Environment-friendly rubber asphalt with stable storage performance and preparation method of rubber asphalt

A rubberized asphalt, environmentally friendly technology, used in building insulation materials, building components, buildings, etc., can solve problems such as poor safety, high temperature, waste of production energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment is to prepare a kind of environment-friendly rubber asphalt with stable storage performance, and the specific operations are as follows:

[0038] Preheat Korean GS70# road petroleum asphalt to 120°C, then quickly exchange heat to 160°C through a heat exchanger, and pump it into the workshop reaction kettle; when the pumped Korean GS70# road petroleum asphalt reaches 3000kg, start stirring, At the same time, 300kg of rubber powder with a particle size of 60 meshes is added through the feeder; after the road petroleum asphalt is pumped into 7000kg, stop adding asphalt, and after all the rubber powder is added, keep the temperature of the asphalt at 140-150°C, at 1000-1200rpm After stirring at a stirring speed for 0.5-1 hour, continue to place it in the reaction kettle for 4 hours, and keep the temperature at 140-150°C.

[0039] Then add 50kg of Yanhua 1401SBS. The SBS was homogenized and emulsified by two German SIEFER colloid mills before adding. The gap ...

Embodiment 2

[0042] This embodiment is also to prepare a kind of environment-friendly rubber asphalt with stable storage performance, and the specific operation is consistent with embodiment 1:

[0043] Weigh 700g of Korean Ssangyong 70# road petroleum asphalt, heat it to 140°C, slowly add 300g of rubber powder with a particle size of 40 mesh, turn on frequency conversion stirring, control the stirring rate at 1200rpm, keep the temperature of the asphalt at 140-150°C, and stir for 0.5 After ~h, place it in an electric blast oven at 160°C for 4~6h. Then, add 5g of Dushanzi T161B SBS, and use an experimental emulsification shear disperser at a shear rate of 4000-5500rpm to shear and disperse for 0.5-1h. Finally, add 1.0 g of sulfur flakes, and stir for 2 hours at 140-160° C. at a stirring rate of 1,000 rpm to obtain finished rubber asphalt, which is set aside.

Embodiment 3

[0045] This embodiment is also to prepare a kind of environment-friendly rubber asphalt with stable storage performance, and the specific operation is also consistent with embodiment 1:

[0046] First weigh 720g of Korean SK70# road petroleum asphalt, heat it to 150°C, slowly add 280g of rubber powder with a particle size of 60 mesh, turn on the frequency conversion stirring, the stirring rate is 1200rpm, keep the asphalt temperature at 140-150°C, and stir for 0.5-1h After that, place it in an electric blast oven at 160°C for 6-8 hours. Then, add 8g of LG411S SBS, and use an experimental emulsification shear disperser to shear for 0.5-1 hour at a shear rate of 4000-5500 rpm. Finally, add 1.0g of sulfur flakes, control the temperature at 140-160°C, and stir for 4 hours at a stirring rate of 1200rmp to obtain the finished rubber asphalt, which is ready for use.

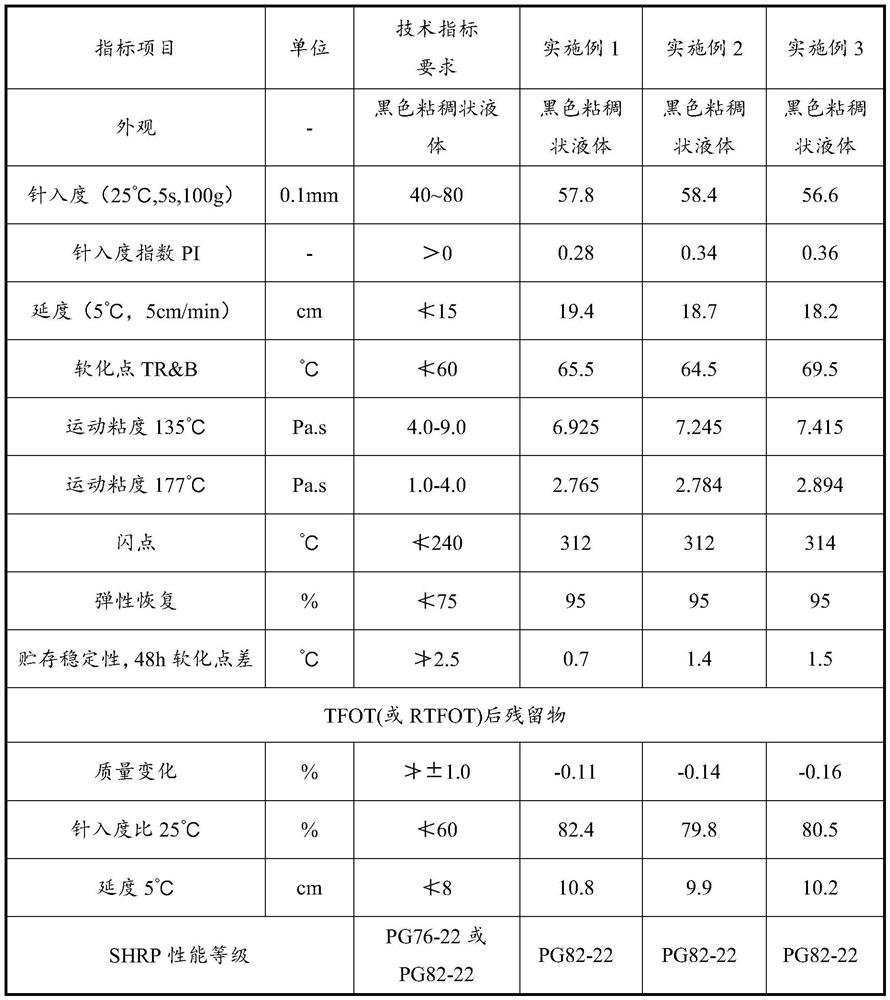

[0047] Embodiment 4 effect example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com