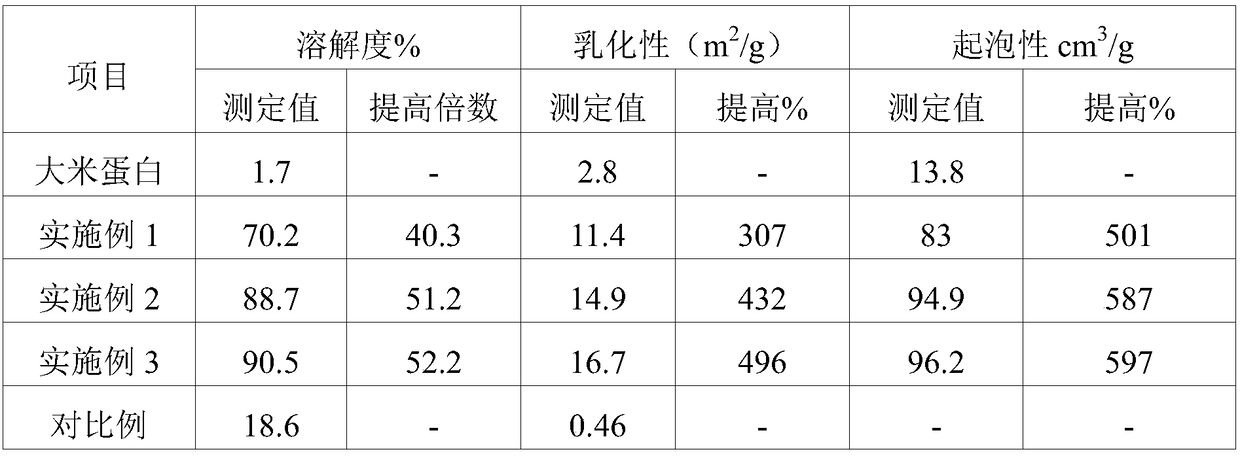

Embodiment 1

[0040] (1) Alkali dispersion: disperse 1000g of rice protein and 50g of carboxymethyl cellulose in 10L of water, stir and mix well, and adjust the pH of the above protein-polysaccharide dispersion to 10.0 with NaOH solution;

[0041] (2) Sugar shelf: Stir the feed solution obtained in step (1) for 60 minutes at a speed of 600 r / min, so that the binding sites of the two component structures are fully exposed and structural connections occur;

[0042] (3) Acid neutralization: adjust the pH of the feed liquid obtained in step (2) to 6.5 with HCl;

[0043] (4) centrifugation: centrifuge the feed liquid obtained in step (3) at 4000g for 5min, and get the supernatant;

[0044] (5) Drying: The supernatant obtained in step (4) is dialyzed and freeze-dried to obtain a soluble sugar shelf rice protein product.

Embodiment 2

[0046] (1) Alkali dispersion: disperse 1000g of rice protein, 200g of sodium carboxymethylcellulose, and 300g of pectin in 10L of water, stir and mix well, and adjust the pH of the dispersion to 11.0 with NaOH solution;

[0047] (2) Sugar rack: Stir the feed solution obtained in step (1) for 90 minutes at a speed of 1500 r / min, so that the binding sites of various component structures are fully exposed and structural connections occur;

[0048] (3) Acid neutralization: adjust the pH of the feed liquid obtained in step (2) to 7.0 with HCl;

[0049] (4) centrifugation: the feed liquid obtained in step (3) is centrifuged at 7000g for 10min, and the supernatant is taken;

[0050] (5) Drying: The supernatant obtained in step (4) is dialyzed and freeze-dried to obtain a soluble sugar shelf rice protein product.

Embodiment 3

[0052] (1) Alkali dispersion: Disperse 1000g of rice protein, 300g of pectin, 200g of gum arabic, and 500g of sodium alginate in 10L of water, stir and mix well, and adjust the pH of the dispersion to 12.0 with NaOH solution;

[0053] (2) Sugar rack: Stir the feed solution obtained in step (1) for 30 minutes at a speed of 2000 r / min, so that the binding sites of various component structures are fully exposed and structural connections occur;

[0054] (3) Acid neutralization: adjust the pH of the feed liquid obtained in step (2) to 8.0 with HCl;

[0055] (4) centrifugation: centrifuge the feed liquid obtained in step (3) at 10000g for 20min, and get the supernatant;

[0056] (5) Drying: The supernatant obtained in step (4) is dialyzed and freeze-dried to obtain a soluble sugar shelf rice protein product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com