Transcatheter aortic valve and preparation method thereof

A technology of aorta and valve, which is applied in the field of medical devices, can solve problems such as coronary artery blockage, reduce the risk of being blocked, have a wide range of applications, and solve the effect of easy blockage of the coronary artery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

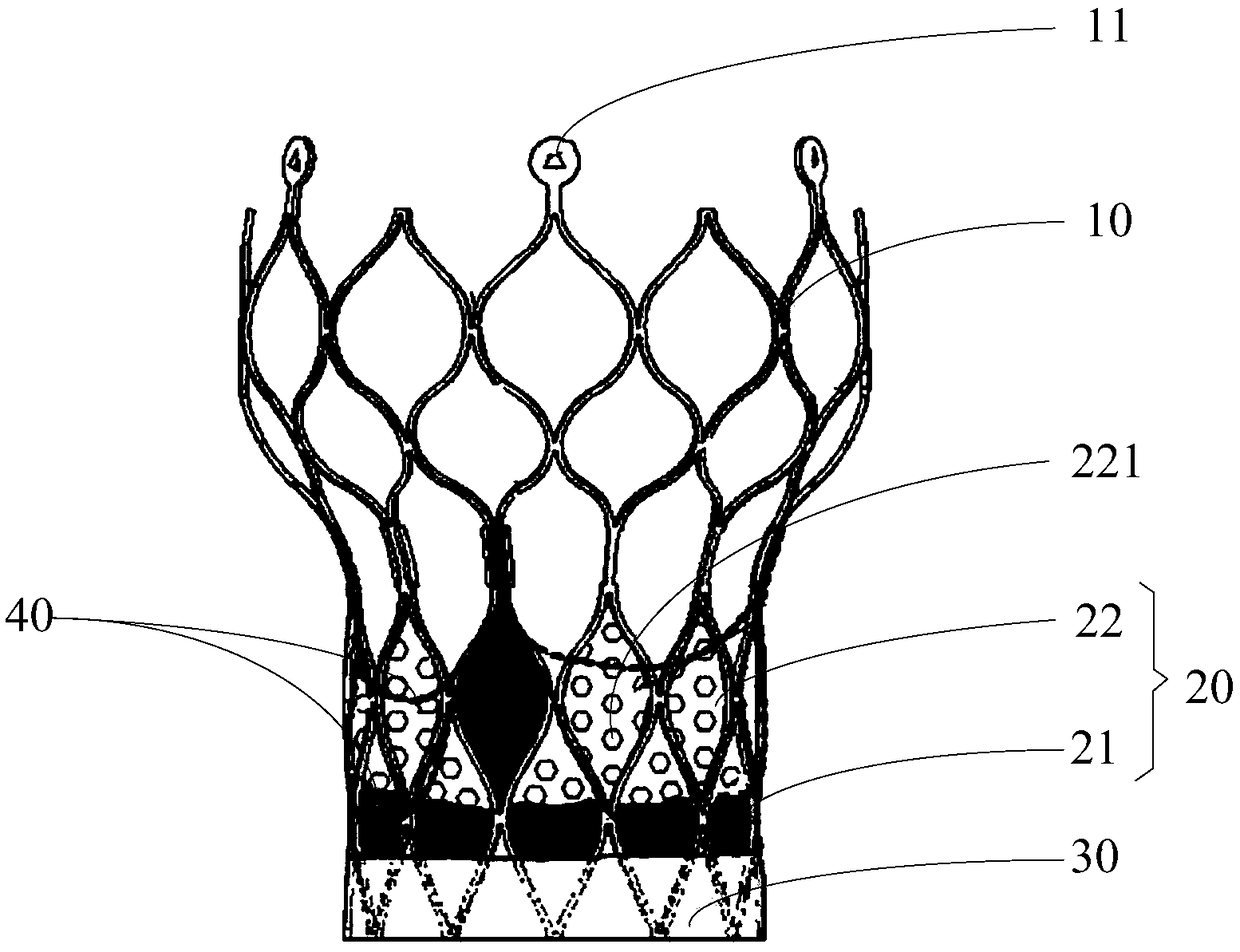

[0043] image 3 Schematic diagram of the structure of the transcatheter aortic valve provided in Embodiment 1 of the present invention, Figure 4 A schematic structural view of the valve frame in the transcatheter aortic valve provided in Embodiment 1 of the present invention, Figure 5 It is a schematic diagram of the expanded structure of the valve skirt in the transcatheter aortic valve provided by Embodiment 1 of the present invention, Figure 6 A schematic diagram of the enlarged structure of the mesh in the valve skirt of the transcatheter aortic valve provided by Embodiment 1 of the present invention, Figure 7 Another enlarged structural schematic diagram of the mesh in the valve skirt of the transcatheter aortic valve provided by Embodiment 1 of the present invention;

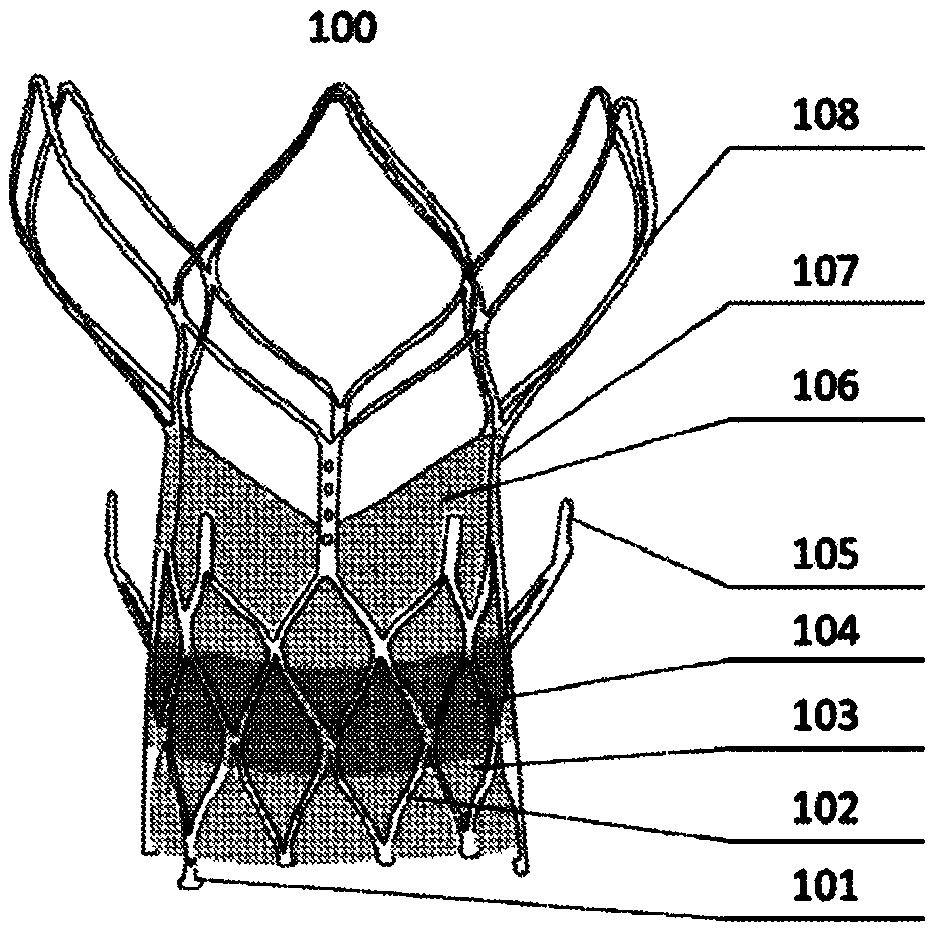

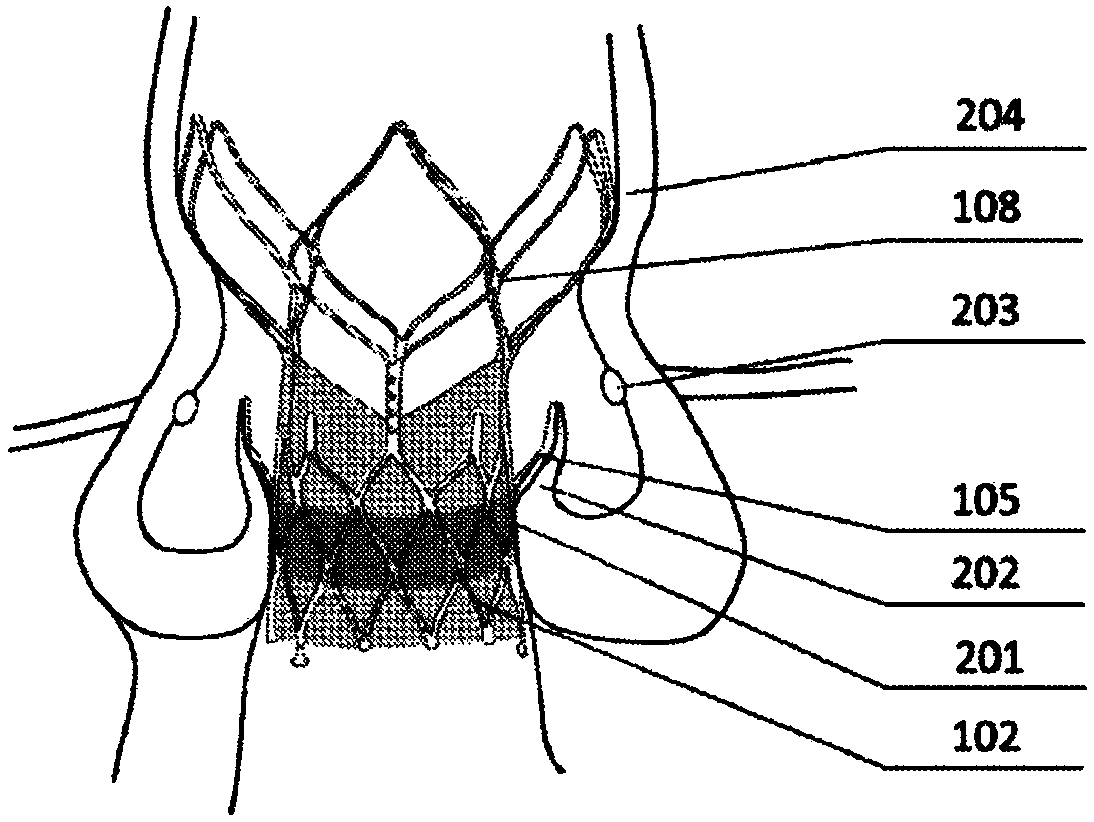

[0044] This embodiment provides a transcatheter aortic valve, referring to Figure 3-7 As shown, the transcatheter aortic valve includes: a radially expandable mesh valve frame 10, a valve skirt 20 ...

Embodiment 2

[0068] Figure 8 A schematic structural diagram of the transcatheter aortic valve provided in Embodiment 2 of the present invention.

[0069] The difference between this embodiment and the above-mentioned embodiments is that in this embodiment, the valve frame 10 is specifically a balloon-expandable metal stent, and the valve frame 10 is specifically made of nickel-titanium alloy, stainless steel or cobalt-chromium alloy through laser engraving, electrochemical polishing and The radially shrinkable and expandable mesh valve frame 10 made by heat treatment, that is, in this embodiment, the material of the valve frame 10 can be nickel-titanium alloy, stainless steel or cobalt-chromium alloy. During production, laser engraving and electrochemical polishing are used. and heat treatment process to make the valve frame 10.

[0070] Among them, in this embodiment, the transcatheter aortic valve is specifically compressed into the balloon-expandable valve catheter by a crimping devic...

Embodiment 3

[0072] The present embodiment provides a method for manufacturing the above-mentioned transcatheter aortic valve, and the specific method includes the following steps:

[0073] Step 1): Sewing a plurality of leaflets 40 in the lumen of the valve holder 10;

[0074] Among them, before step 1), it also includes: the valve frame 10 is laser-engraved, electrochemically polished and heat-treated to make a self-expandable or balloon-expandable metal stent, and inlaid on the valve frame 10 to indicate the valve skirt. 20 Marking points 12 for the positions of the mesh holes 221. At the same time, when the valve frame 10 is a self-expanding metal stent, a plurality of auxiliary fixing devices 11 are formed on the top of the valve frame 10, and the auxiliary fixing devices 11 are used to connect with the delivery system.

[0075] Wherein, in this embodiment, the number of leaflets 40 is specifically 2-6, preferably 3, and the leaflets 40 are specifically made of animal pericardium such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com