A wear-resistant plastic packaging bag and its processing technology

A packaging bag and plastic technology, which is applied in packaging, bio-packaging, transportation and packaging, etc., can solve the problems of plastic packaging bag materials that are not healthy and environmentally friendly, cannot store food, and have a simple structure, and achieve high hardness, increased density, and improved The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

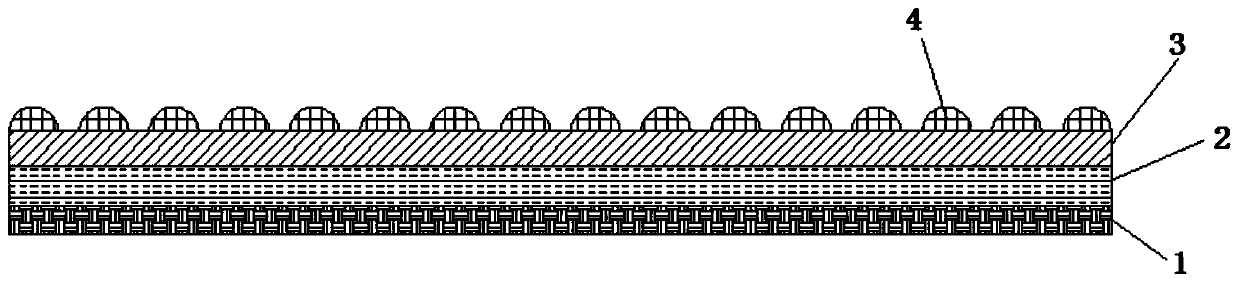

[0051] Step S1, preparation of environmentally friendly substrate layer 1: put polylactic acid into a film blowing machine, adjust the temperature of the film blowing machine to 200-220°C, and blow the film to form an environmentally friendly substrate layer 1;

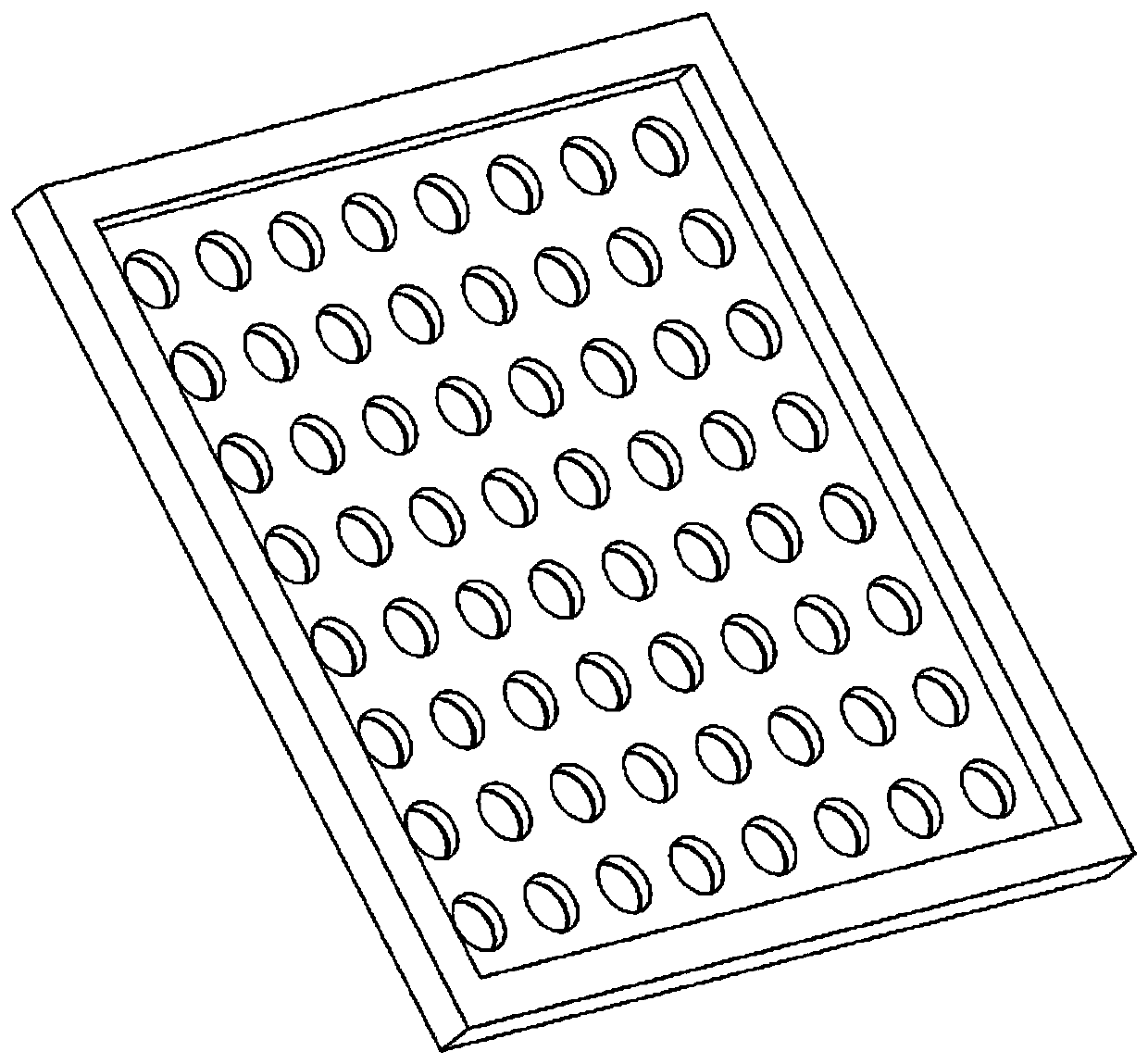

[0052] Step S2, preparation of the wear-resistant layer 3 and the wear-resistant protrusion 4: mix the modified silicone resin, hydroxy silicone oil, sol, boehmite, and tetraethylammonium benzoate according to the ratio, and place in such figure 2 In the mold shown, the mold is placed between a flat hydraulic press for lamination. The lamination temperature is 45°C, the constant pressure is 0.6MPa, and the pressure is maintained for 45-50s. Take it out and cool it at normal temperature and pressure to obtain an integrally formed wear-resistant layer 3 and wear-resistant protrusions 4;

[0053] Step S3, mix the nano-titanium dioxide and the acrylic adhesive according to the mass ratio of 1:0.8-1 evenly, place it in th...

Embodiment 1

[0056] A wear-resistant plastic packaging bag, comprising an inner environmental-friendly substrate layer, a middle interlayer and an outer wear-resistant layer, wherein the surface of the wear-resistant layer is evenly distributed with wear-resistant protrusions, and the wear-resistant layer and the wear-resistant protrusions They are all made of special wear-resistant materials, and the wear-resistant layer and the wear-resistant protrusions are integrally formed;

[0057] The environmental protection substrate layer is made of polylactic acid, and the thickness of the environmental protection substrate layer is 0.15mm;

[0058] The interlayer is made of nano-titanium dioxide, and the thickness of the interlayer is 0.3mm;

[0059] The thickness of the wear-resistant layer is 0.3mm;

[0060] The wear-resistant protrusion is in the shape of a hemisphere, the arc surface of the hemisphere faces outward, and the diameter of the hemisphere is 0.05mm;

[0061] The special wear-r...

Embodiment 2

[0063] A wear-resistant plastic packaging bag, comprising an inner environmental-friendly substrate layer, a middle interlayer and an outer wear-resistant layer, wherein the surface of the wear-resistant layer is evenly distributed with wear-resistant protrusions, and the wear-resistant layer and the wear-resistant protrusions They are all made of special wear-resistant materials, and the wear-resistant layer and the wear-resistant protrusions are integrally formed;

[0064] The environmental protection substrate layer is made of polylactic acid, and the thickness of the environmental protection substrate layer is 0.2mm;

[0065] The interlayer is made of nano-titanium dioxide, and the thickness of the interlayer is 0.4mm;

[0066] The thickness of the wear-resistant layer is 0.35mm;

[0067] The wear-resistant protrusion is in the shape of a hemisphere, the arc surface of the hemisphere faces outward, and the diameter of the hemisphere is 0.06mm;

[0068] The special wear-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com