Preparation method of nickel cobalt lithium manganate positive electrode material

A technology of nickel cobalt lithium manganate and positive electrode material, which is applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problem of lengthy preparation process of nickel cobalt lithium manganese oxide, etc., and achieves easy automatic control, less time-consuming, product pure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of nickel cobalt lithium manganese oxide cathode material of the present invention comprises the following steps:

[0028] (1) According to the molar ratio Li:Ni:Co:Mn:M=(1.0~1.1):x:y:z:η(0≤x, y, z≤1, 0≤η≤0.1 and x+y+ z+η=1) Weighing soluble salts of lithium, nickel, cobalt, manganese and doping elements respectively, and dissolving them in deionized water to form a precursor solution;

[0029] (2) Send the precursor solution to an ultrasonic spray device, atomize it into droplets with a size of 200nm-50μm, and form an aerosol with the carrier gas;

[0030] (3) Send the aerosol to the high-temperature pyrolysis device through the carrier gas for pre-calcination treatment at 800-1200°C for 2-10s, use the carrier gas to transport the pre-calcined intermediate product to the collection device, and collect the solid components to obtain pre-calcination product;

[0031] (4) Transfer the pre-calcined product to heat treatment equipment, and obtain ni...

Embodiment 1

[0036] The preparation method of the nickel cobalt lithium manganese oxide cathode material of the present embodiment comprises the following steps:

[0037] (1) Weigh the acetates of lithium, nickel, cobalt, and manganese respectively according to the molar ratio Li:Ni:Co:Mn=1.06:0.8:0.1:0.1, and dissolve them in deionized water to form a precursor solution;

[0038] (2) Using air as the carrier gas, the precursor solution is sent to an ultrasonic spray device, atomized into droplets with a size of 200nm-50μm, and combined with the carrier gas to form an aerosol;

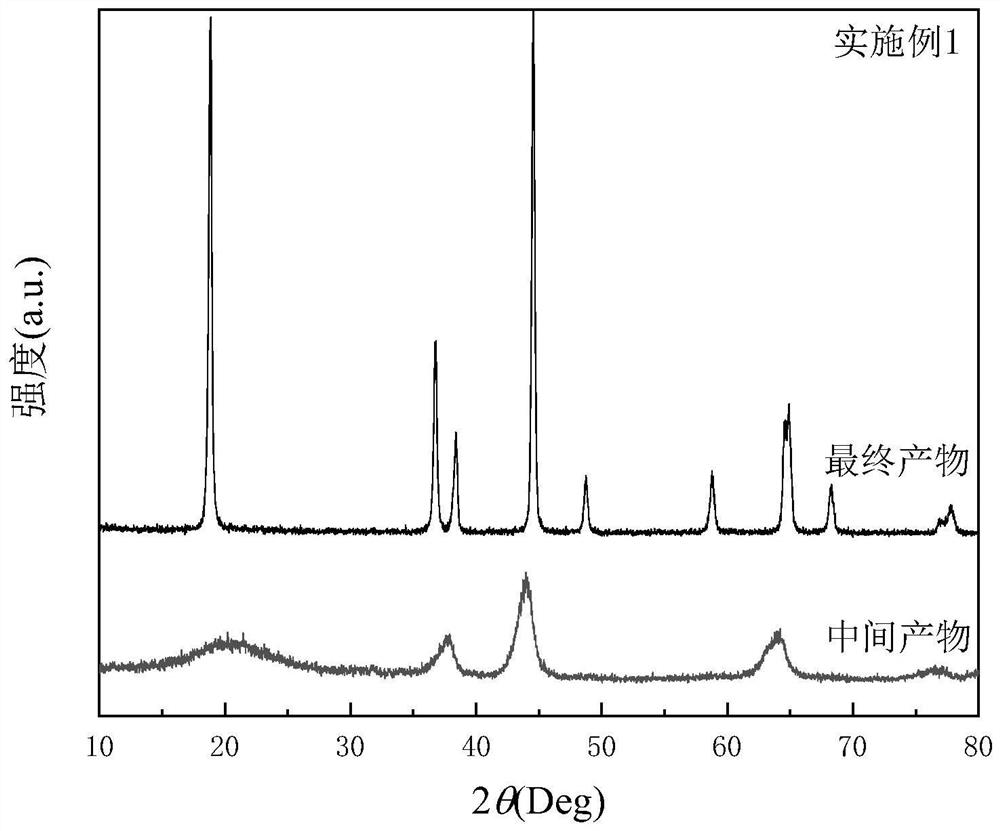

[0039] (3) Send the aerosol to the high-temperature pyrolysis device through the carrier gas for pre-calcination treatment at 900°C for 2s, use the carrier gas to transport the pre-calcined intermediate product to the collection device, and collect the solid component to obtain the pre-calcined product;

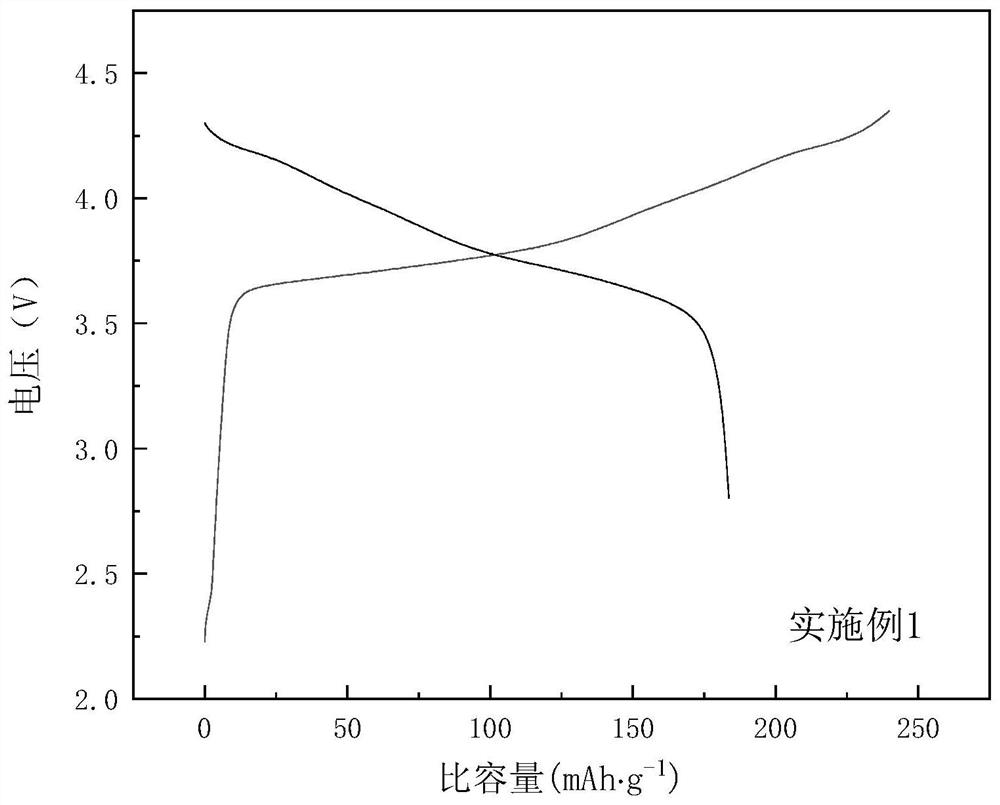

[0040] (4) Transfer the pre-calcined product to heat treatment equipment, and obtain lithium nickel cobalt mang...

Embodiment 2

[0042] The preparation method of the nickel cobalt lithium manganese oxide cathode material of the present embodiment comprises the following steps:

[0043] (1) Weigh the chlorides of lithium, nickel, cobalt, and manganese respectively according to the molar ratio Li:Ni:Co:Mn=1.02:0.8:0.1:0.1, and dissolve them in deionized water to form a precursor solution;

[0044] (2) Using oxygen as the carrier gas, the precursor solution is sent to the ultrasonic spray device, atomized into droplets with a size of 200nm-50μm, and combined with the carrier gas air to form an aerosol;

[0045] (3) Send the aerosol to the high-temperature pyrolysis device through the carrier gas for pre-calcination treatment at 900°C for 2s, use the carrier gas to transport the pre-calcined intermediate product to the collection device, and collect the solid component to obtain the pre-calcined product;

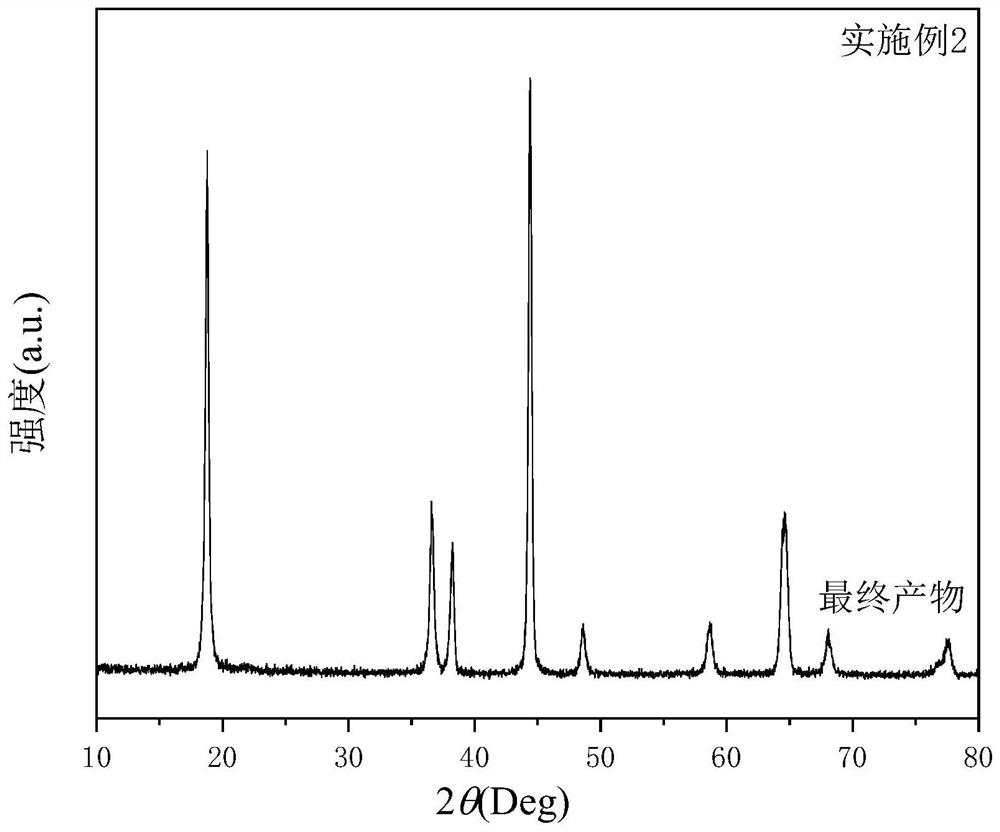

[0046] (4) Transfer the pre-calcined product to heat treatment equipment, and obtain lithium nickel co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com