Self-repairing aramid fiber reinforcing core for optical cable and preparation method thereof

An aramid fiber reinforced and self-healing technology, applied in the field of optical cables and optical cable materials, can solve the problems of poor interface adhesion, lack of active functional groups, and poor wettability of aramid fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

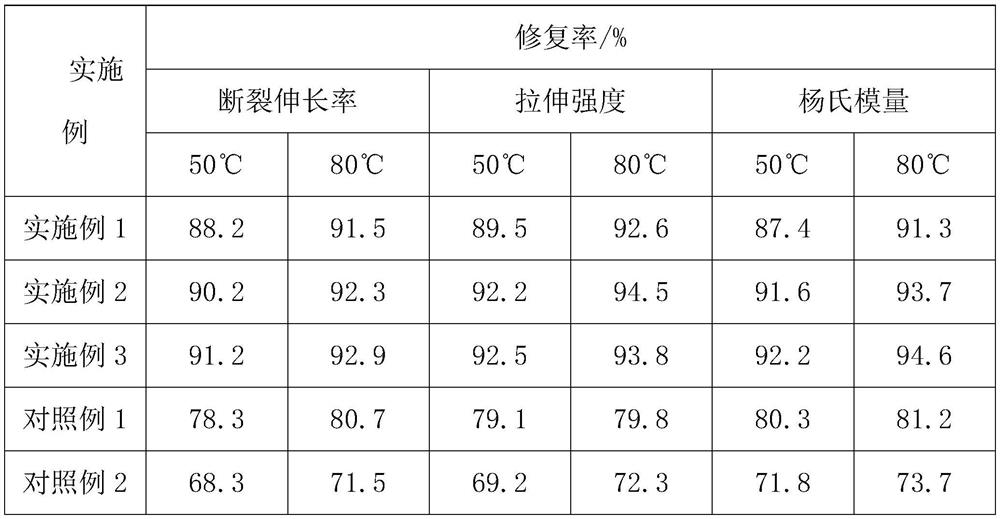

Embodiment 1

[0029] A self-repairing aramid fiber reinforced core for optical cable, comprising an aramid fiber substrate, a polydopamine layer on the surface of the aramid fiber substrate, and a polyurethane layer coated on the surface of the polydopamine layer; the polyurethane layer is doped with boron nitride nanosheets ; The content of boron nitride nanosheets in the polyurethane layer is 5wt%; the thickness of the polyurethane layer is 0.5mm;

[0030] The polyurethane in the polyurethane layer is self-healing polyurethane, and the preparation process of self-healing polyurethane includes:

[0031] S1. Mix diphenylmethane diisocyanate and poly-1,4-butylene adipate diol in a molar ratio of 1.8:1, add DMF to dissolve, heat up to 70°C for 3 hours in a nitrogen atmosphere, and cool down to 0°C; add furfurylamine dropwise to react for 2 hours, raise the temperature to 30°C, continue to react for 4 hours, precipitate and filter to obtain a furan-terminated intermediate; wherein, the molar v...

Embodiment 2

[0038] A self-repairing aramid fiber reinforced core for optical cable, comprising an aramid fiber substrate, a polydopamine layer on the surface of the aramid fiber substrate, and a polyurethane layer coated on the surface of the polydopamine layer; the polyurethane layer is doped with boron nitride nanosheets ; The content of boron nitride nanosheets in the polyurethane layer is 15wt%; the thickness of the polyurethane layer is 3mm;

[0039] The polyurethane in the polyurethane layer is self-healing polyurethane, and the preparation process of self-healing polyurethane includes:

[0040] S1. Mix diphenylmethane diisocyanate and poly-1,4-butylene adipate diol in a molar ratio of 2.2:1, add DMF to dissolve, heat up to 80°C for 2 hours in a nitrogen atmosphere, and cool down to 5°C; add furfurylamine dropwise for 1 hour, raise the temperature to 40°C, continue the reaction for 3 hours, precipitate and filter to obtain a furan-terminated intermediate; wherein, the molar volume r...

Embodiment 3

[0047] A self-repairing aramid fiber reinforced core for optical cable, comprising an aramid fiber substrate, a polydopamine layer on the surface of the aramid fiber substrate, and a polyurethane layer coated on the surface of the polydopamine layer; the polyurethane layer is doped with boron nitride nanosheets ; The content of boron nitride nanosheets in the polyurethane layer is 10wt%; the thickness of the polyurethane layer is 2mm;

[0048] The polyurethane in the polyurethane layer is self-healing polyurethane, and the preparation process of self-healing polyurethane includes:

[0049] S1. Mix diphenylmethane diisocyanate and poly-1,4-butylene adipate diol in a molar ratio of 2:1, add DMF to dissolve, heat up to 75°C in a nitrogen atmosphere and react for 2.5h, then cool down to 3°C; add furfurylamine dropwise to react for 1.5h, raise the temperature to 35°C, continue to react for 3.5h, precipitate and filter to obtain a furan-terminated intermediate; wherein, the molar vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com