Method for preparing adsorption decoloring agent with photocatalytic function

An adsorption decolorization and photocatalytic technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, adsorbed water/sewage treatment, etc., can solve the problems of low adsorption capacity and large amount of decolorizing agent, so as to reduce the pollution load and improve the Utilization rate, the effect of facilitating subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

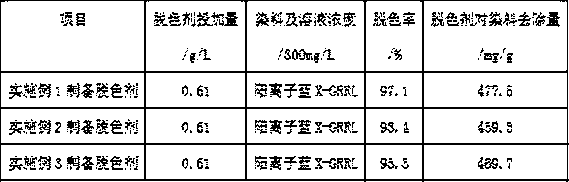

Embodiment 1

[0028] (1) Add an appropriate amount of 200-400 mesh powdered sulfonated coal to the high-concentration water-based ink printing wastewater, stir and react, and use the exchangeable ions ionized by the sulfonated coal to suppress the ionizable group of the water-soluble binder in the wastewater The degree of ionization of the cluster reduces its solubility and destroys the stability of the connecting material, so that the extractable substances in the wastewater just condense into insoluble fine solid particles, and at the same time the exchangeable ions combine with the amine (ammonia) in the wastewater to promote ion exchange and fix the wastewater. Amines (ammonia);

[0029](2) Stir the wastewater at high speed (240r / min) to prevent the flocculation of the fine solid particles and keep the waste liquid mixed evenly. Use ultrasonic treatment and heat at the same time, slowly decelerate the stirring (50r / min), and gradually make the fine solid particles together with the fixed...

Embodiment 2

[0035] (1) Add an appropriate amount of 200-400 mesh powdered sulfonated coal to the high-concentration water-based ink printing wastewater, stir and react, and use the exchangeable ions ionized by the sulfonated coal to suppress the ionizable group of the water-soluble binder in the wastewater The degree of ionization of the cluster reduces its solubility, destroys the stability of the binder, and makes the extractable substances in the wastewater condense into insoluble fine solid particles. At the same time, the exchangeable ions combine with the amine (ammonia) in the wastewater to promote ion exchange and fix the amine Amines (ammonia);

[0036] (2) Stir the wastewater at high speed (300r / min) to prevent the generated fine solid particles from flocculating and keep the waste liquid mixed evenly, use ultrasonic treatment and heat at the same time, stir slowly (30r / min), gradually make the fine solid particles together with the fixed organic amine The sulfonated coal is bon...

Embodiment 3

[0042] (1) Add an appropriate amount of 200-400 mesh powdered sulfonated coal to the high-concentration water-based ink printing wastewater, stir and react, and use the exchangeable ions ionized by the sulfonated coal to suppress the ionizable group of the water-soluble binder in the wastewater The degree of ionization of the cluster reduces its solubility, destroys the stability of the binder, and makes the extractable substances in the wastewater condense into insoluble fine solid particles. At the same time, the exchangeable ions combine with the amine (ammonia) in the wastewater to promote ion exchange and fix the amine Amines (ammonia);

[0043] (2) Stir the wastewater at high speed (240r / min) to prevent the generated fine solid particles from flocculating and keep the waste liquid mixed evenly, use ultrasonic treatment and heat at the same time, stir slowly (40r / min), gradually make the fine solid particles together with the fixed organic amine The sulfonated coal is bon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com