Surface modification method for wool

A surface modification and surfactant technology, applied in the field of wool modification, can solve the problems of limited wool modification, no wool modification, insufficient wool keratin effect, etc., and achieve the effect of no AOX emission and residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

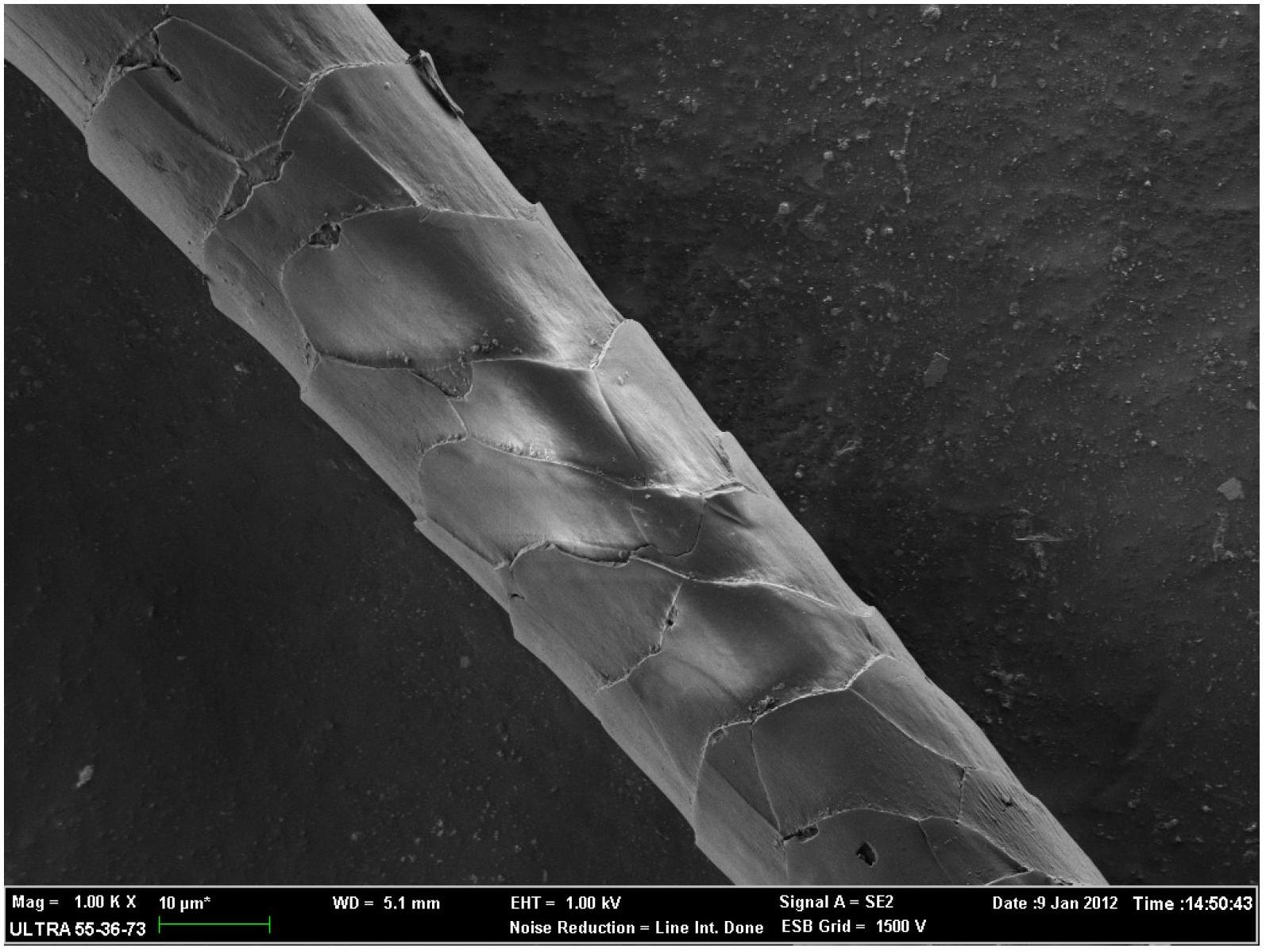

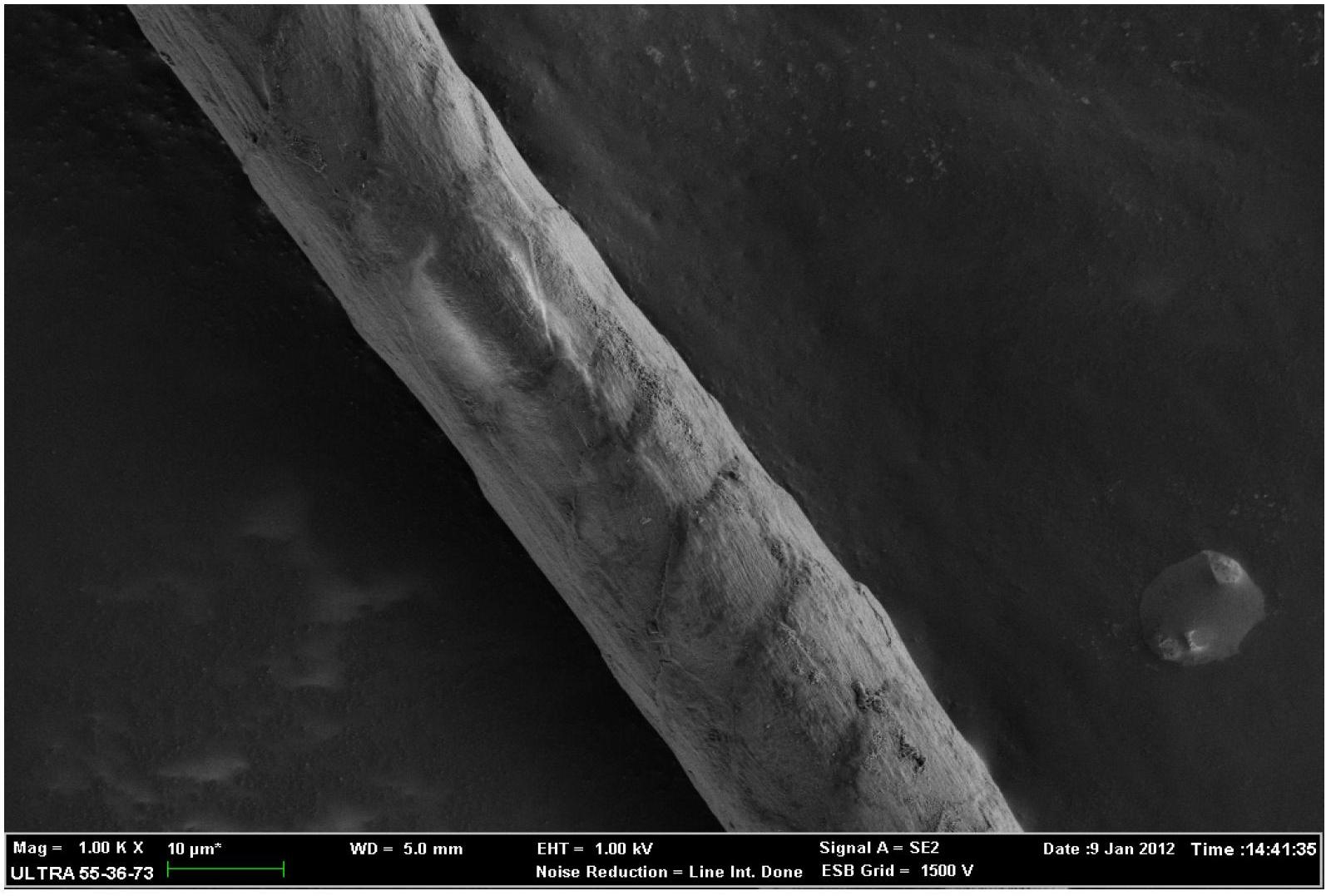

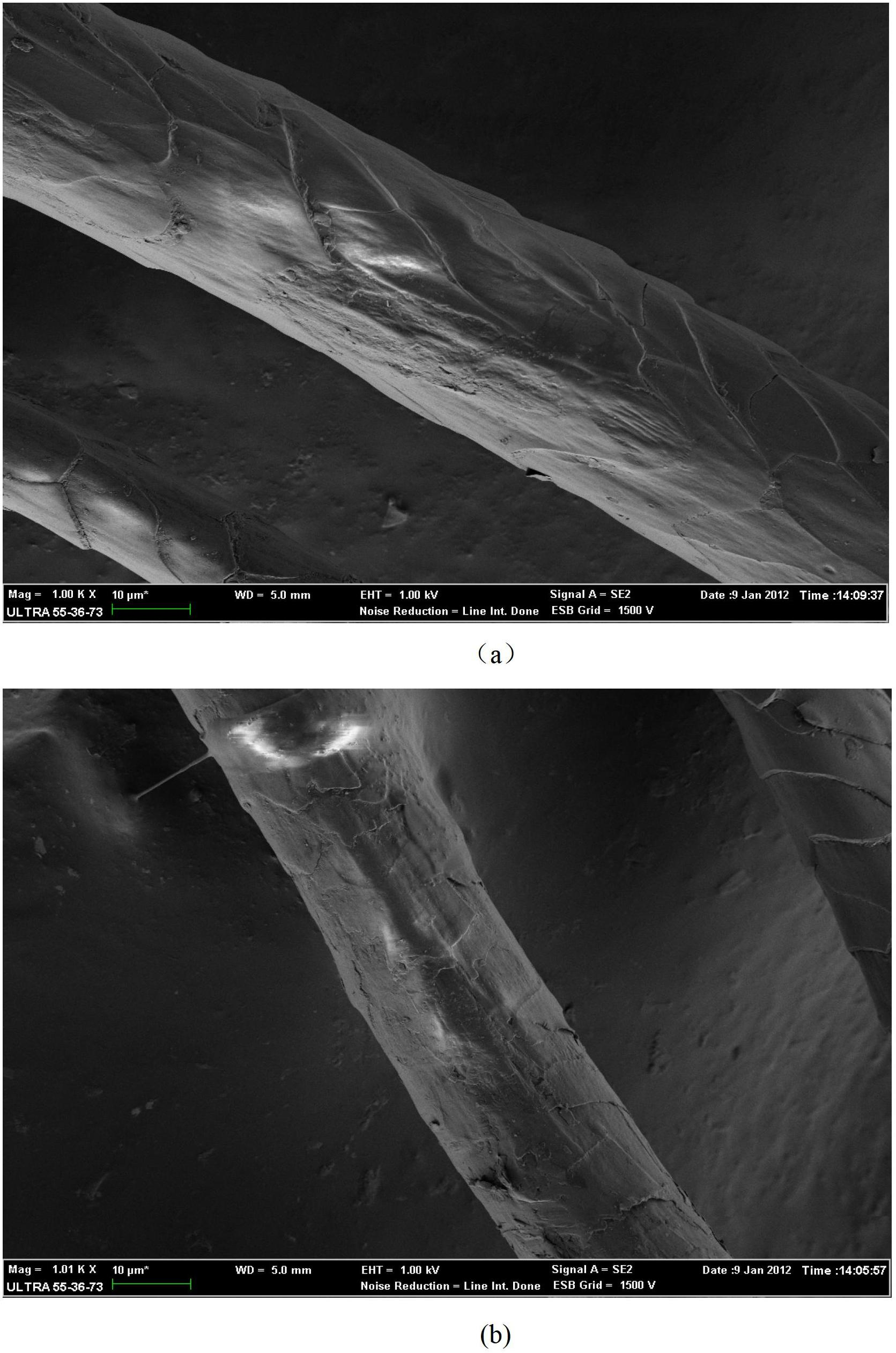

Image

Examples

Embodiment 1

[0041] Embodiment 1, a method for surface modification of wool, using wool fiber (i.e. wool loose fiber) as wool to be treated, the following steps are carried out successively:

[0042] 1) Add anatase TiO to the dispersant MF aqueous solution (as a solvent) with a concentration of 1.0g / L 2 Nanoparticles, anatase TiO 2 Aqueous dispersion of nanoparticles; the anatase TiO 2 Anatase TiO in Nanoparticle Aqueous Dispersion 2 The concentration of nanoparticles was 10 g / L.

[0043] According to every 1g wool fiber corresponds to 1ml titanium ore type TiO 2 The ratio of the nanoparticle aqueous dispersion; the above-mentioned anatase TiO2 The nanoparticle aqueous dispersion is evenly sprayed on the wool fiber; the wool fiber is evenly mixed during the spraying process; thus the anatase TiO 2 The nanoparticles are evenly attached to the wool fiber surface. At this time, the amount of liquid carried by the wool fiber is about 100% (that is, the weight of the wool fiber has doubled...

Embodiment 2

[0050] Embodiment 2, a method for surface modification of wool, using wool fiber (wool loose fiber) as wool to be treated, the following steps are carried out successively:

[0051] 1) Add anatase TiO to the dispersant HT-5000 aqueous solution with a concentration of 1.5g / L 2 Nanoparticles, anatase TiO 2 Aqueous dispersion of nanoparticles, the anatase TiO 2 Anatase TiO in Nanoparticle Aqueous Dispersion 2 The concentration of nanoparticles was 8 g / L.

[0052] 30ml of anatase TiO per 1g of wool fiber 2 Ratio of aqueous dispersion of nanoparticles; pour anatase TiO in a large tank 2 Aqueous dispersion of nanoparticles, in which the wool fiber is soaked; soaking time is 30 minutes; the wool fiber is slightly evenly stirred during the soaking process; after soaking, the excess TiO is squeezed out with a paddle car 2 Nanoparticle dispersion (i.e. anatase TiO 2 nanoparticle aqueous dispersion), so that the amount of liquid carried by the wool fiber is 100% (that is, the weigh...

Embodiment 3

[0057] Embodiment 3, a method for surface modification of wool, the following steps are carried out after step 3) of embodiment 1:

[0058] Add 3% silk fibroinase (the silk fibroin enzyme Savinase 4.0T from Novozymes) to the water to obtain an aqueous solution of silk fibroin enzyme, the weight of which is about 3% by weight of the original wool fiber to be treated. 2 to 4 times the weight of the wool fiber as the product to be treated;

[0059] Put the wool fiber obtained in step 3) into the above-mentioned silk fibroin aqueous solution, adjust the pH to 8.5 with sodium carbonate, and soak at 45°C for 50 minutes;

[0060] Then carry out inactivation, specifically: adjust the pH to 4.5 with formic acid or acetic acid, and treat at 80°C for 10 minutes, so as to inactivate silk protease, and then wash with water for 2 times; The wool fiber of the treated product is 10 to 100 times, for example, 50 times; after each washing, conventional dehydration treatment is carried out. At...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com