Patents

Literature

30results about How to "To achieve the modified effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct-casting type anti-track agent and preparation method

ActiveCN102585522AImprove plasticityHigh modulus at room temperatureBuilding insulationsWaxPolyester

The invention discloses a direct-casting type anti-track agent, which is formed by the following components by weight in mixing mode: 20 to 40 parts of regenerative polyolefine plastic, 10 to 20 parts of regenerative polyester plastic, 2 to 10 parts of regenerative wax, 2 to 10 parts of organic powder body with small particle size and 5 to 10 parts of gilsonite. A preparation method of the direct-casting type anti-crack agent and a method for preparing asphalt mixture by adopting the direct-casting type anti-crack agent are further disclosed. Particles of the direct-casting type anti-crack agent can be directly cast in hot aggregate on construction sites to be mixed with the hot aggregate in drying mode, intermittent construction can be conducted, and the direct-casting type anti-track agent lowers or reduces probability of separation of modified asphalt in the cooling, transporting and storing processes, and break through limit and restraint brought by continuous production and construction.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

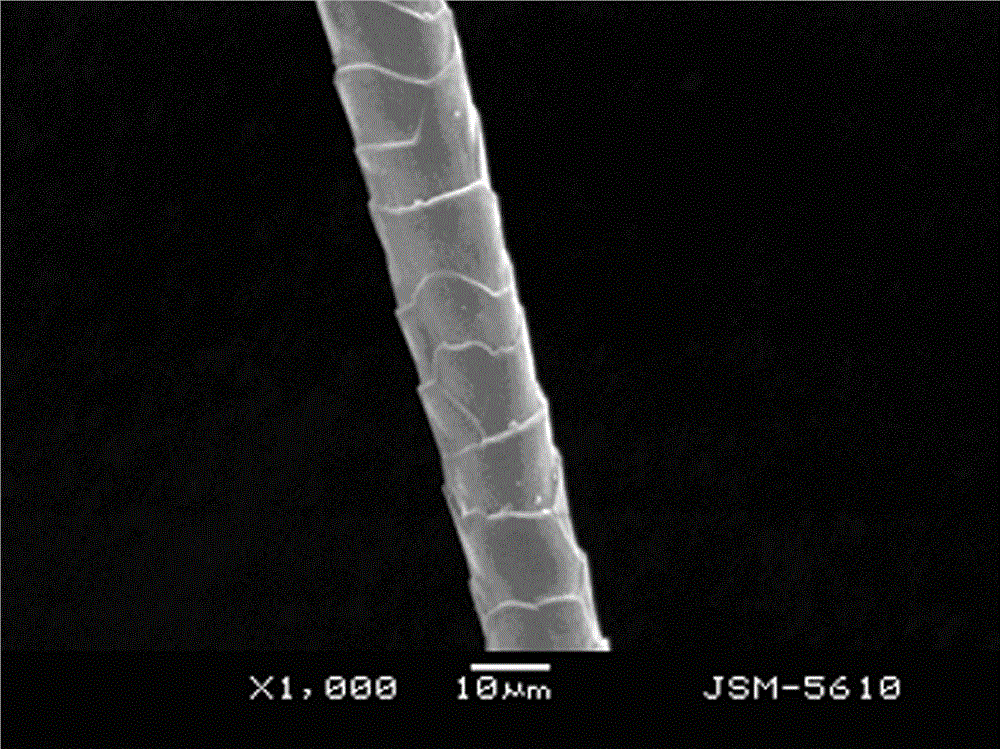

Surface modification method for wool

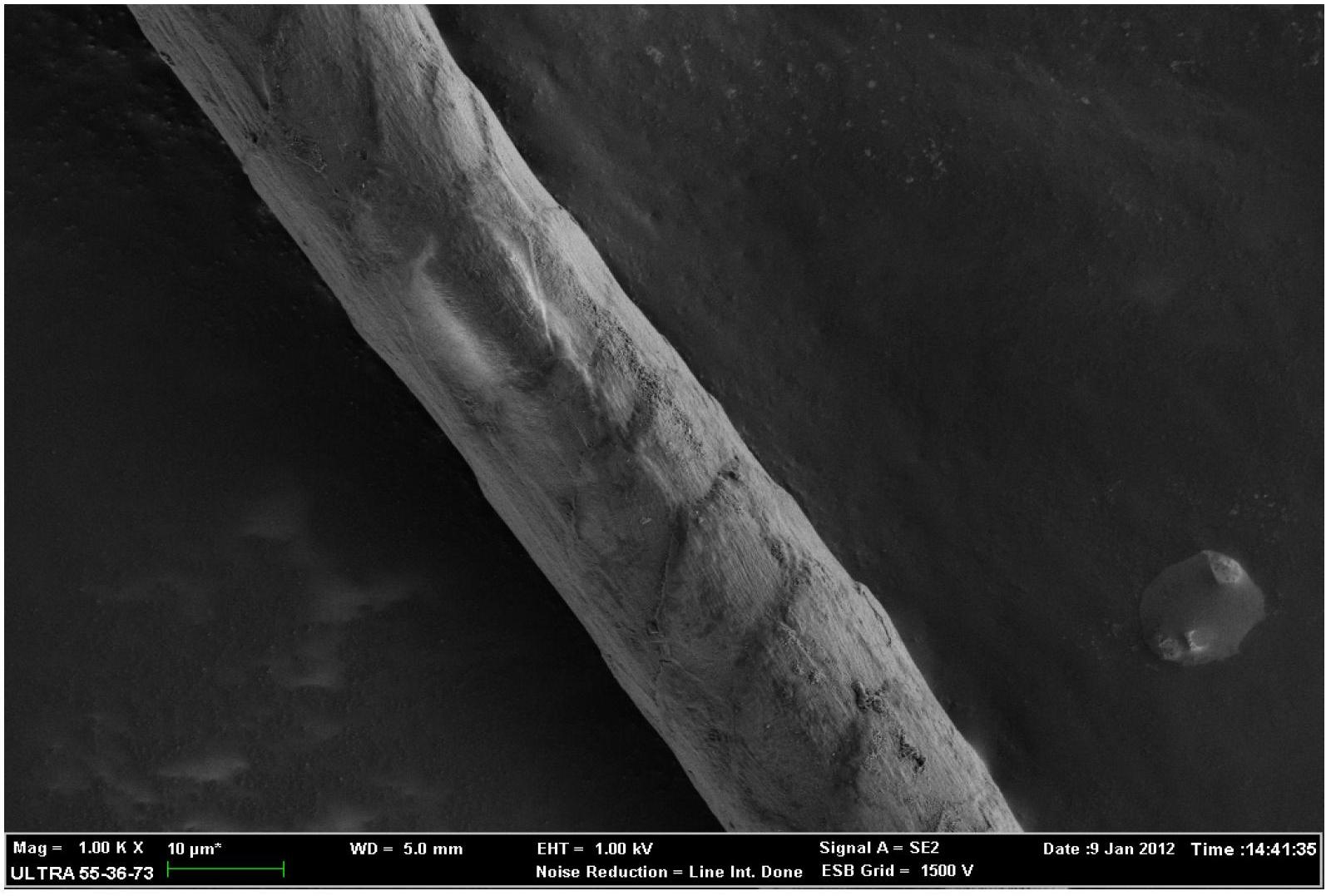

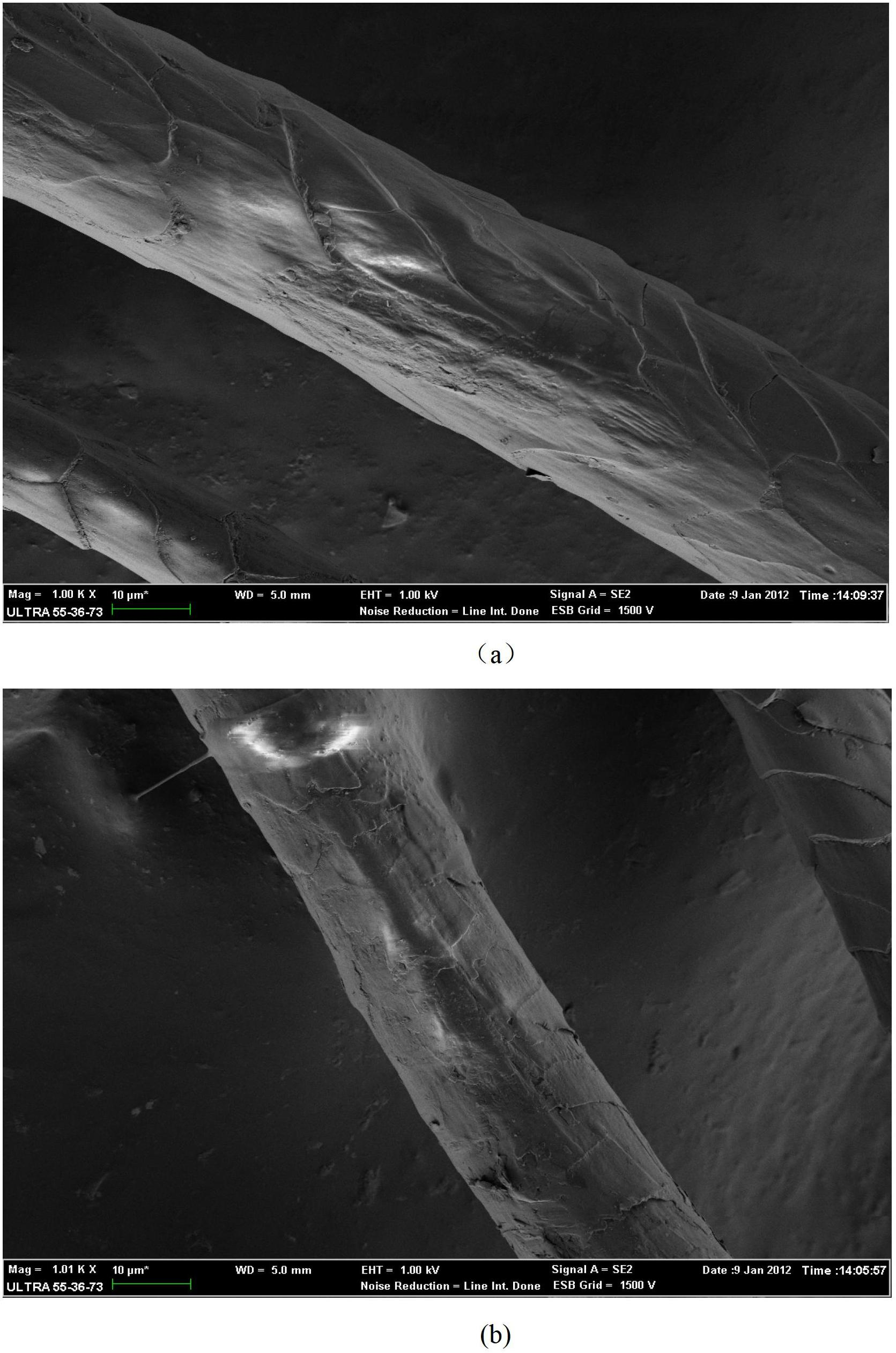

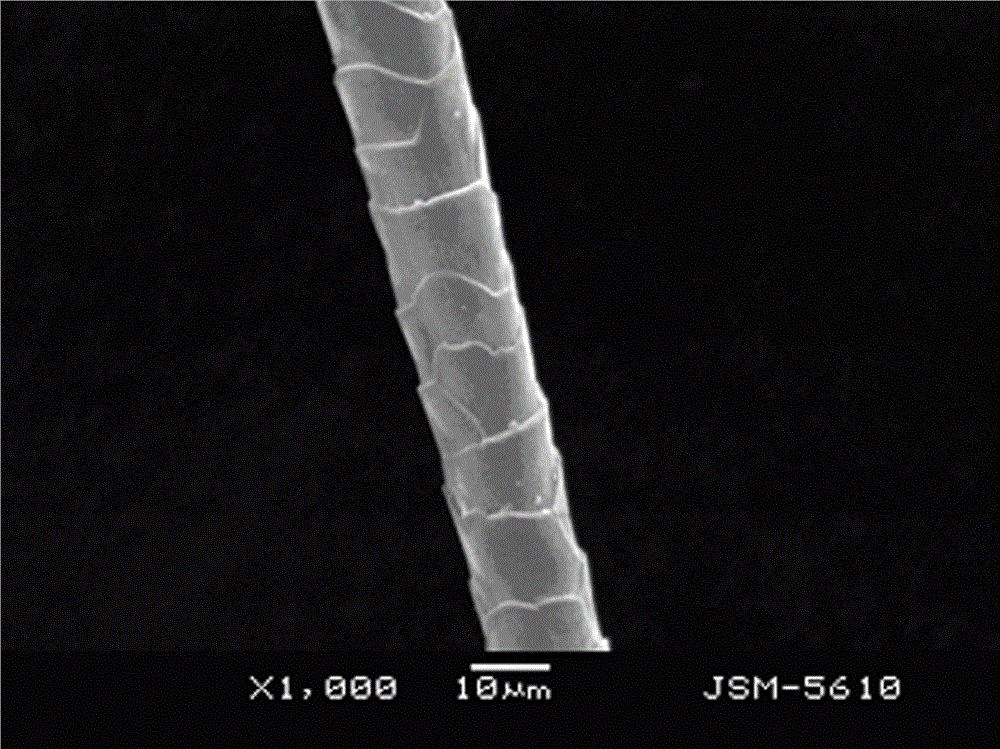

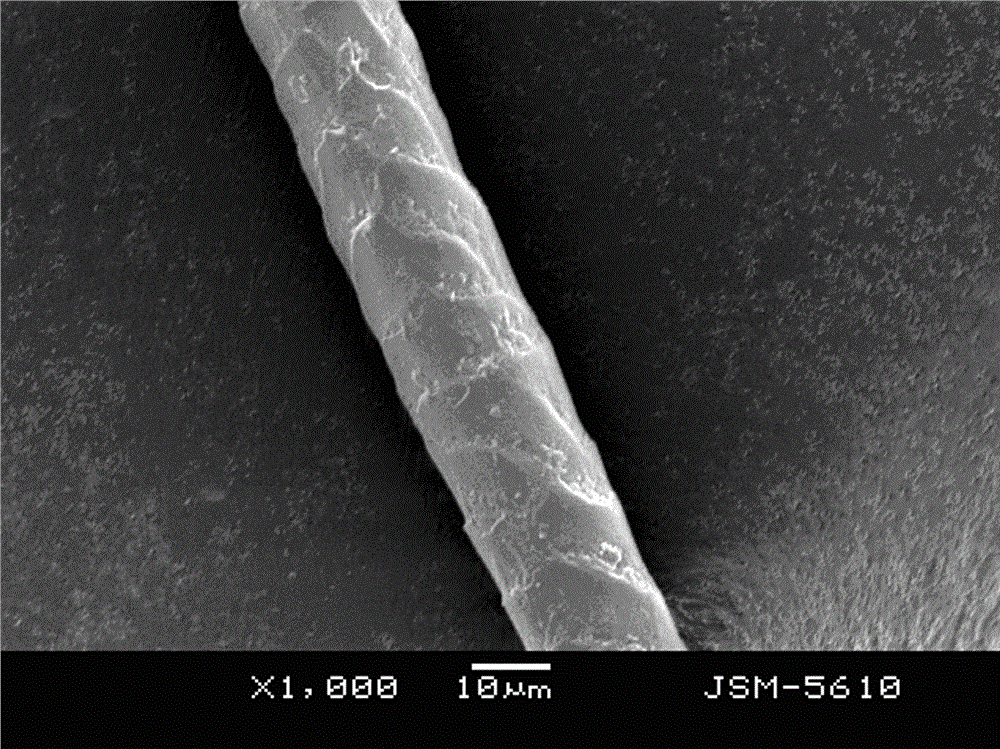

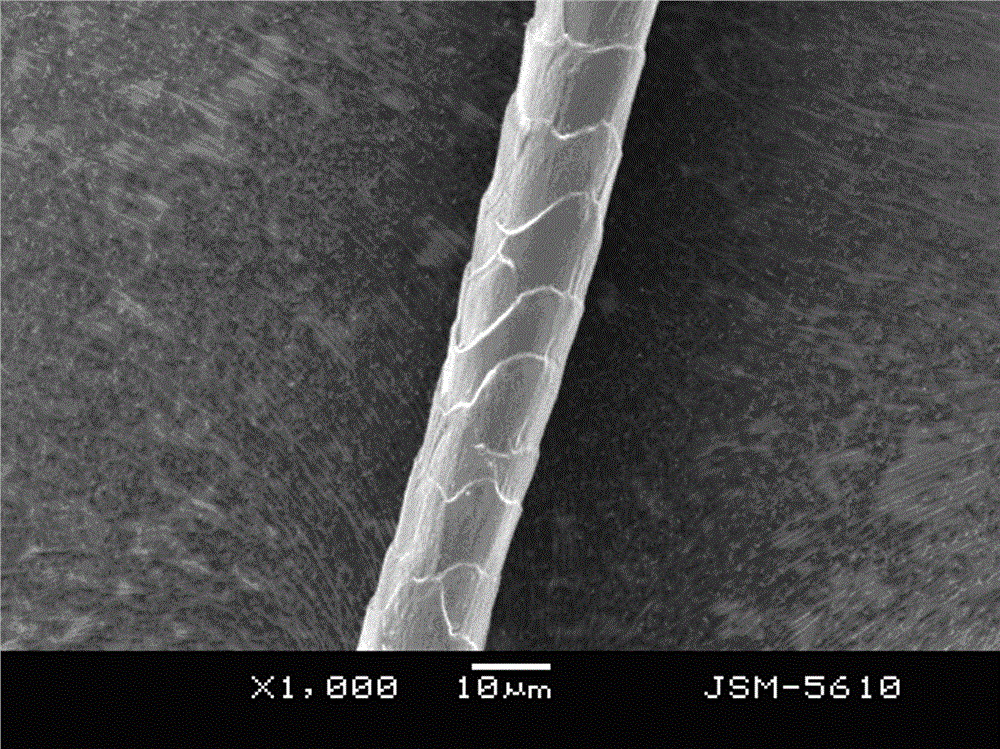

InactiveCN102677450ATo achieve the modified effectAt or close to the modified effectPhysical treatmentBiochemical fibre treatmentFiberScale structure

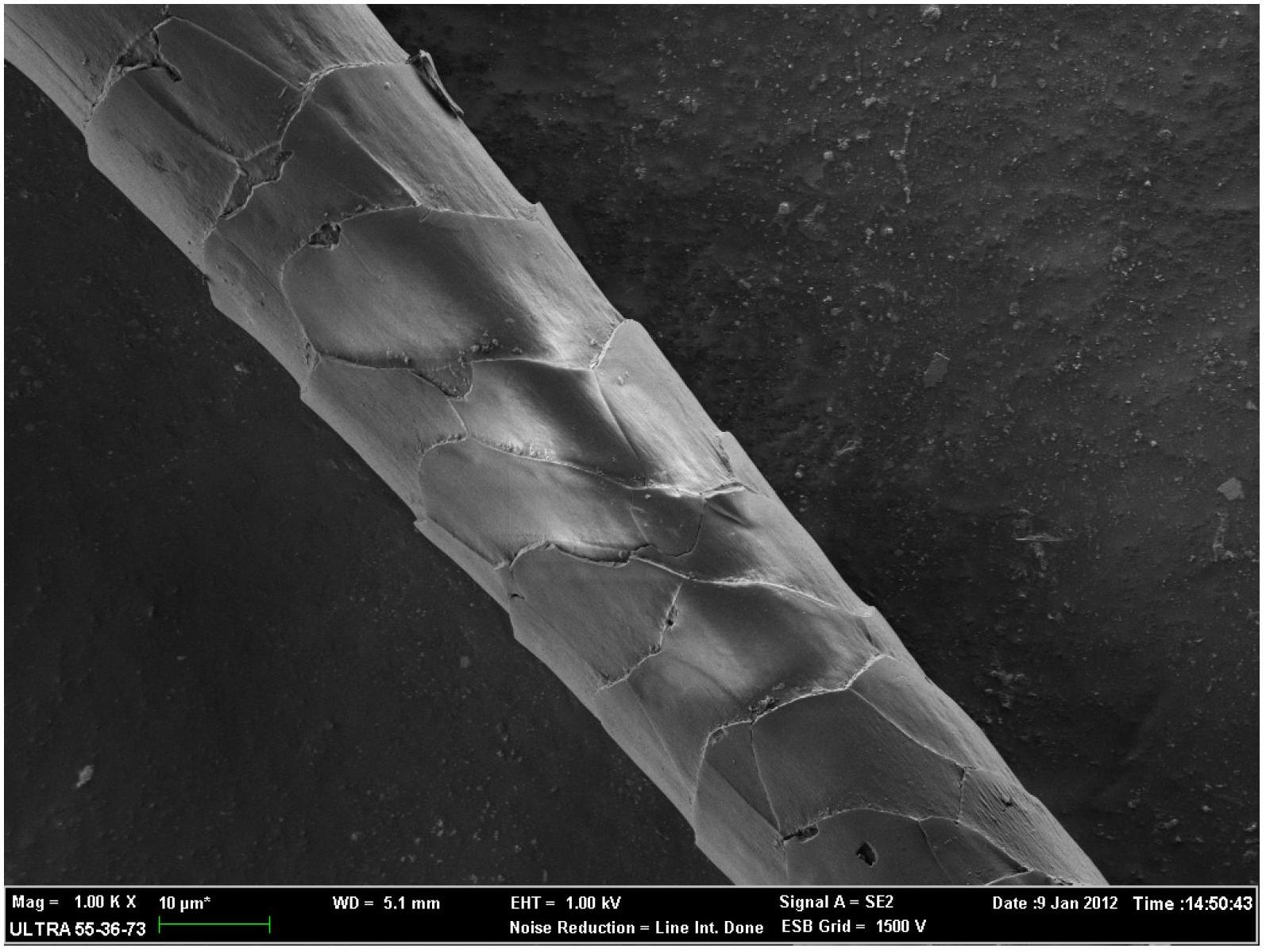

The invention discloses a surface modification method for wool. In the surface modification method for the wool, wool bulk fibers or wool wool tops are used as wool products to be processed and the following steps are sequentially carried out: 1, the wool products to be processed are processed by adopting anatase TiO2 nano particle waterborne dispersing agent; 2, the wool products to be processed, which are obtained in the step 1, are irradiated for 1 to 25 hours by ultraviolet rays with the wavelength range of 250 to 400nm; 3, the wool products to be processed, which are obtained in the step 2, are washed for 20 to 60 minutes by aqueous solution of a surfactant, then are dehydrated and are washed for 2 to 4 times with clear water; and 4, drying the wool products to be processed, which are obtained in the step 3. After the method disclosed by the invention is adopted, a scale structure of the surface of the wool can be partly corroded and damaged or be totally stripped, so that the surface of the wool shows a smooth form.

Owner:ZHEJIANG SCI-TECH UNIV +1

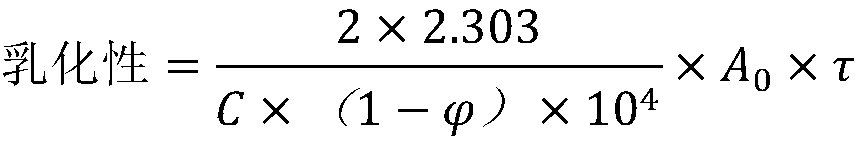

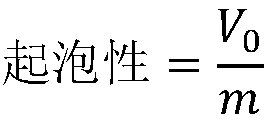

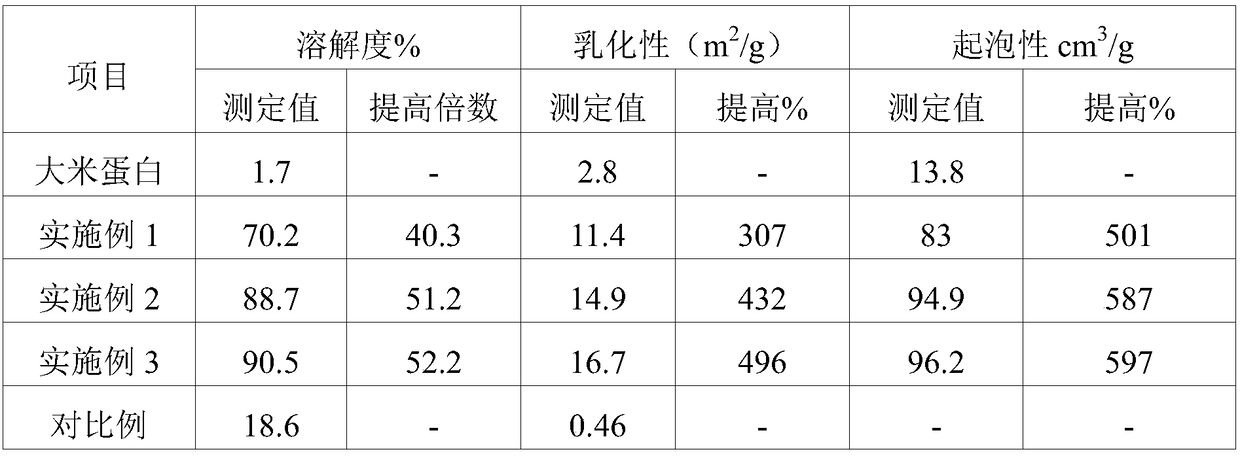

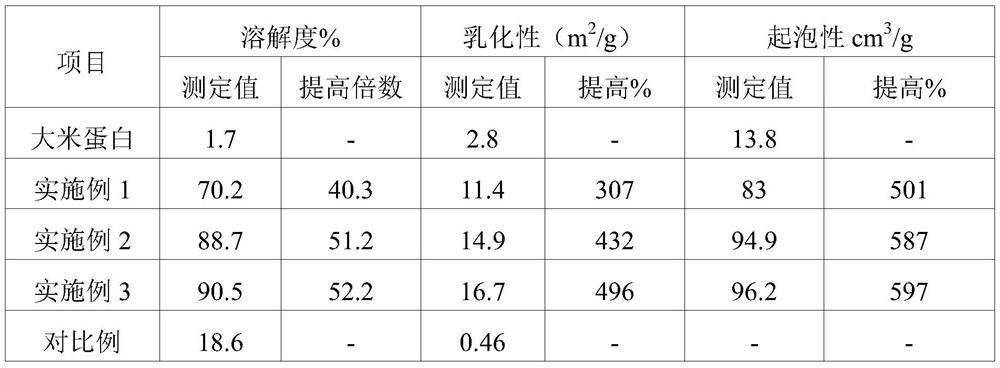

Preparation method for soluble sugar frame rice protein

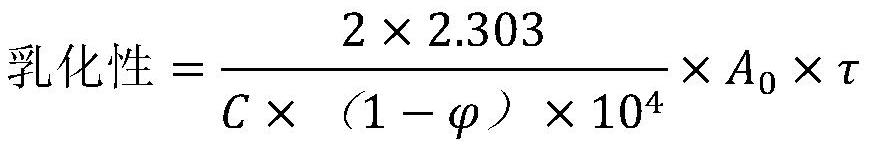

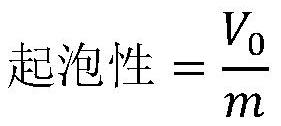

ActiveCN109123065AChange structureTo achieve the modified effectVegetable proteins working-upSolubilityCarboxymethyl cellulose

The invention discloses a preparation method for rice protein with high solubility and a sugar frame structure. Rice protein, carboxymethyl cellulose (sodium), pectin, Arabic gum, sodium alginate, xanthan gum, chitosan or compound polysaccharide of the rice protein are dissolved in an alkaline solution, stirred, neutralized and centrifuged, and after supernate is frozen and dried, soluble sugar frame rice protein is obtained. The sugar frame technology makes the solubility of the rice protein improved by 40 times or above to 70% or above, the emulsibility is improved to 300% or above, the foaming performance is improved by 500% or above, and the application prospect of the rice protein is greatly expanded.

Owner:JIANGNAN UNIV

PVC aeration modified slipper and manufacturing method of the same

The invention relates to a PVC air-blowing modified slipper and making method. The forming raw materials for shoe bottom are formulated with 100 portion of polyvinyl chloride granules, 65 to 75 portion of plasticizers, 0.3 to 0.5 portion of stabilizing agents, 0.3 to 0.4 portion of PVC special scorch retarders for air blowing, 0.35 to 0.45 portion of lubricants, 0.15 to 0.25 portion of PVC special dispersants for air-blowing slipper, 0.1 to 0.2 portion of antioxidants and 0 to 1.5 portion of toners. The forming raw materials are mixed uniformly after going through the working procedure of stirring the materials and are made into the peptized forming raw materials for shoe bottom under the conditions that the temperature ranges from 140 to 200 DEG C and the pressure ranges from 40 to 50MPa; the forming raw materials are injected into a die cavity under the conditions that the pressure ranges from 30 to 40MPa and the temperature ranges from 175 to 185 DEG C; after the die is locked, the air is blown into the peptized forming raw materials for shoe bottom and the pressure of the air ranges from 0.8 to 1.2MPa and the blowing time ranges from 2.0 to 3.0s; after the forming and demolding are carried out, the PVC air-blowing modified slipper is obtained. The invention has the advantages of being convenient for recycling the materials, environmental protection, slippage prevention, coldness resistance, abrasion resistance, lightness and convenience. The shoe bottom has good pliability and the shoe is uneasy to be aged.

Owner:黄世海

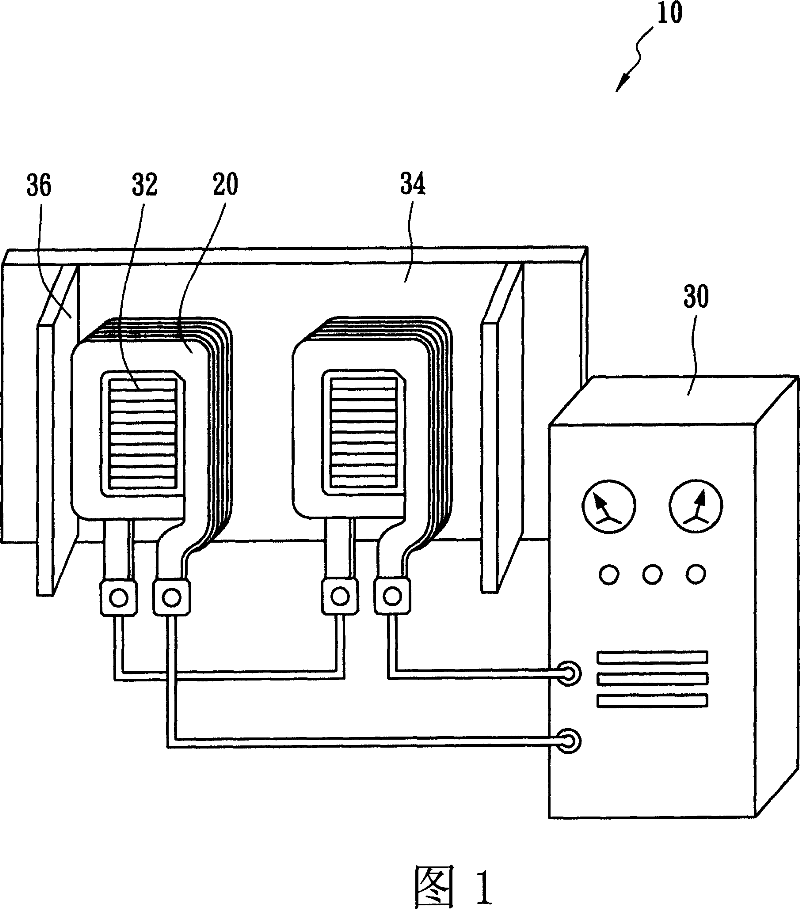

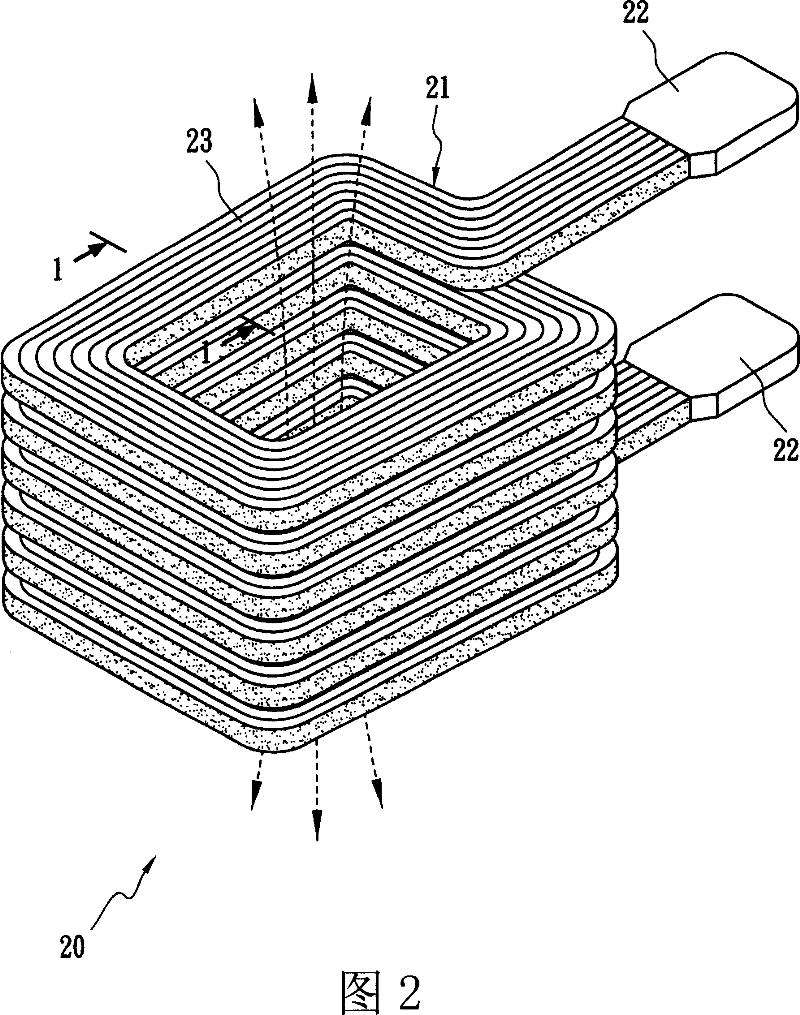

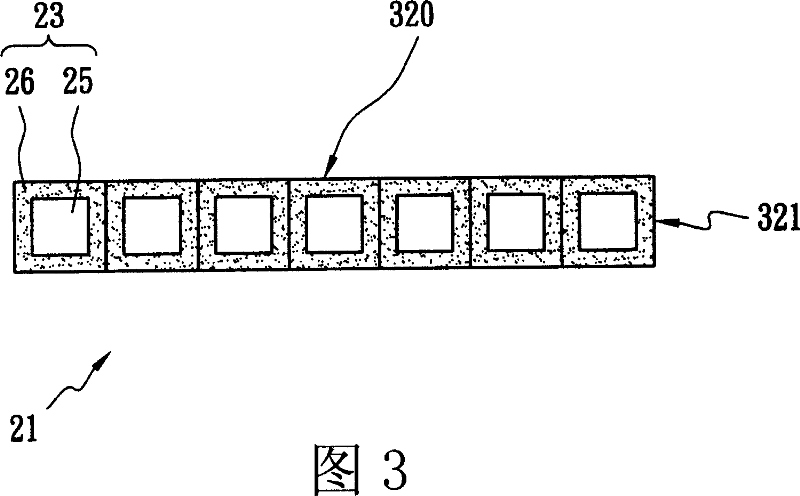

Device and method for substance modification

InactiveCN101036497ATo achieve the modified effectRefining by electric/magnetic meansFood preparationMagnetic coreElectricity

The invention provides a matter modifying device, comprising at least two electromagnetic coils and a power supply for the electromagnetic coils. The two electromagnetic coils are provided opposite polarity (viz N-pole and S-pole) after being switched into conduction, and each coil is formed by spiral wrapping of plane wire cluster with a plurality of leads, wherein the plurality of leads are insulated each other. Each electromagnetic coil enwinds a magnetic core, wherein the magnetic core is a combination with a plurality of magnetic-conductive iron sheets, which facilitates release of oscillatory wave, conduction of magnetic force line, and configuration and preparation of said electromagnetic coils. An object is placed in front of the magnetic force line of magnetic field of said electromagnetic coils, and the electromagnetic coils are switched into conduction for forming electromagnetic effect. By interaction like electricity-generated-from-magnetism, magnetism-generated-from-electricity, and oscillation from interaction between magnetic fields, etc, a micrometerization (up to molecular nanometerization period) process of molecular agglomeration and dispersion can be carried out, thereby modifying matter.

Owner:郭淑芬

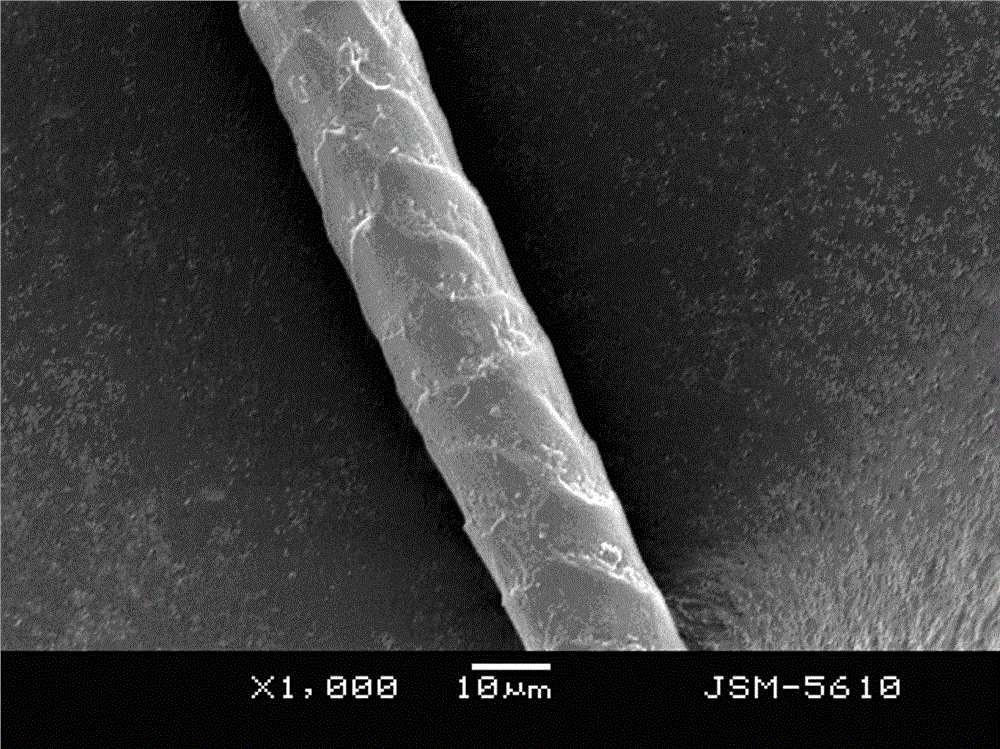

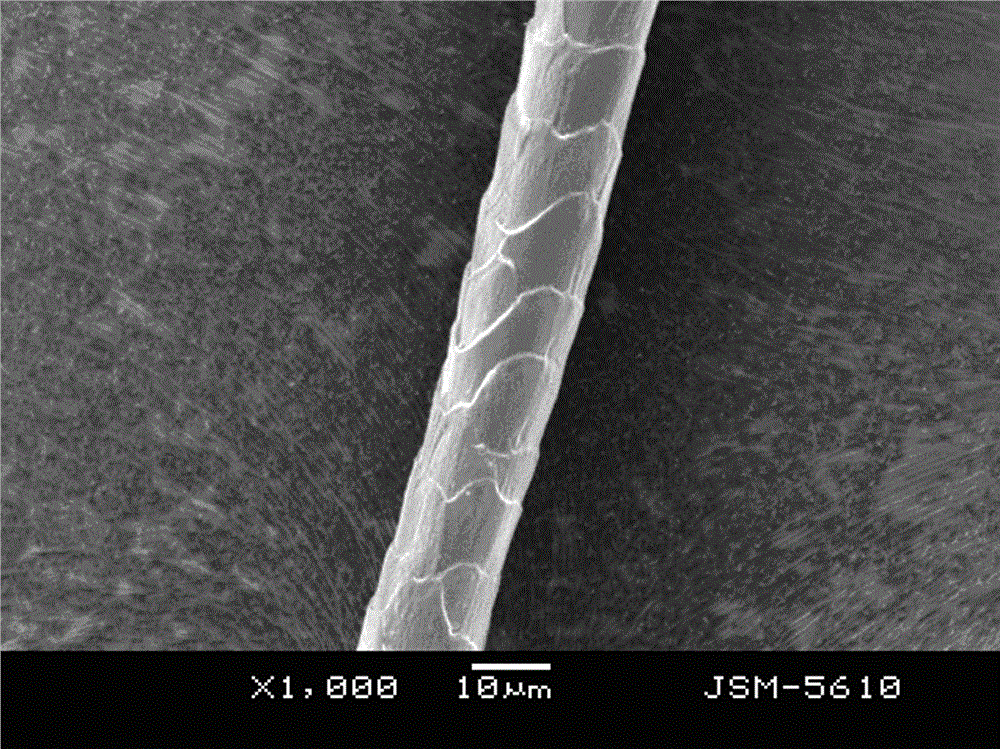

Wool surface catalytic oxidation and modification method

ActiveCN103820991ATo achieve the modified effectBiochemical fibre treatmentAnimal fibresNanoparticleCatalytic oxidation

The invention discloses a wool surface catalytic oxidation and modification method and aims to provide a method for enabling a squama structure part on the surface of wool to be damaged by corrosion or totally stripped and enabling the surface of the wool to be in a smooth form. The wool surface catalytic oxidation and modification method comprises the steps: adding iron-oxide nanoparticles in a dispersant solution to obtain an iron-oxide nanoparticle aqueous dispersion; treating a wool product to be treated by the iron-oxide nanoparticle aqueous dispersion, and enabling the iron-oxide nanoparticles to be uniformly adhered to the surface of the wool product to be treated; treating the obtained wool product to be treated by a solution prepared by H2O2, enabling the adhesion part or the periphery of the iron-oxide nanoparticles to generate location catalytic oxidation, corroding a squama structure on the surface of the wool, and enabling the surface of the wool to be modified; carrying out washing and dehydration by using an aqueous surfactant solution, washing by clean water, and drying. With the adoption of the wool surface catalytic oxidation and modification method, most of the squama structure on the surface of the wool is damaged by corrosion, and the method has the advantages of no AOX (Adsorbable organic chloride) emission and residue by adopting a chloride-free treating method.

Owner:山东神州毛纺织有限公司

High-performance heat-conducting silicone grease and preparation method thereof

The invention belongs to the technical field of thermal interface organic heat conduction materials. The invention relates to the technical field of silicone grease, in particular to high-performanceheat-conducting silicone grease and a preparation method thereof, the heat-conducting silicone grease is specifically composed of 8%-20% of matrix heat-conducting oil, 75%-91% of heat-conducting filler and 0.05%-5% of a modifier, wherein the heat-conducting filler is mainly graphene and aluminum oxide. According to the preparation method, modification of graphene is realized by adding graphene into an ethanol solution of a modifier and carrying out heating and stirring; the modification of aluminum oxide is completed by directly adding a modifier into matrix heat-conducting oil, uniformly heating and stirring the mixture for uniform dispersion, wherein the oleophylic group of the modifier is combined with the matrix oil; then adding the modifier into the matrix oil, adding the alumina powder, and heating and stirring the mixture to connect the hydrophilic group of the modifier to the surface of the powder, thereby implementing favorable dispersion of the powder particles in the matrixoil, enhancing the combination between the matrix oil and the particles, reducing the defects of the bonding interface and lowering the interface thermal resistance between the heat-conducting fillerparticles and the matrix.

Owner:大连理工大学重大装备设计与制造郑州研究院 +1

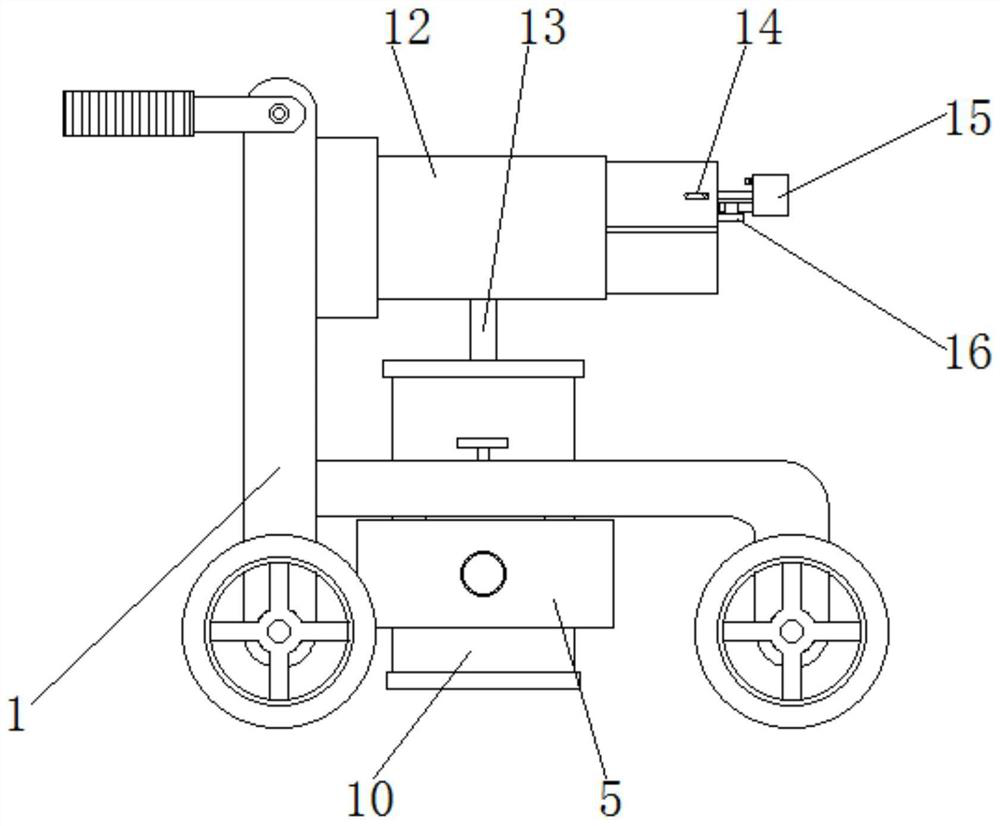

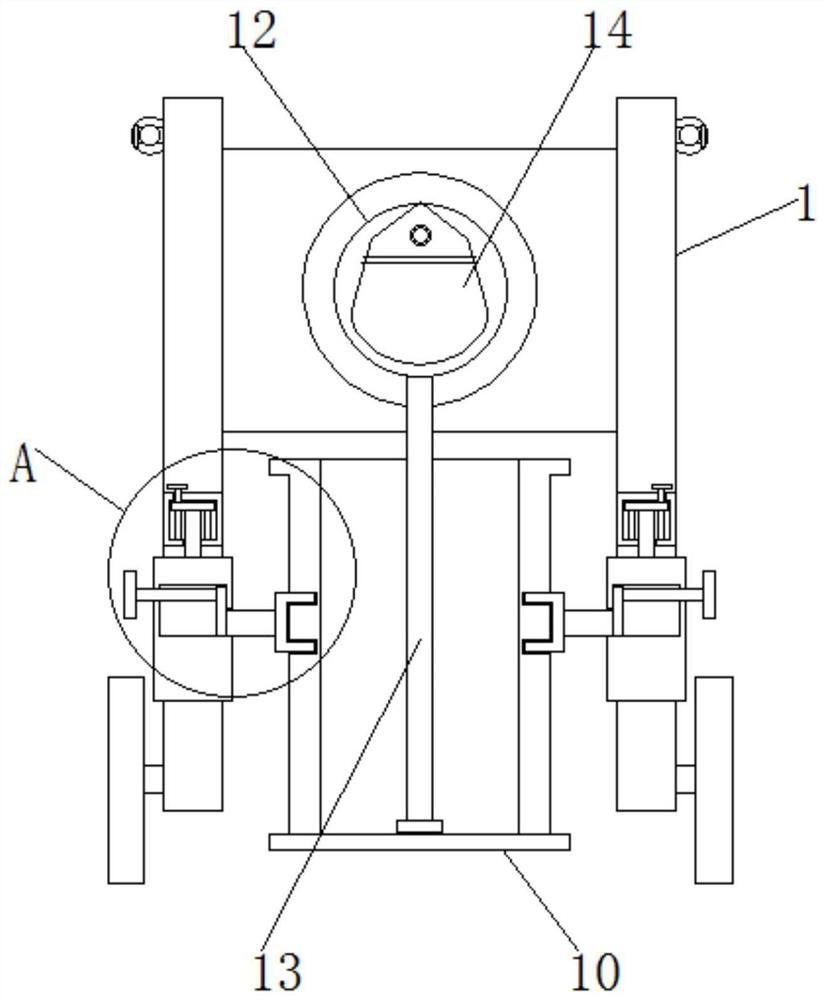

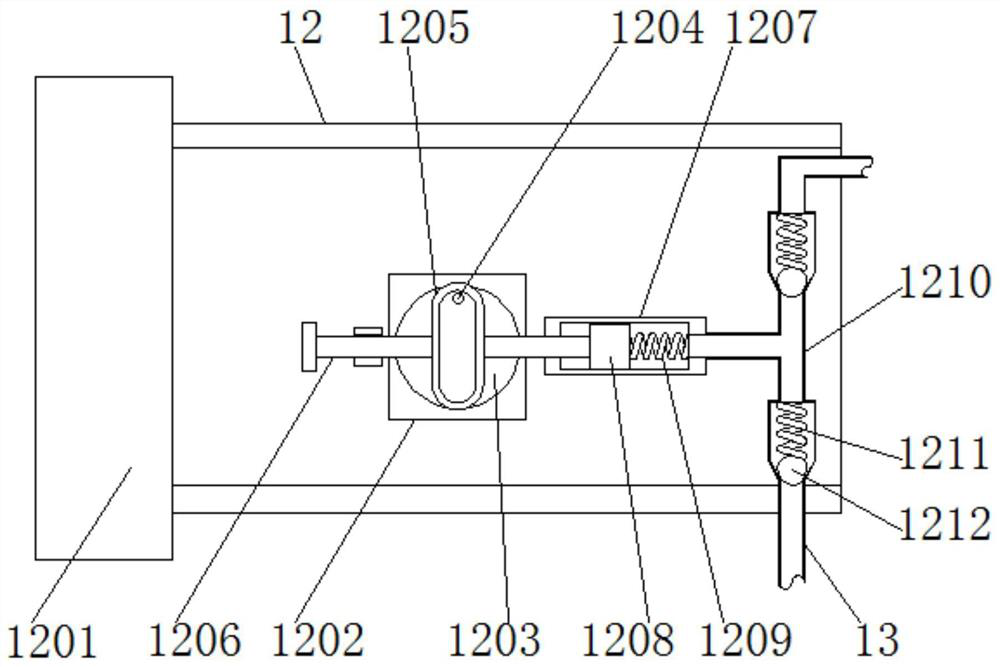

Spraying instrument special for waterproof heat-preservation outer wall coating

InactiveCN112854683AEasy to installEasy accessBuilding constructionsCoatingsSpray nozzleStructural engineering

The invention discloses a spraying instrument special for a waterproof heat-preservation outer wall coating. The spraying instrument comprises a cart and a taking and placing device, wherein one side, close to a first threaded rod, of the cart is connected with a first guide rod, and the taking and placing device is fixed on one side of a binding device. According to the spraying instrument special for the waterproof heat preservation outer wall coating, a spraying device is arranged, the coating in a three-way pipe enters a hose through a conveying pipe, then enters a spraying head at one end through the hose and is sprayed out through a mist spraying opening in one side of the spraying head, a third threaded rod is rotated, the third threaded rod drives the spraying head to move in the direction of a second guide rod, the spraying head moves to extrude sealing gaskets on the two sides, pressure borne by the sealing gaskets is transmitted to a stopping block, the stopping block is stressed to extrude a third spring to enter a groove, the number of spraying nozzles blocked by the sealing gaskets is smaller and smaller, the number of spraying nozzles capable of being sprayed is larger and larger, the spraying area is increased due to the increase of the number of the spraying nozzles, and the spraying area is convenient to control.

Owner:于文琦

Waterproof thermal-insulation exterior wall coating for buildings and preparation method thereof

ActiveCN112251098AOvercoming the defects of being hot, sticky and brittleRetain alkali resistanceCoatingsFiberActivated carbon

The invention discloses a waterproof thermal insulation exterior wall coating for buildings and a preparation method thereof. The waterproof thermal insulation exterior wall coating is prepared from afluorosilicone modified acrylic emulsion, graphene acrylic acid composite emulsion, silica sol, activated carbon fiber powder, fluorosilane, titanium dioxide and auxiliaries, and the auxiliaries comprise a dispersing agent, a wetting agent, a thickening agent, a defoaming agent, a coalescing agent and an anti-freezing agent. The preparation method comprises the following steps: uniformly mixing the silica sol, activated carbon fiber powder and titanium dioxide, adding a fluorosilicone modified acrylic emulsion and a graphene-acrylic composite emulsion, uniformly mixing, adding the assistant,uniformly mixing, and finally mixing with fluorosilane. The waterproof thermal insulation exterior wall coating for the building has excellent waterproof and thermal insulation properties, is self-cleaning and washable, and is suitable for various external environments.

Owner:王洪磊

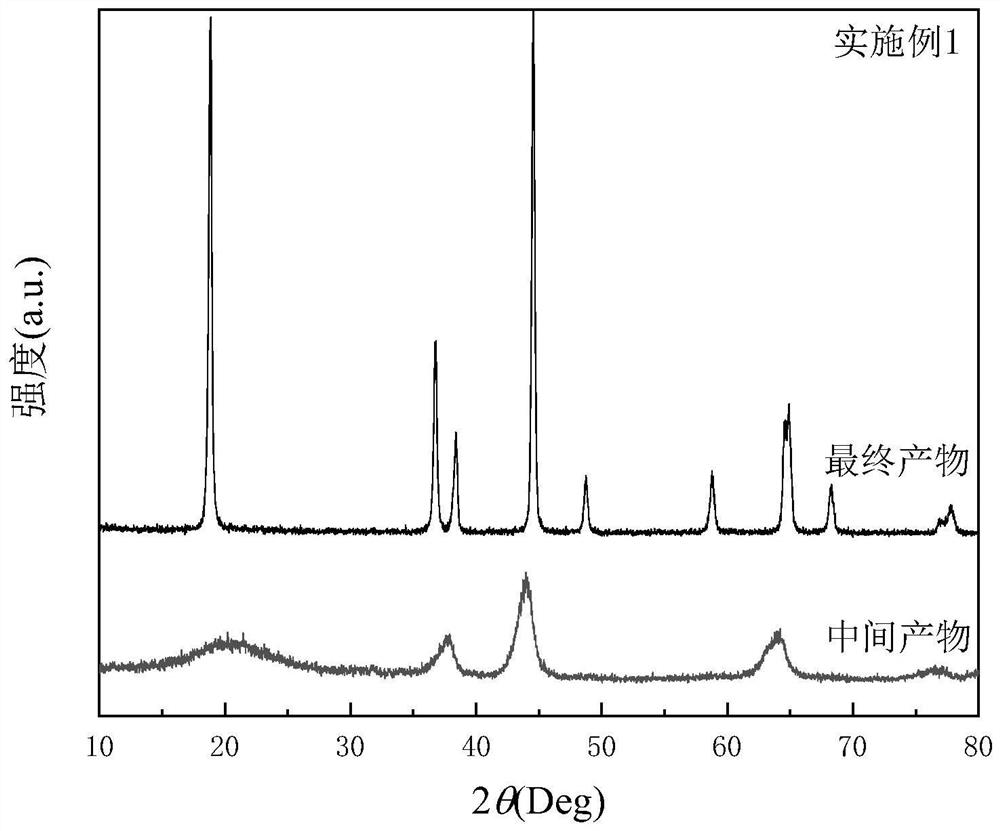

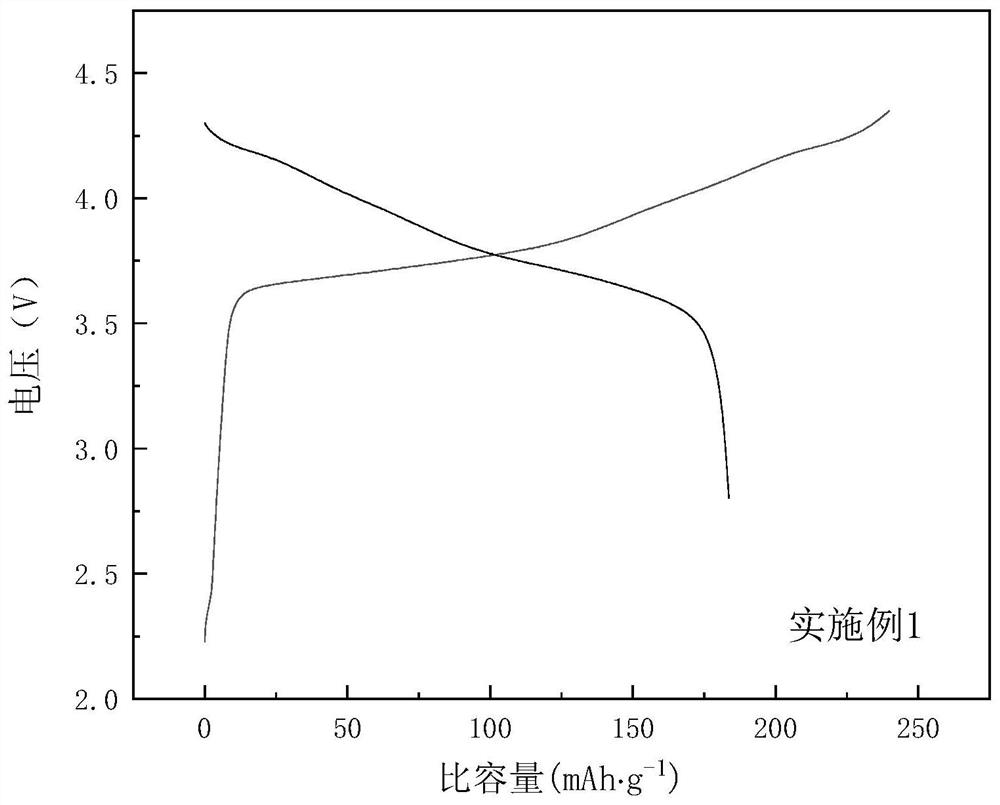

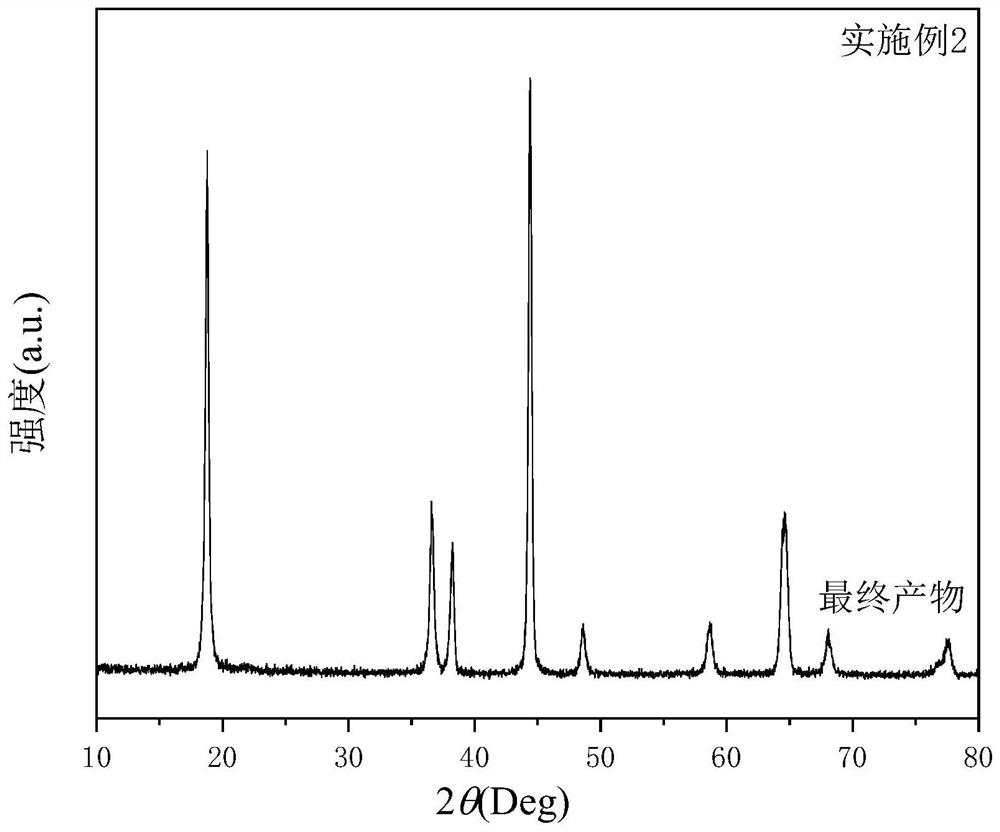

Preparation method of nickel cobalt lithium manganate positive electrode material

ActiveCN113130888ANo emissionsTo achieve the modified effectSecondary cellsPositive electrodesAir atmosphereManganate

The invention discloses a preparation method of a nickel cobalt lithium manganate positive electrode material. The preparation method comprises the following steps of dissolving soluble salts of lithium, nickel, cobalt and manganese in deionized water to form a precursor solution, sending the precursor solution to an ultrasonic spraying device to be atomized into liquid drops, forming aerosol with carrier gas, sending the aerosol to a high-temperature pyrolysis device through the carrier gas to be pre-calcined, wherein the pre-calcined product is relatively fine in grain, the 003 crystal face development is not complete, the oxidation reaction is not sufficient, and transferring the pre-calcined product to heat treatment equipment to be subjected to high-temperature heat treatment for a plurality of hours in an oxygen or air atmosphere, so that the final product lithium nickel cobalt manganate with complete crystal lattice development can be obtained. The preparation method has the advantages of short process flow, low time consumption, pure product, convenience in realization of automatic control, no waste liquid discharge and the like, and belongs to a green and environment-friendly production technology. Through adopting the preparation method, a ternary nickel-cobalt-manganese composite metal oxide or a single transition metal oxide can be obtained, and a doped modified nickel-cobalt lithium manganate positive electrode material can further be obtained.

Owner:BEIFANG UNIV OF NATITIES +1

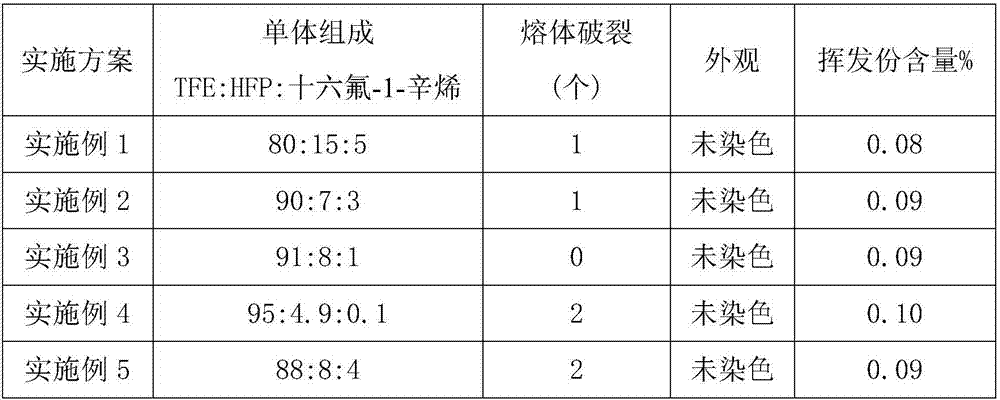

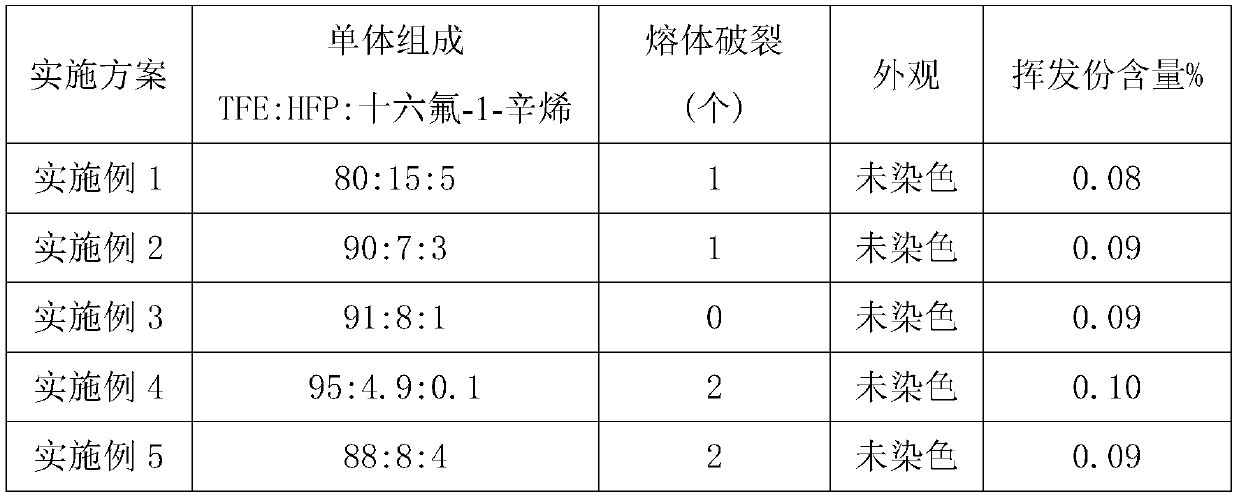

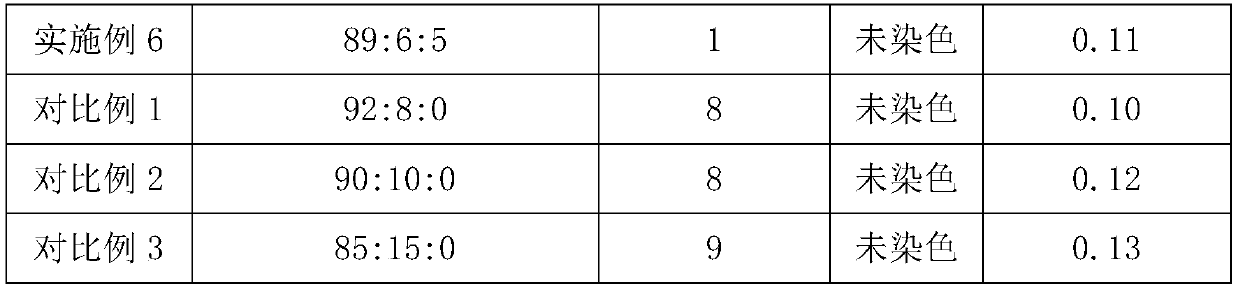

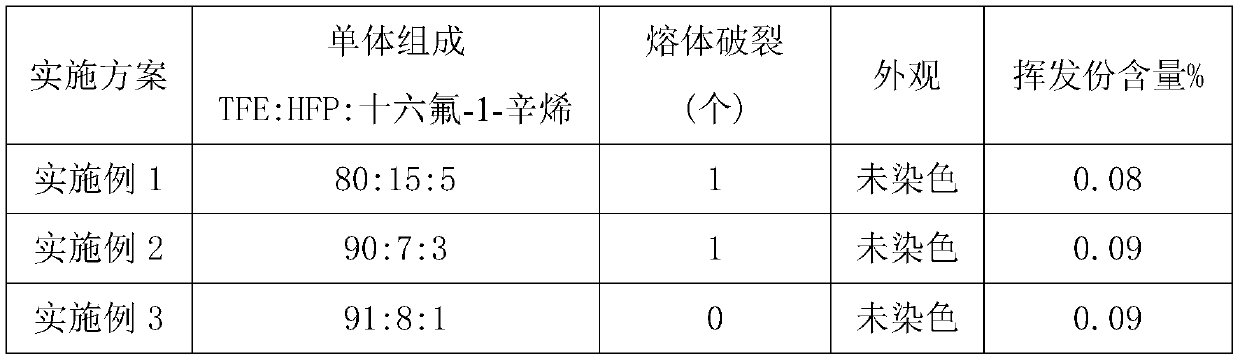

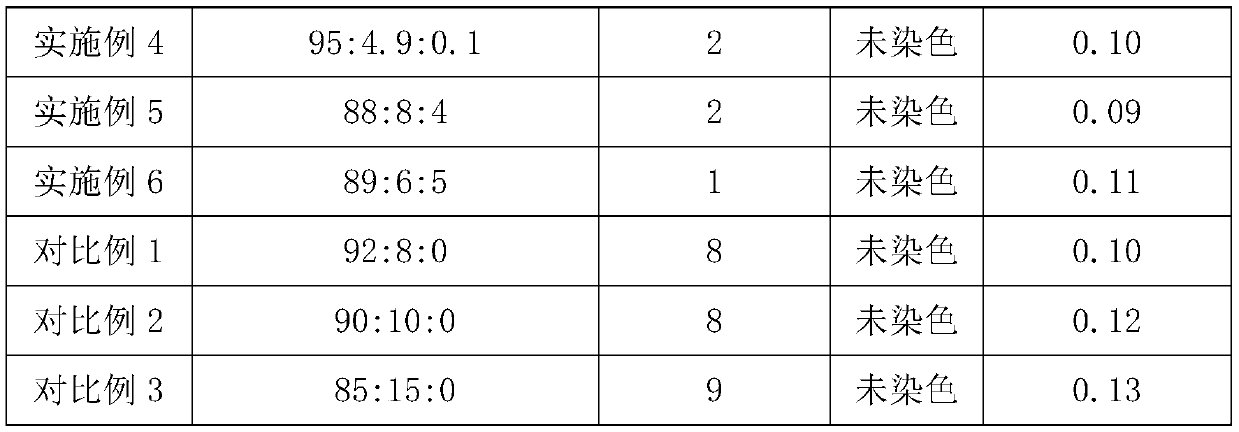

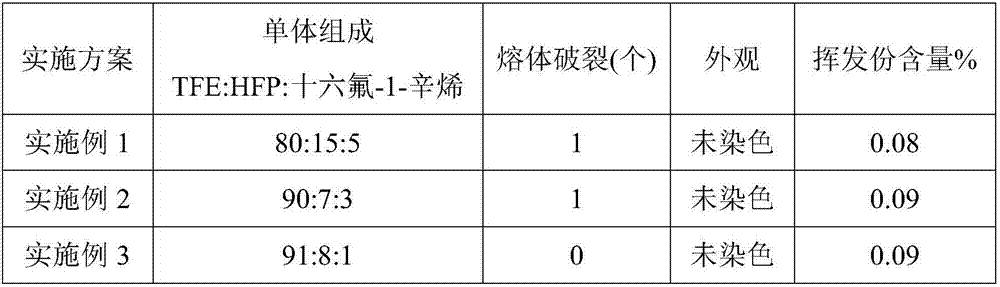

Hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and solution polymerization preparation method thereof

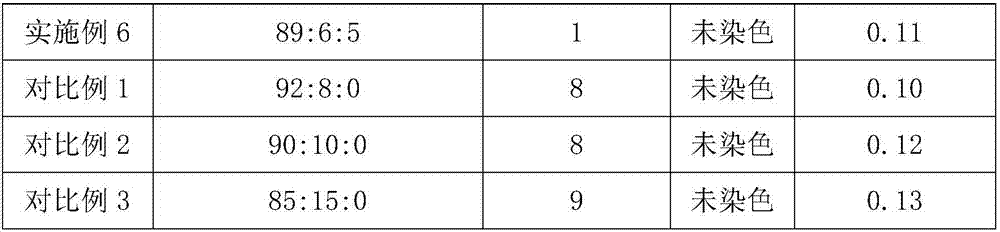

The invention discloses a hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and a solution polymerization preparation method thereof. According to the solution polymerization preparation method, tetrafluoroethylene, hexafluoropropylene and hexadecafluoro-1-octene serve as copolymerizable monomers, wherein a molar fraction of the tetrafluoroethylene to hexafluoropropylene to hexadecafluoro-1-octene is (80-95):(4.9-15):(0.1-5). The preparation process comprises the following steps: adding a fluorine-containing solvent and copolymerizable monomers into a reactor at a certain temperature, raising the temperature to 20-60 DEG C, adding a perfluoro initiator to initiate a polymerization reaction under the pressure of 1.1-1.5MPa, supplementing the copolymerizable monomers in the reaction process, and finally preparing the modified polyperfluoro ethylene-propylene. The modified monomers are taken as polyperfluoro monomers, so that the prepared modified polyperfluoro ethylene-propylene resin is excellent in heat resistance, causes no aggregate dyeing phenomenon, can serve as a high-speed extrusion grade product and can be stably coated on a cable surface at a high speed of 300-500m / min.

Owner:JUHUA GROUP TECH CENT

Preparation method of waterproof thermal-insulation exterior wall coating for building

InactiveCN114031996AOvercoming the defects of being hot, sticky and brittleRetain alkali resistanceCoatingsFiberActivated carbon

The invention discloses a preparation method of a waterproof thermal-insulation exterior wall coating for buildings, and the coating comprises the following components: a fluorosilicone modified acrylic emulsion, a graphene-acrylic acid composite emulsion, silica sol, activated carbon fiber powder, fluorosilane, titanium dioxide and an auxiliary agent, the auxiliary agent comprises a dispersing agent, a wetting agent, a thickening agent, a defoaming agent, a coalescing agent and an anti-freezing agent. The preparation method comprises the following steps: uniformly mixing silica sol, activated carbon fiber powder and titanium dioxide, adding fluorosilicone modified acrylic emulsion and graphene-acrylic composite emulsion, uniformly mixing, adding the auxiliary agent, uniformly mixing, and finally mixing fluorosilane. The waterproof thermal-insulating exterior wall coating for the buildings has excellent waterproof and heat-insulating properties, is self-cleaning and washable, and is suitable for various external environments.

Owner:王洪磊

Surface modification method for wool

InactiveCN102677450BTo achieve the modified effectAt or close to the modified effectPhysical treatmentBiochemical fibre treatmentFiberScale structure

The invention discloses a surface modification method for wool. In the surface modification method for the wool, wool bulk fibers or wool wool tops are used as wool products to be processed and the following steps are sequentially carried out: 1, the wool products to be processed are processed by adopting anatase TiO2 nano particle waterborne dispersing agent; 2, the wool products to be processed, which are obtained in the step 1, are irradiated for 1 to 25 hours by ultraviolet rays with the wavelength range of 250 to 400nm; 3, the wool products to be processed, which are obtained in the step 2, are washed for 20 to 60 minutes by aqueous solution of a surfactant, then are dehydrated and are washed for 2 to 4 times with clear water; and 4, drying the wool products to be processed, which are obtained in the step 3. After the method disclosed by the invention is adopted, a scale structure of the surface of the wool can be partly corroded and damaged or be totally stripped, so that the surface of the wool shows a smooth form.

Owner:ZHEJIANG SCI-TECH UNIV +1

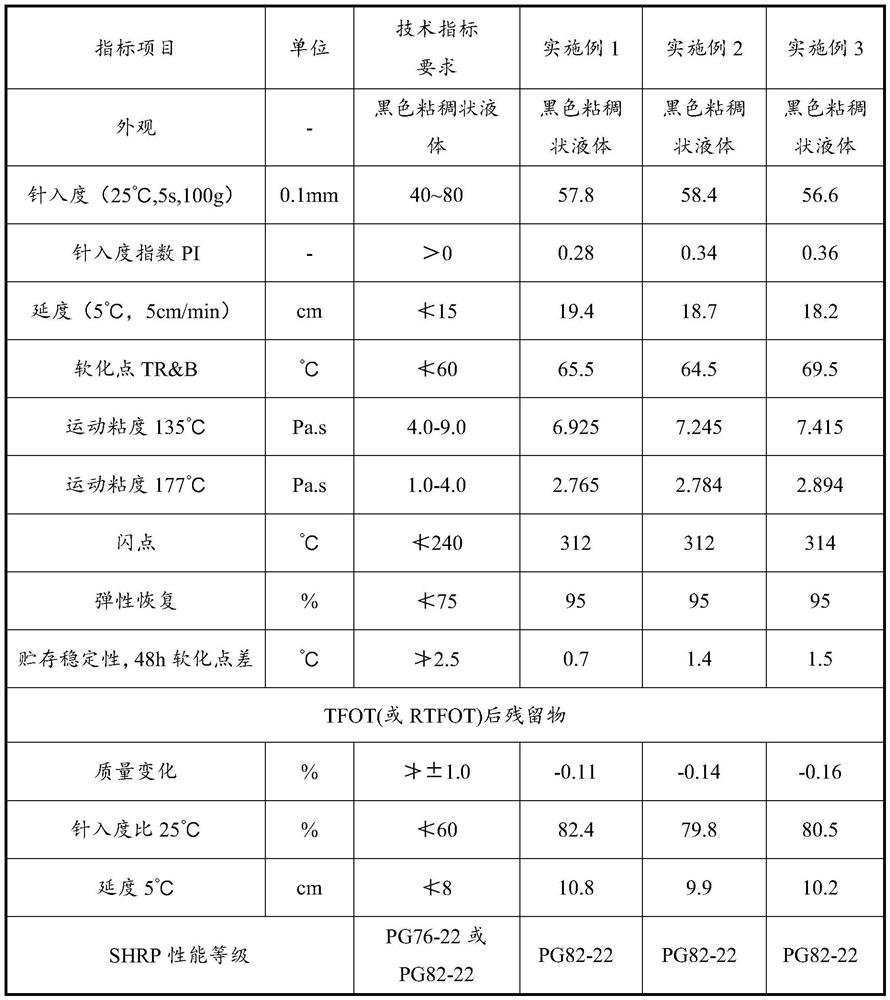

Environment-friendly rubber asphalt with stable storage performance and preparation method of rubber asphalt

InactiveCN112724694AStable production and storage performance and environmental protectionImprove performanceBuilding insulationsAlkaneChemical reaction

The invention discloses environment-friendly rubber asphalt with a stable storage performance and a preparation method of the rubber asphalt. The rubber asphalt comprises the following components in parts by weight: 30-45 parts of rubber powder, 55-70 parts of road petroleum asphalt, 0-0.2 part of a modifier and 0.02-0.2 part of a stabilizer. The preparation process comprises the following steps that the rubber powder is mixed with the road petroleum asphalt to form a blending system; then the modifier is added, particles or filaments are distributed in an asphalt matrix along with the modifier, a loose net structure is formed and exists in the asphalt matrix, and a modification effect is achieved; finally, the stabilizer is added to be subjected to chemical reaction with alkane, olefin, aromatic hydrocarbon and polar and non-polar compounds in the asphalt to generate new chemical bond combination, so that the prepared asphalt product is more stable in property, and the storage stability of the asphalt product is improved. The preparation method disclosed by the invention is simple and convenient to operate, low in production cost and environment-friendly in production process, and the produced asphalt is stable in storage performance and not easy to separate and has high practical and economic values.

Owner:江苏亿虎沥青材料有限公司

A method for catalytic oxidation modification of wool surface

ActiveCN103820991BTo achieve the modified effectBiochemical fibre treatmentAnimal fibresCatalytic oxidationSurface-active agents

The invention discloses a wool surface catalytic oxidation and modification method and aims to provide a method for enabling a squama structure part on the surface of wool to be damaged by corrosion or totally stripped and enabling the surface of the wool to be in a smooth form. The wool surface catalytic oxidation and modification method comprises the steps: adding iron-oxide nanoparticles in a dispersant solution to obtain an iron-oxide nanoparticle aqueous dispersion; treating a wool product to be treated by the iron-oxide nanoparticle aqueous dispersion, and enabling the iron-oxide nanoparticles to be uniformly adhered to the surface of the wool product to be treated; treating the obtained wool product to be treated by a solution prepared by H2O2, enabling the adhesion part or the periphery of the iron-oxide nanoparticles to generate location catalytic oxidation, corroding a squama structure on the surface of the wool, and enabling the surface of the wool to be modified; carrying out washing and dehydration by using an aqueous surfactant solution, washing by clean water, and drying. With the adoption of the wool surface catalytic oxidation and modification method, most of the squama structure on the surface of the wool is damaged by corrosion, and the method has the advantages of no AOX (Adsorbable organic chloride) emission and residue by adopting a chloride-free treating method.

Owner:山东神州毛纺织有限公司

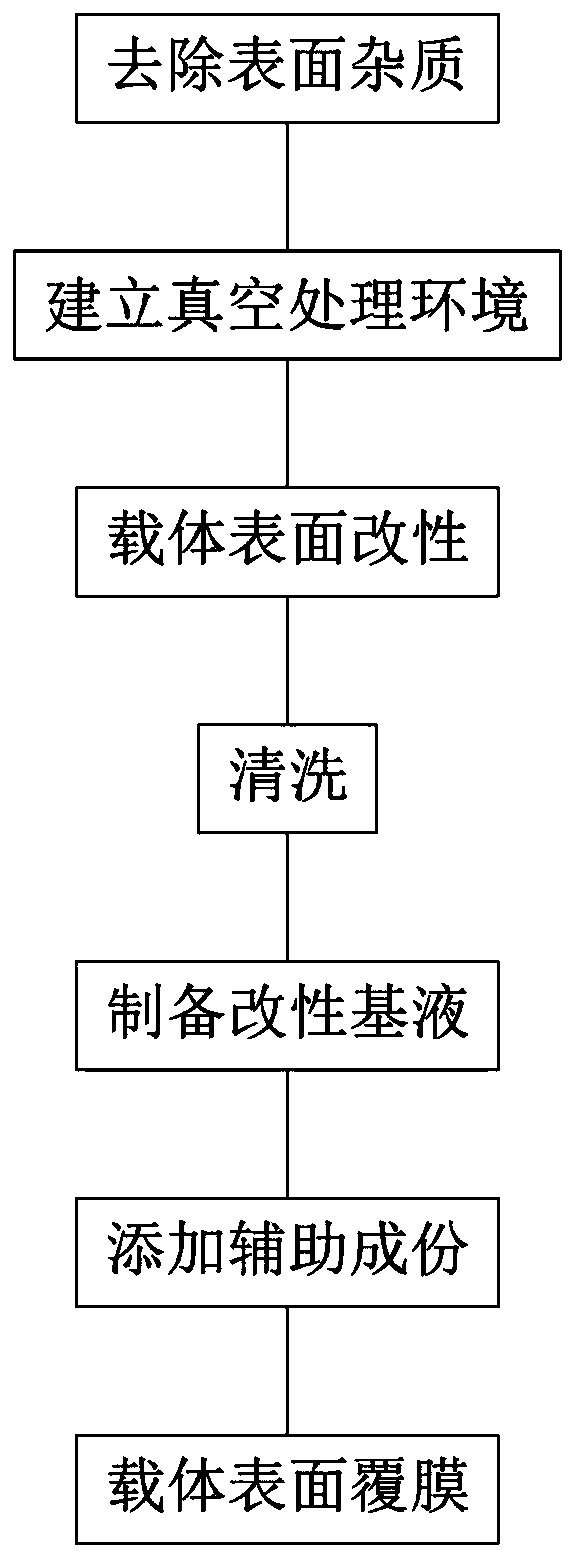

Vector processing technology

InactiveCN110527135AImprove hydrophilicityTo achieve the modified effectOther foreign material introduction processesBiological water/sewage treatmentAfter treatmentSurface modification

The invention discloses a vector processing technology and relates to the technical field of microbe vectors. The vector processing technology is used for solving the problem that vector hydrophilicity is relatively poor. The vector processing technology is characterized by comprising the following steps: establishing a vacuum treatment environment; carrying out vector surface modification; preparing modification base fluid; and carrying out vector surface coating. A vector reacts with oxygen gas through action of plasma, and a hydrophilic oxo group is formed on the surface of the vector, so that the hydrophilicity of the surface of the vector can be remarkably improved, the advantage that the hydrophilicity of the surface of the treated vector is relatively good is achieved, and the effect of modifying the surface of the vector is achieved. The surface hydrophilicity of the vector is directly improved through PVA attached to the surface of the vector. After treatment through a vectorsurface modification step, the vector can have a higher degree of combination with the modification base fluid, the modification base fluid is prevented from accidentally spalling from the surface ofthe vector, and thus, microbes connected to the modification base fluid can more stably grow on the surface of the vector.

Owner:广东中良环保工程有限公司

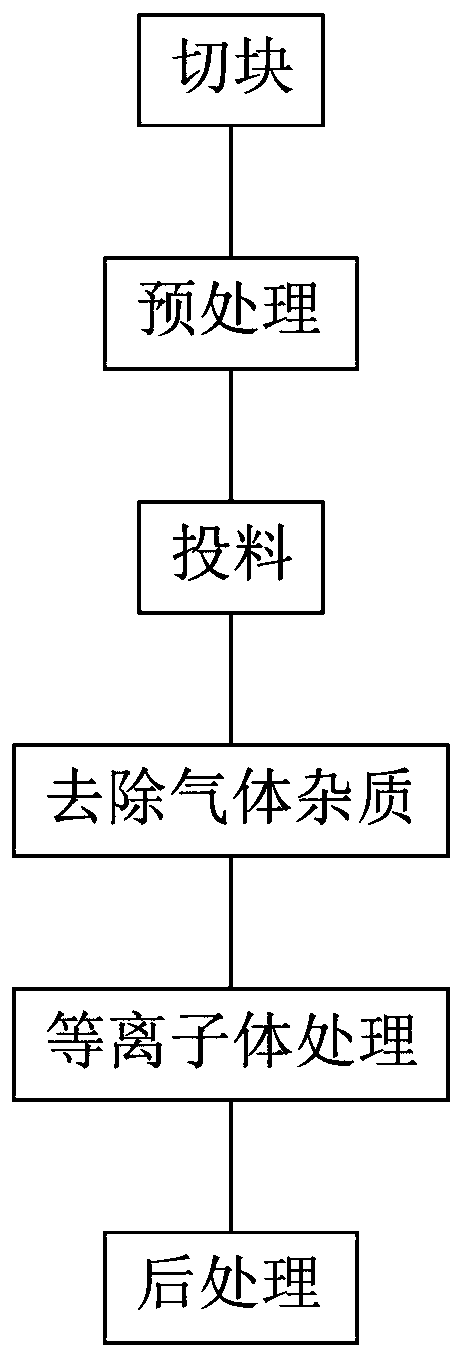

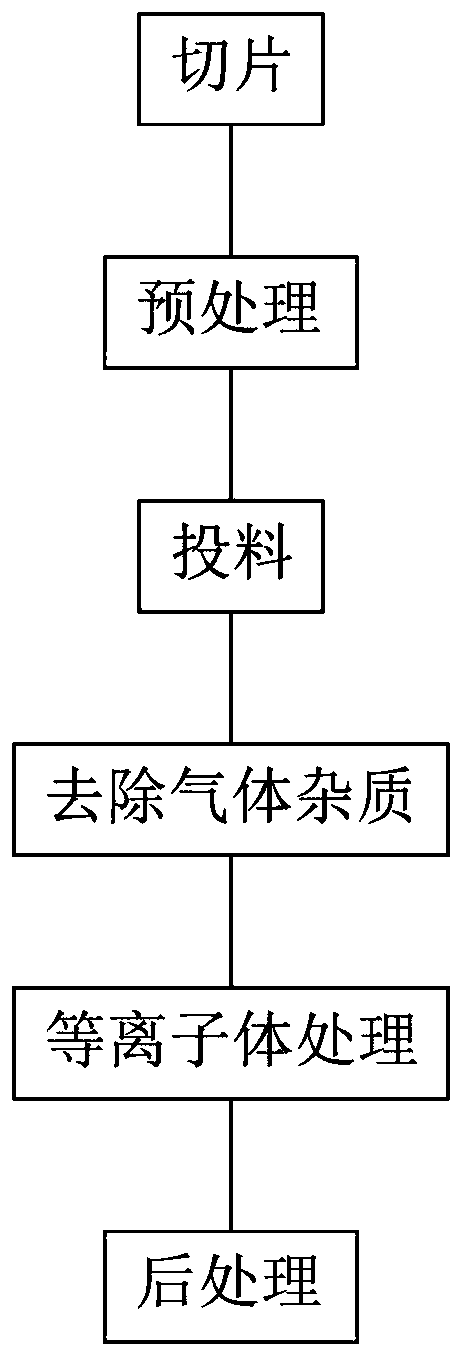

Surface treatment method of foaming material

InactiveCN110408073ATo achieve the modified effectImprove hydrophilicityCoatingsAlternating currentOxygen

The invention discloses a surface treatment method of a foaming material and relates to the technical field of surface treatment. An existing foaming material has the defect of poor hydrophilicity. The surface treatment method is technically characterized by comprising the steps: material feeding, wherein the foaming material is placedin a closed processing bin; plasma treatment, wherein the two sides of the foaming material are separately provided with an electrode, argon and oxygen are injected into the processing bin, alternating current with the working frequency of 10 MHz is introduced into the two electrodes, the alternating current electric power is greater than 150 W but does not exceed 5000 W, the argon and the oxygen obtain energy in an electric field generated by the two electrodes and form plasma, and the plasma moves with the change of the electric field and collides with the foaming material, so that chemical bonds of polymers on the surface of the foaming material breakand free radicals are formed; the free radicals react with oxygen to form hydrophilic oxygen-containing groups. The surface is uneven, the surface area is increased, the activity of the surface molecular groups can be enhanced, and the advantage of better surface hydrophilicity is achieved, so that the foaming material is convenient to use.

Owner:广东中良环保工程有限公司

Flux capable of reducing oxidability of steel ladle top dross

InactiveCN103436658ATo achieve the modified effectMeet the test requirements for nitrogen increaseProcess efficiency improvementMolten steelDross

The invention relates to an auxiliary material for steel smelting, in particular to a flux capable of reducing oxidability of steel ladle top dross. The invention aims at providing the flux capable of reducing the oxidability of the steel ladle top dross. The flux mainly reduces sigma (FeO+MnO)% in the steel ladle top dross, raises a degree of purity of molten steel, and simultaneously solves the technical problem that the common modifier cannot achieve nitrogen adding. The flux adopts the technical scheme that the flux capable of reducing the oxidability of the steel ladle top dross comprises the following chemical constituents by weight percentage: 57-70% of CaO, 15-28% of Al2O3, 3.5-7% of Al, 6-10% of CaC2, 1.5-5% of MgO, less than 3% of SiO2, less than or equal to 0.01% of C, and less than or equal to 0.3% of water. Therefore, an appropriate amount of the modifier is added during steel tapping of a converter, average sigma (FeO+MnO)% is 1.4% when the steel exits an argon station, and a modification effect is achieved. In addition, 2ppm nitrogen is added during a test, so that the nitrogen adding test requirement is met.

Owner:NANJING MEISHAN METALLURGY DEV +1

A kind of waterproof and thermal insulation exterior wall paint for building and preparation method thereof

ActiveCN112251098BOvercoming the defects of being hot, sticky and brittleRetain alkali resistanceCoatingsFiberActivated carbon

The invention discloses a waterproof and thermal insulation exterior wall coating for buildings and a preparation method thereof. Auxiliaries, wherein the adjuvants include dispersants, wetting agents, thickeners, defoamers, film-forming aids and antifreezing agents. The preparation method of the waterproof and thermal insulation exterior wall coating for buildings comprises the following steps: firstly mix the silica sol, activated carbon fiber powder and titanium dioxide, then add the fluorosilicon modified acrylic emulsion and the graphene-acrylic composite emulsion to mix evenly, then add the auxiliary Agent mixing, and finally mixed with fluorosilane. The waterproof and thermal insulation exterior wall coating for buildings has excellent waterproof and thermal insulation properties, self-cleaning and washable, and is suitable for various external environments.

Owner:王洪磊

Preparation method of high-quality ceramic flat plate

The invention belongs to the field of ceramics, and particularly relates to a preparation method of a high-quality ceramic flat plate, which comprises the following steps: adding POSS (Polyhedral Oligomeric Silsesquioxane) into hydrochloric acid, carrying out ultrasonic treatment for 20-30 minutes, taking out a precipitate, putting the precipitate into a sodium hydroxide solution, carrying out microwave treatment for 1-2 hours, taking out, washing and drying to obtain hydroxylated POSS; the preparation method comprises the following steps: adding aluminum isopropoxide into ethanol, uniformly stirring to form a dissolving solution, putting hydroxylated POSS into the dissolving solution, carrying out low-temperature microwave treatment for 20-30 minutes, carrying out constant-temperature treatment for 30-50 minutes to form a concentrated solution, taking out the concentrated solution, naturally airing the concentrated solution, and carrying out heating treatment to obtain aluminoxyl modified POSS; carrying out ball milling on nano aluminum oxide, aluminoxyl modified POSS, methyl cellulose and an ethanol water solution, and carrying out constant-temperature treatment for 20-30 minutes to obtain slurry; carrying out vacuum stirring and defoaming on the slurry, and then carrying out tape casting and preliminary sintering to obtain a ceramic green body; coating the surface of the ceramic green body with silicon-aluminum liquid, coating the surface with aluminum foil after drying, carrying out microwave treatment for 20-40 minutes, and cooling and standing to obtain a pretreated flat plate; and carrying out presintering treatment on the pretreated flat plate for 1-2 hours, and carrying out isostatic pressing treatment for 2-5 hours to obtain the high-quality ceramic flat plate.

Owner:无锡特科精细陶瓷有限公司

Hexadecafluoro-1-octene modified polyperfluoroethylene propylene resin and its solution polymerization preparation method

Owner:JUHUA GROUP TECH CENT

A kind of high weather resistance waterproof exterior wall paint for building and preparation method thereof

ActiveCN112251094BOvercoming the defects of being hot, sticky and brittleRetain alkali resistanceAnti-corrosive paintsEpoxyPolymer science

Owner:徐洪涛

PVC aeration modified slipper and manufacturing method of the same

InactiveCN100528019CSolve the problem of uneven foamingEasy to recycleFootwearPlasticizerPolyvinyl chloride

Owner:黄世海

Hexadecafluoro-1-octene modified polyperfluoroethylene propylene resin and its bulk polymerization preparation method

The invention discloses hexadecafluoro-1-octene modified fluorinated ethylene-propylene resin and a bulk polymerization preparation method thereof. The method includes the steps that tetrafluoroethylene, hexafluoropropylene and hexadecafluoro-1-octene serve as comonomers, the comonomers are pre-added into a reactor under a certain temperature, the temperature is increased to 20-60 DEG C, the pressure is 1.1-1.5 MPa, a perfluoro initiator is added to initiate a polymerization reaction, a certain quantity of comonomers are replenished in the reaction process, and modified fluorinated ethylene-propylene is obtained finally. According to the method, the adopted modified monomers are perfluoro monomers, the obtained modified fluorinated ethylene-propylene resin is excellent in heat resistance, granules of the modified fluorinated ethylene-propylene resin are free of color staining, and the modified fluorinated ethylene-propylene resin can serve as a high-speed extrusion-grade product and can be stably smeared on the surface of a cable at the high speed of 300-500 m / min.

Owner:JUHUA GROUP TECH CENT

Direct-casting type anti-track agent and preparation method

ActiveCN102585522BImprove plasticityHigh modulus at room temperatureBuilding insulationsPolyesterWax

The invention discloses a direct-casting type anti-track agent, which is formed by the following components by weight in mixing mode: 20 to 40 parts of regenerative polyolefine plastic, 10 to 20 parts of regenerative polyester plastic, 2 to 10 parts of regenerative wax, 2 to 10 parts of organic powder body with small particle size and 5 to 10 parts of gilsonite. A preparation method of the direct-casting type anti-crack agent and a method for preparing asphalt mixture by adopting the direct-casting type anti-crack agent are further disclosed. Particles of the direct-casting type anti-crack agent can be directly cast in hot aggregate on construction sites to be mixed with the hot aggregate in drying mode, intermittent construction can be conducted, and the direct-casting type anti-track agent lowers or reduces probability of separation of modified asphalt in the cooling, transporting and storing processes, and break through limit and restraint brought by continuous production and construction.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

A kind of preparation method of soluble sugar frame rice protein

ActiveCN109123065BChange structureTo achieve the modified effectVegetable proteins working-upBiotechnologyCellulose

The invention discloses a preparation method for rice protein with high solubility and a sugar frame structure. Rice protein, carboxymethyl cellulose (sodium), pectin, Arabic gum, sodium alginate, xanthan gum, chitosan or compound polysaccharide of the rice protein are dissolved in an alkaline solution, stirred, neutralized and centrifuged, and after supernate is frozen and dried, soluble sugar frame rice protein is obtained. The sugar frame technology makes the solubility of the rice protein improved by 40 times or above to 70% or above, the emulsibility is improved to 300% or above, the foaming performance is improved by 500% or above, and the application prospect of the rice protein is greatly expanded.

Owner:JIANGNAN UNIV

Hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and emulsion polymerization preparation method thereof

The invention discloses a hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and an emulsion polymerization preparation method thereof. The method comprises the following steps: adding deionized water accounting for 50-70% of total volume into a reactor with a stirrer; replacing until oxygen content is qualified, adding an emulsifier or other aids, tetrafluoroethylene, hexafluoropropylene and hexadecafluoro-1-octene and other pre-added copolymerizable monomers; starting to stir and raising the temperature to 60-120 DEG C, controlling the reaction pressure to be 2-5MPa, adding an initiator, supplementing a certain amount of copolymerizable monomers so as to obtain polymer emulsion; and condensing, washing and drying the emulsion, thereby obtaining the modified polyperfluoro ethylene-propylene resin. According to the method disclosed by the invention, the hexadecafluoro-1-octene modified monomer serves as a perfluoro monomer, the prepared modified polyperfluoro ethylene-propylene resin is excellent in heat resistance, does not have an aggregate dyeing phenomenon, can serve as a high-speed extrusion grade product, and can be stably coated onto the cable surface at a high speed of 300-500m / min.

Owner:JUHUA GROUP TECH CENT

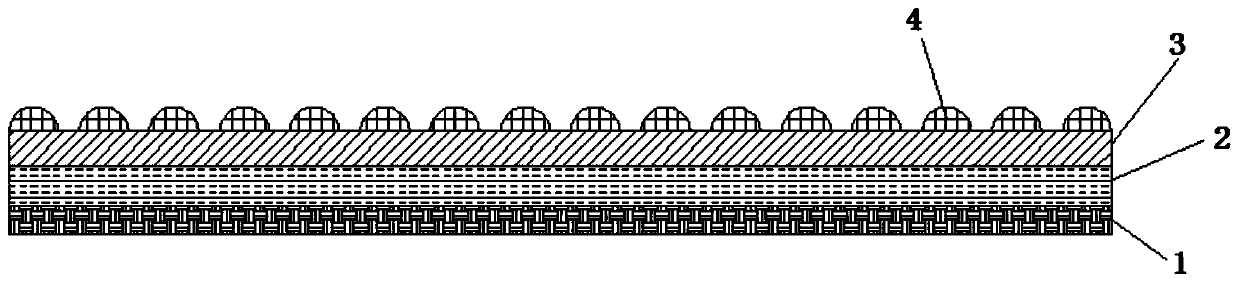

A wear-resistant plastic packaging bag and its processing technology

ActiveCN109159484BAchieve complexCompositeBag making operationsBio-packagingPolymer sciencePlastic packaging

Disclosed are a wear-resistant plastic packaging bag and a process for processing same. The packaging bag comprises an inner environmentally-friendly substrate layer (1), a middle interlayer (2) and an outer wear-resistant layer (3), wherein wear-resistant protrusions (4) are further uniformly distributed on a surface of the wear-resistant layer (3), the wear-resistant layer (3) and the wear-resistant protrusions (4) are both made from a special wear-resistant material, and the wear-resistant layer (3) is integrally formed with the wear-resistant protrusions (4). The processing process comprises: a step S1 of preparing the environmentally-friendly substrate layer (1); a step S2 of preparing the wear-resistant layer (3) and the wear-resistant protrusions (4); a step S3 of preparing a plastic film; and a step S4 of cutting, edge heat sealing and processing by stamping to obtain a wear-resistant plastic packaging bag. The environmentally-friendly substrate layer (1) of the plastic packaging bag is made from polylactic acid, and the production process for polylactic acid is pollution-free, moreover, the product is biodegradable, nontoxic to human bodies and environmentally friendly, and food can be stored therein. The outer wear-resistant layer (3) has an excellent wear-resistant effect, can prolong the service life of the plastic packaging bag and has low production costs.

Owner:温州市宏科印业有限公司

High-weather-resistance waterproof exterior wall coating for buildings and preparation method thereof

ActiveCN112251094AOvercoming the defects of being hot, sticky and brittleRetain alkali resistanceAnti-corrosive paintsEpoxyWeather resistance

The invention discloses a high-weather-resistance waterproof exterior wall coating for buildings and a preparation method thereof, the coating comprises the following components: a fluorosilicone modified acrylic emulsion, an epoxy modified acrylic emulsion, fluorosilane, organic bentonite, silicon oxide, titanium dioxide and an auxiliary agent, and the auxiliary agent comprises a dispersant, a wetting agent, a thickener, a defoamer, a coalescing agent and an antifreezing agent. The preparation method comprises the following steps: uniformly mixing the organic bentonite, the silicon oxide andthe titanium dioxide, adding the fluorosilicone modified acrylic emulsion and the epoxy modified acrylic emulsion, uniformly mixing, adding the auxiliary agent, uniformly mixing, and finally adding the fluorosilane. According to the high-weather-resistance waterproof exterior wall coating for the building and the preparation method thereof, the waterproof performance is excellent, and the coatingis self-cleaning, washable and suitable for various external environments.

Owner:徐洪涛

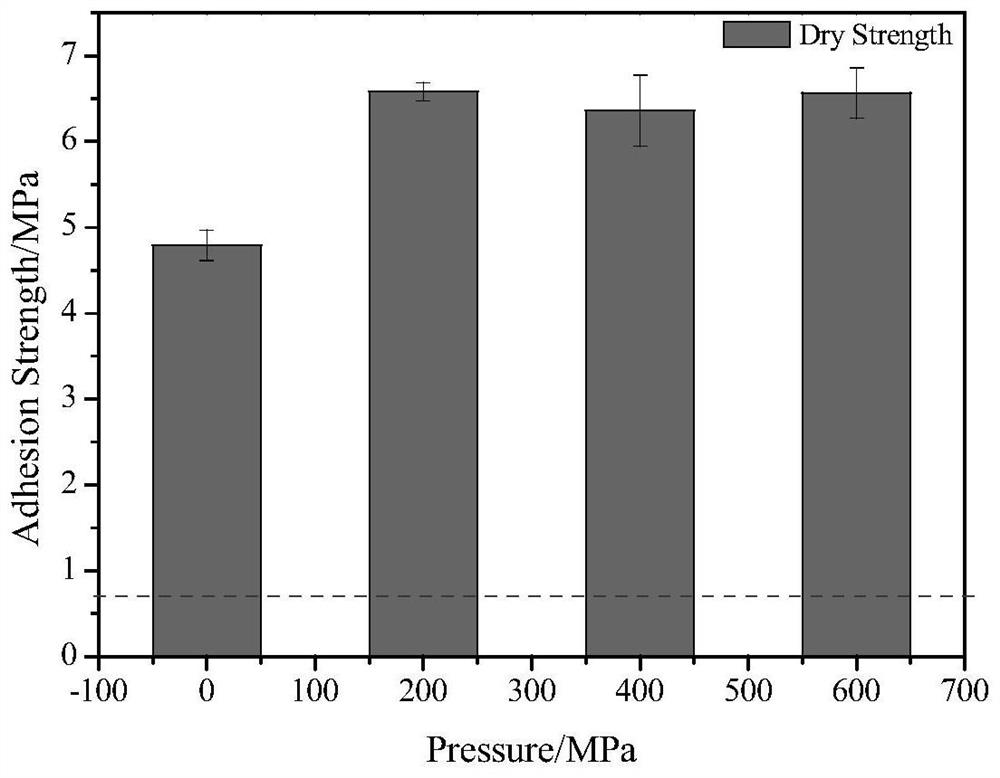

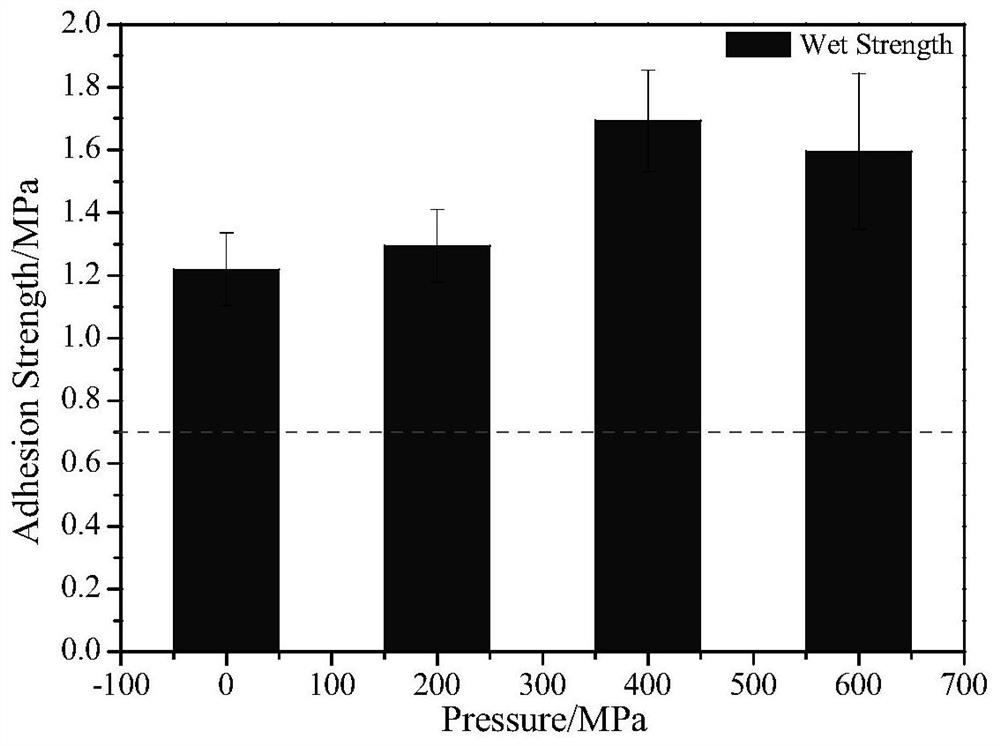

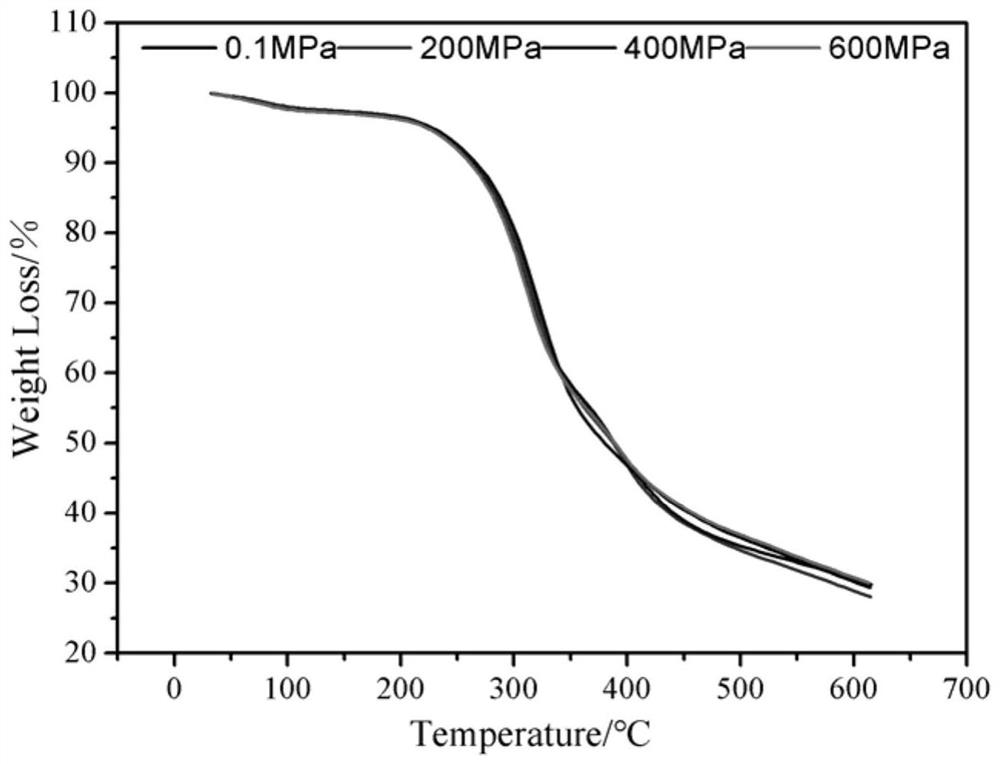

A preparation method of rapeseed protein adhesive based on ultra-high pressure and egde composite modification

ActiveCN111978917BTo achieve the modified effectAchieving no aldehyde release effectProtein adhesivesPeptide preparation methodsProtein solutionAdhesive

The invention discloses a method for preparing a rapeseed protein adhesive compound modified based on ultra-high pressure technology and EGDE. First extract rapeseed protein from rapeseed meal, then disperse the extracted protein evenly in water, then subject the dispersed protein solution to ultra-high pressure treatment, and then add EGDE to the processed protein solution in proportion, Finally, NaOH was used to adjust the pH, and finally a rapeseed protein adhesive with no aldehyde and excellent water resistance was prepared. The rapeseed protein adhesive synthesized by ultra-high pressure and EGDE modification of the present invention exhibits excellent adhesive performance and water resistance, improves cohesive interaction, and forms a dense cross-linked network. The adhesive prepared by the invention has better wettability and lower viscosity, and significantly improves the dry and wet bonding strength of the adhesive.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com