A preparation method of rapeseed protein adhesive based on ultra-high pressure and egde composite modification

A compound modification and rapeseed technology, which is applied in the preparation method of peptides, the preparation of animal glue or gelatin, and protein adhesives, etc., can solve the problems of poor water resistance and formaldehyde release of adhesives, and achieve bonding performance and Excellent water resistance, improved water resistance and bonding strength, and the effects of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

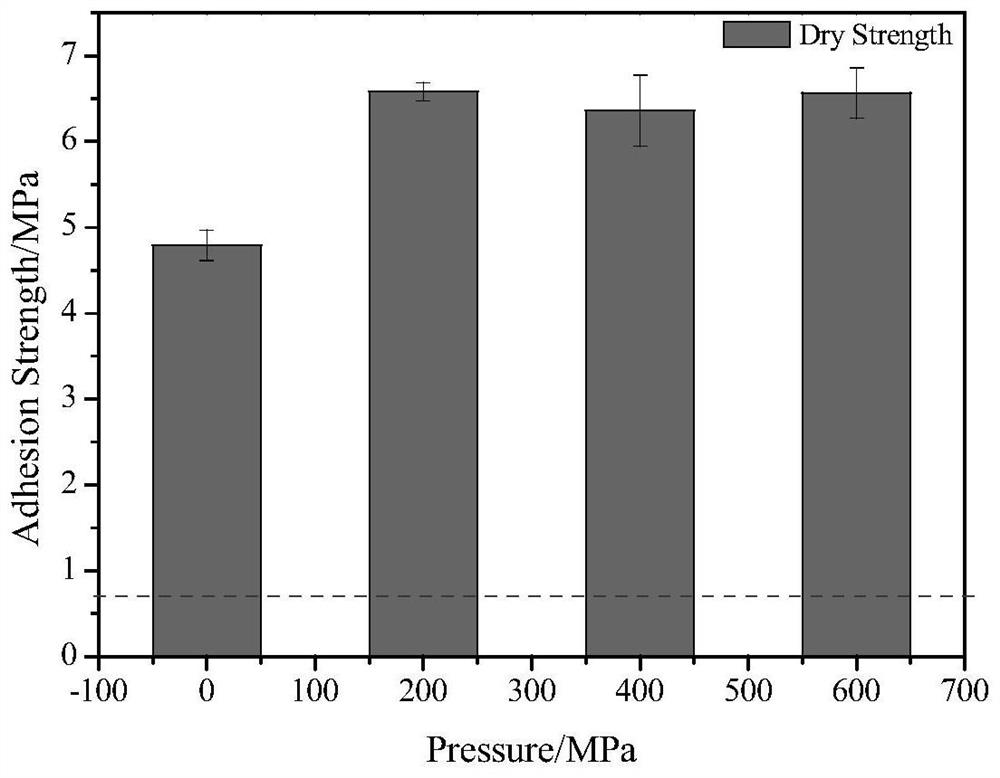

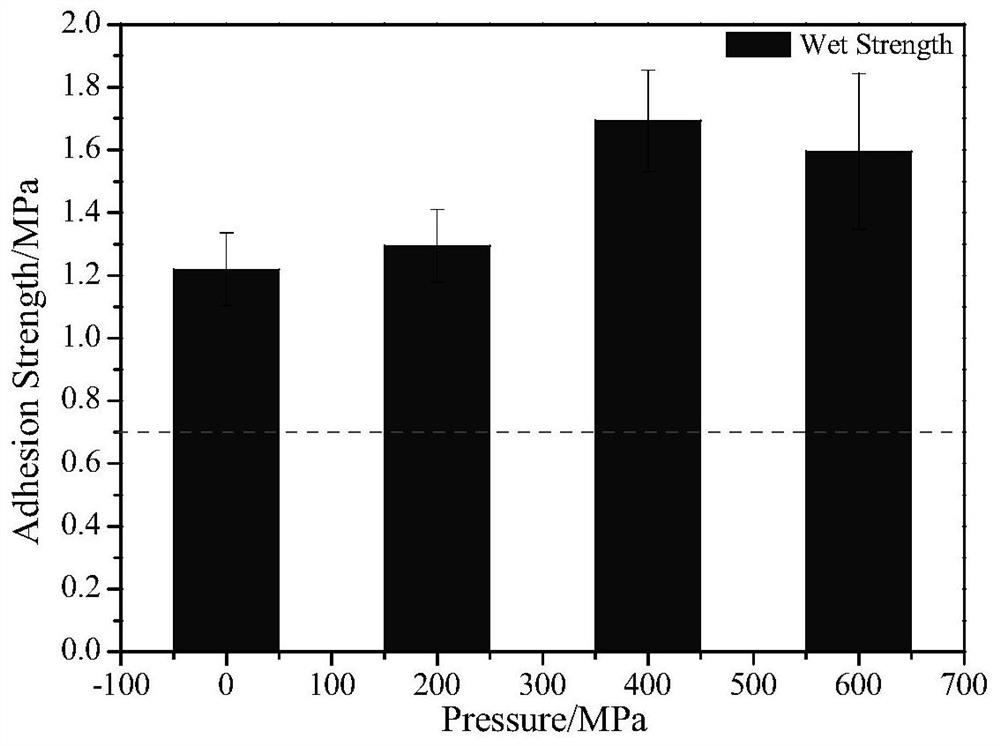

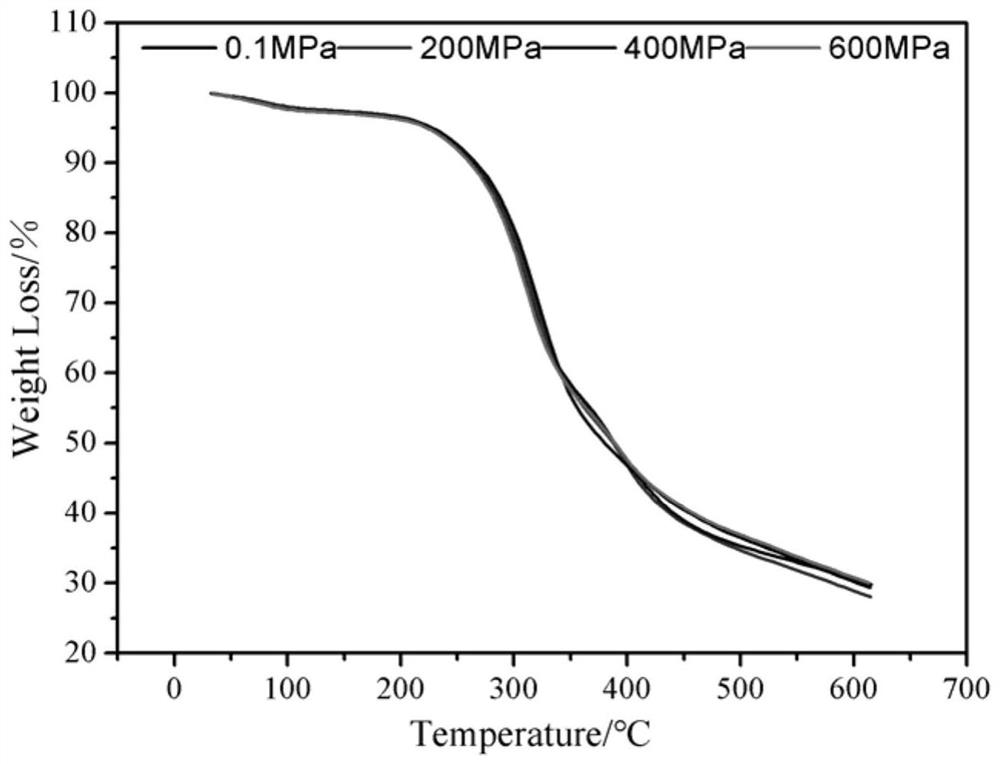

Embodiment 1

[0038] Take 1.5g of rapeseed protein, add 20mL of ultra-pure water, stir at room temperature at a rate of 500r / min for about 2 hours to fully disperse the protein in water, then transfer the pretreated rapeseed protein mixture to a 6# polyethylene plastic bag In , mark the sample as 3, heat seal the sample with a vacuum heat sealer, the vacuum time is 25s, the heat sealing time is 2s, and the heat sealing temperature is 60°C. After the processed sample was treated at 200MPa for 15min, it was transferred to a 25mL beaker, labeled accordingly, and 0.1g of ethylene glycol diglycidyl ether (EGDE) was added to the protein mixture and stirred for 1.5h, then adjusted with 6mol / L NaOH Rapeseed protein adhesive was obtained when the pH was adjusted to 9.

Embodiment 2

[0040] Take 1.5g of rapeseed protein, add 20mL of ultra-pure water, stir at room temperature at a rate of 500r / min for about 2 hours to fully disperse the protein in water, then transfer the pretreated rapeseed protein mixture to a 6# polyethylene plastic bag In , mark the sample as 4, heat seal the sample with a vacuum heat sealer, the vacuum time is 25s, the heat sealing time is 2s, and the heat sealing temperature is 60°C. After the processed sample was treated at 400MPa for 15min, it was transferred to a 25mL beaker, labeled accordingly, and 0.1g of ethylene glycol diglycidyl ether (EGDE) was added to the protein mixture and stirred for 1.5h, then adjusted with 6mol / L NaOH Rapeseed protein adhesive was obtained when the pH was adjusted to 9.

Embodiment 3

[0042] Take 1.5g of rapeseed protein, add 20mL of ultra-pure water, stir at room temperature at a rate of 500r / min for about 2 hours to fully disperse the protein in water, then transfer the pretreated rapeseed protein mixture to a 6# polyethylene plastic bag In , mark the sample as 5, heat seal the sample with a vacuum heat sealer, the vacuum time is 25s, the heat sealing time is 2s, and the heat sealing temperature is 60°C. After the processed sample was treated at 600MPa for 15min, it was transferred to a 25mL beaker, labeled accordingly, and 0.1g of ethylene glycol diglycidyl ether (EGDE) was added to the protein mixture and stirred for 1.5h, then adjusted with 6mol / L NaOH Rapeseed protein adhesive was obtained when the pH was adjusted to 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com