Vector processing technology

A processing technology and carrier technology, which is applied in the field of microbial carriers, can solve the problems of affecting the efficiency of microbial cultivation, the bottleneck of microbial cultivation efficiency, and the difficulty of microorganisms to attach, so as to achieve the effects of convenient cultivation, cost reduction, and improved sewage treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

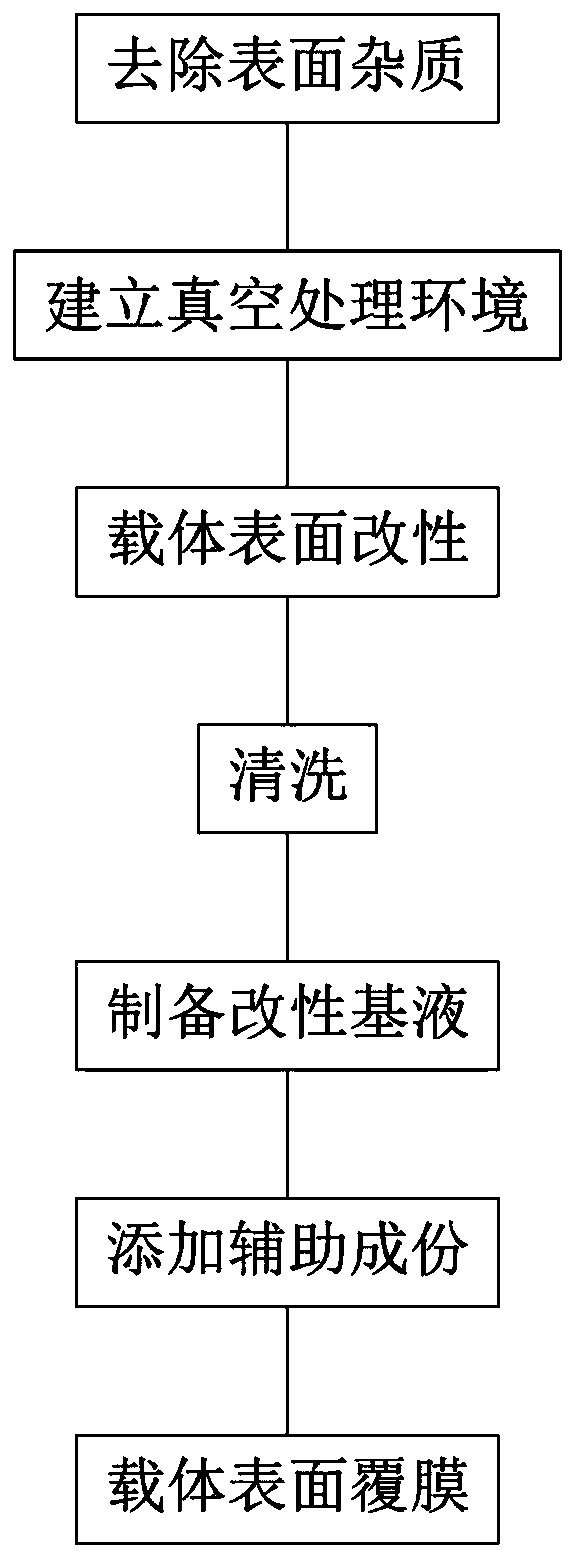

[0029] A carrier processing technology such as figure 1 shown, including the following steps:

[0030] S1. Remove surface impurities: remove impurities on the carrier, wash the carrier with distilled water and dry it;

[0031] S2. Establish a vacuum processing environment: place the carrier in a closed processing chamber, and use a vacuum pump to extract the air in the processing chamber to form a vacuum environment;

[0032] S3. Carrier surface modification: set an electrode on both sides of the carrier, inject argon and oxygen into the processing chamber, and pass an alternating current with a working frequency of 10Mhz to the two electrodes, and the electric field generated by the argon and oxygen on the two electrodes Energy is obtained in the medium and plasma is formed. The plasma moves with the change of the electric field and collides with the carrier, breaking the chemical bond of the polymer on the carrier surface and forming free radicals. The free radicals react w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com