A method for catalytic oxidation modification of wool surface

A technology of surface catalysis and oxidation modification, which is applied in the fields of biochemical fiber treatment, textile and paper making, fiber treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

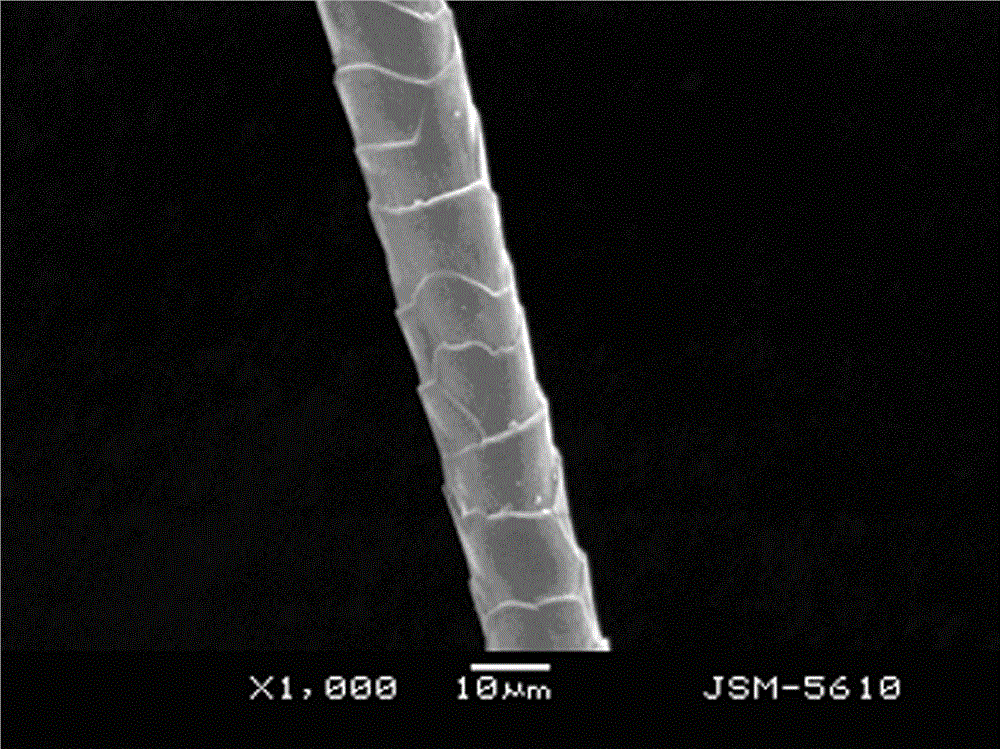

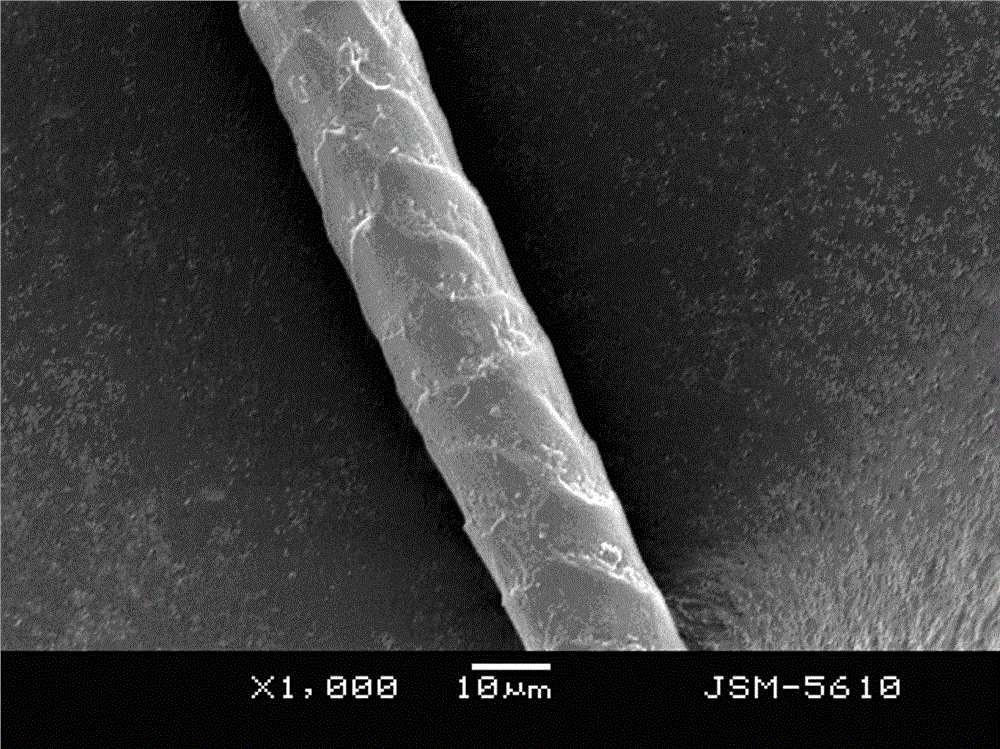

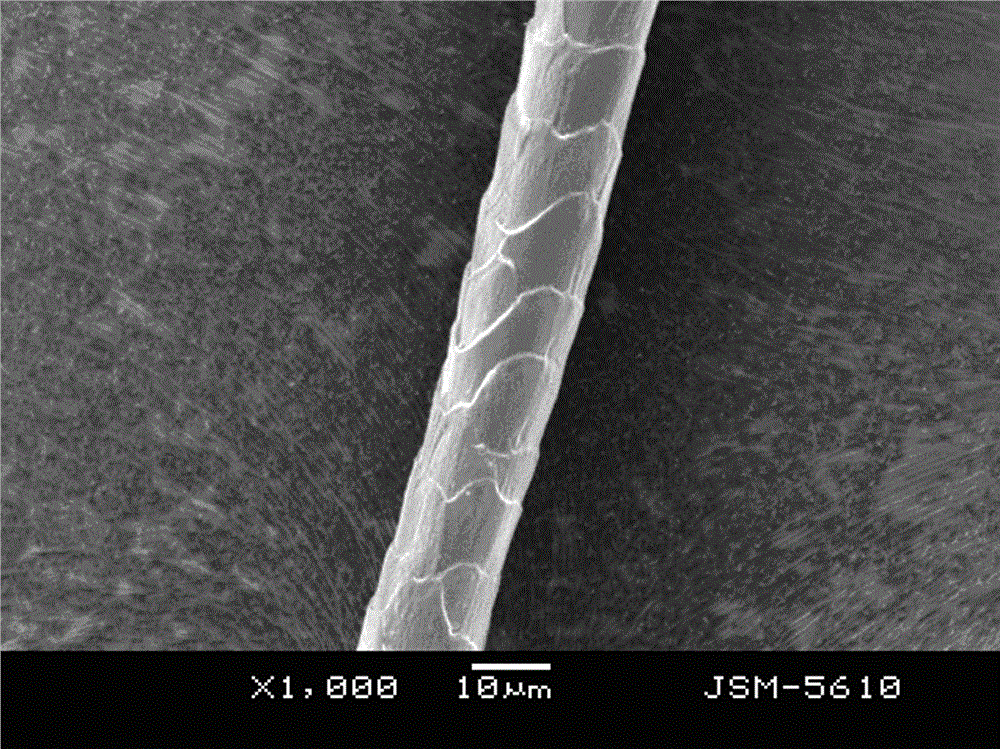

Image

Examples

Embodiment 1

[0044] A method for modifying the surface of wool by catalytic oxidation, using loose wool fibers as wool to be treated, and performing the following steps in sequence:

[0045] 1) Add iron oxide nanoparticles to the 1.0g / L dispersant MF aqueous solution (as a solvent) to prepare an aqueous dispersion of iron oxide nanoparticles; the concentration of iron oxide nanoparticles in the aqueous dispersion is 10g / L.

[0046] According to the ratio of every 1g of wool fiber corresponding to 1ml of iron oxide nanoparticle aqueous dispersion; the above-mentioned iron oxide nanoparticle aqueous dispersion is evenly sprayed on the wool fiber; during the spraying process, the wool fiber is evenly stirred; thereby making the iron oxide nanoparticle Evenly attached to the wool fiber surface. At this time, the amount of liquid carried by the wool fiber is about 100% (that is, the weight of the wool fiber has doubled). Iron oxide nanoparticles are attached to the surface of the wool fiber....

Embodiment 2

[0053] A method for modifying the surface of wool by catalytic oxidation, using wool tops as wool to be treated, and performing the following steps in sequence:

[0054] 1) Add iron oxide nanoparticles to the 1.0g / L dispersant H-423N aqueous solution (as a solvent) to prepare an aqueous dispersion of iron oxide nanoparticles; the concentration of iron oxide nanoparticles in the aqueous dispersion It is 15g / L.

[0055] Pour the aqueous dispersion of iron oxide nanoparticles into the wool ball dyeing machine, soak the wool tops for 30 minutes, and the bath ratio is 1:15; use a dehydrator to remove the excess iron oxide nano particle dispersions, so that the wool tops are more sensitive to iron oxide. The liquid-carrying rate of the nanoparticle aqueous dispersion is 100%, that is, the weight of the wool top is increased by 100%, so that the iron oxide nanoparticles are attached to the surface of the wool top. The wool is then dried at 100°C-120°C.

[0056] 2) Pour 30-50% H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com